Archroma purchases three VCML pilot coaters

Archroma has acquired the three pilot coaters for its global Centres of Innovation in Spain, India and the US.

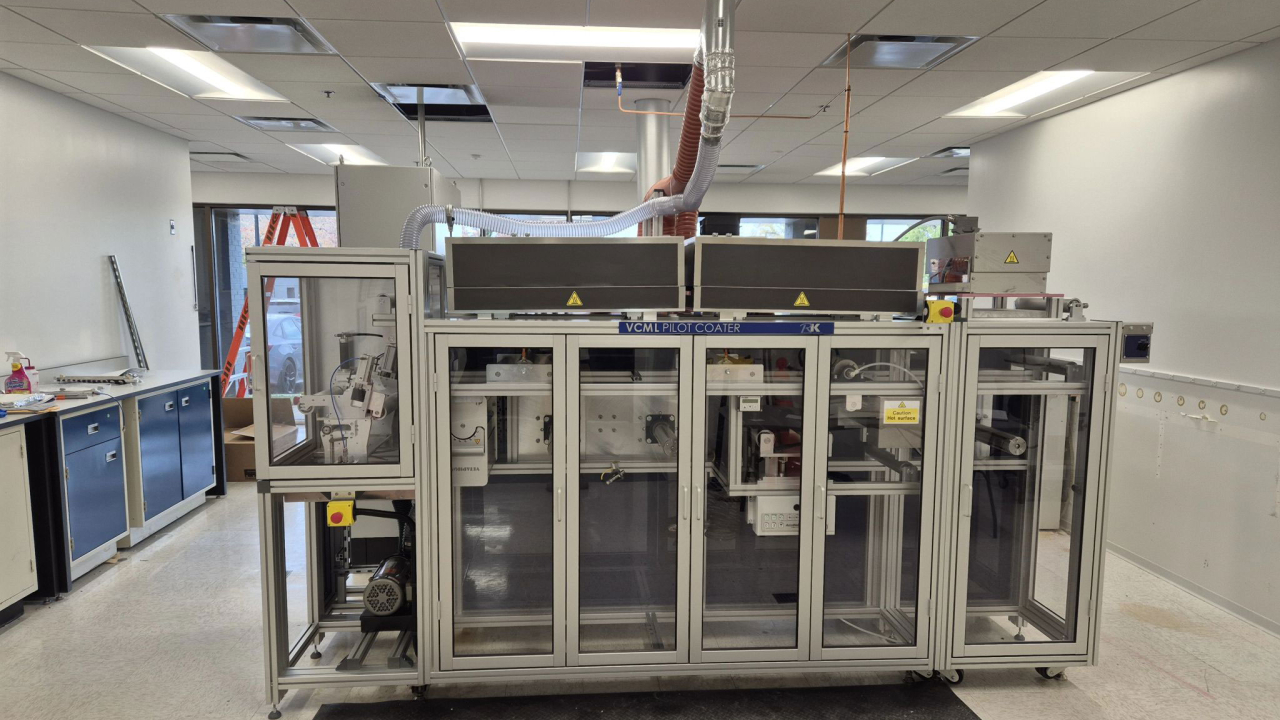

Archroma Packaging Technologies, a global provider of coatings, adhesives, sealants, colorants, and process chemicals, has taken delivery of three VCML pilot coaters designed and developed by RK Print Coat Instruments.

The coaters have been delivered to the new Archroma Packaging Technologies global Centers of Innovation (COI) and are part of the development of sustainable materials.

The three Archroma Packaging Technologies global Centers of Innovation in Mumbai, India, Prat, Spain and Charlotte, North Carolina, US are strategically sited within regions and countries showing dynamic growth in product sectors such as fibre and board packaging and biobased materials, tape and labels, along with specialty and graphic papers; flexible packaging and wood.

Dinakar Gnanamgari, vice president Innovation and Portfolio Expansion, said: 'Archroma Packaging Technologies partnered with RK Print Coat Instruments because it underscores our commitment to provide reliable and scalable research and development – helping brands, converters and mills trust our chemistries to deliver consistent results at scale.'

The Center of Innovation (COI) in Mumbai will focus on providing sustainable and value-added results to serve essential markets such as flexible packaging and wood in the Asia Pacific region.

The COI at Prat in Spain will focus on the tapes and label, specialty and graphic paper sectors and is equipped with laboratories and equipment such as the VCML to support customers in advancing performance, circularity and sustainability of packaging.

The third Archroma Packaging Technologies COI in Charlotte, North Carolina, US, will focus on fibre and board packaging and biobased materials to support continued product development for the circularity and sustainability of packaging.

The VCML pilot coaters are capable of direct gravure, meter bar, and air knife. These highly versatile VCMLs also enable operatives to laminate when using pressure-sensitive adhesives (PSA's).

The machines are similar, so that each COI can replicate results from another plant if needed.

Web control and web tension are via a load cell for closed-loop regulation. Edge guides are included, and the VCMLs in this instance are fitted with two hot-air impingement dryers and a 2.5 kW infrared dryer.

The short-run capability of the VCMLs, together with the coating applicator technology provided, enables coating of various barrier and other functional coatings.

It is of note that packaging technologists tread carefully to ensure that the permeability or barrier properties of the packaging material are appropriate. Barrier critical properties that may be required for paper packaging, tape and labels, flexible packaging include humidity control, oxygen permeability, heat resistance, air tightness, etc.

There are many coating applicator methods to consider. The reverse gravure coating technology supplied with the VCML for Archroma Packaging Technologies pilot coaters is one option. With its extensive wet-coat range, reverse gravure offers uniformity and freedom from pinholes. The absence of pinholes is vital, as they negate the effectiveness of any barrier in place.

However, while the reverse gravure nip method is a contender for applications in areas such as fibre and board, and for reverse gravure in flexible packaging, each of the other coating methods supplied contributes to product viability.

Every coating technology has its strengths and drawbacks, but the decision on which coating method is most effective is often made through experimentation and evaluation of cost, end-use requirements, and other factors.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.