Combination masters

Looking back to the first issues of Labels & Labeling in 1978, and comparing historically what happened at Gallus during that time, it is clear that 40 years ago the course was set at Gallus which still shapes and drives the company today. A look into the rearview mirror 40 years ago also shows an interesting overview into Gallus’ company history, involving almost all the printing processes the narrow web printing industry knows.

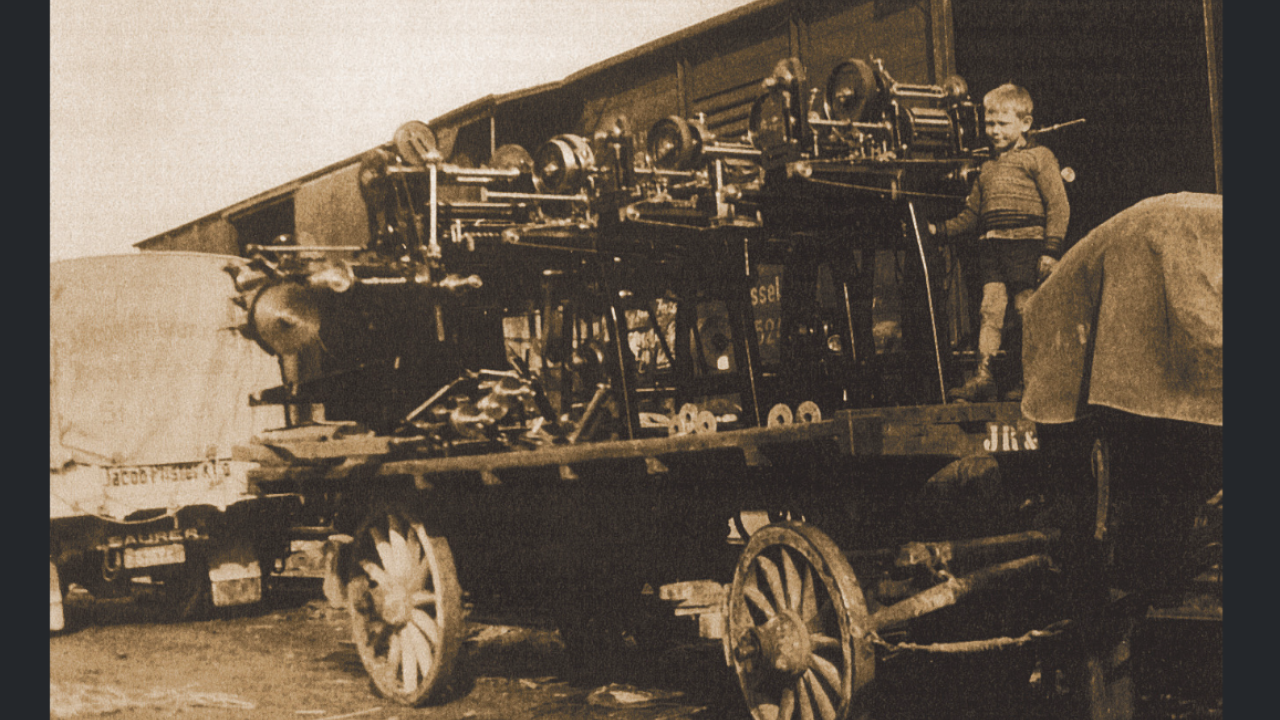

It all began in 1925 with a small letterpress developed by Ferdinand Rüesch-Baur – the founder of Gallus – for the textile industry to produce sample tags, which up to this time had still been marked, piece by piece, by hand. Already then the philosophy was: from roll to finished product in a single production operation.

Thus the first ‘Gallus’ label printing machine was built. Obviously Ferdinand Rüesch-Baur already suspected at that time that a promising market could be opened up for this newly developed letterpress printing machine. Patents were immediately applied in Germany, the UK, France and Switzerland.

For the next decades letterpress printing was the leading process in label production until 1944, when gravure made its entry in tag-label printing. A 1-color gravure cross printing unit enabled a larger web format on the Gallus Q12.

Milestone

In 1953 the next milestone was set by launching the Gallus Q33, the first label press for the production of pressure sensitive labels with two printing units.

With the beginning of the 1960s, the importance of pressure-sensitive labels was increasing, and Gallus brought a world-first innovation to the label printing industry market – the segment punching unit. The innovation was the angular setting of the segment stamp unit which made it possible to reduce the pressure used in the punching out of self-adhesive labels. This method reduced the risk of stamping the backing paper, allowing production speed to be considerably stepped up.

By launching the A130 and A160, also in the 1960s, the first rotative flexo label presses from Gallus were introduced to the market. The flexo plates changed in this time from vulcanized flexo plates to nylon printing plates. The Gallus A130/A160 presses were equipped with different in-line finishing features such as numbering unit, perforation, lamination, a rotary die-cut unit with matrix longitudinal and transverse cutters.

In the 1970s there were decisive and diverse developments in the company’s machine designs. This was evidenced by the Gallus T180 but also the Gallus V330. The Gallus T180 was Gallus’ first modular and format variable design, expressing the principles of combination printing within one press and combining translative letterpress, as the leading printing process, together with translative flat screen, hot foil embossing, lamination and die-cutting. Later, UV curing was integrated in this press.

Also in the 1970s, the Gallus V330 O was launched as the first variable offset label press, designed particularly to meet the high quality demands of the cosmetics industry.

The famous era of the Gallus R160 and Gallus R200 began at the end of the 1970s. Presented at Grafitalia in 1979, it caused a great stir with its swivel letterpress, UV-interim curing and fast flat die-cutting unit. This format variable rotative letterpress was running with a speed of 80m/min and became one of the best-selling label presses in the world, with 1,135 machines sold over a period of more than ten years.

By the beginning of the 1980s, the market demanded a wider 10-inch machine. The Gallus R160/R200 then evolved into the Gallus R250, an in-line label printing press. The modular platform principle offered great flexibility to the label printer, containing both flexo and letterpress printing units, UV curing, rotative or flat die-cutting, front and backside printing, all with a maximum speed of 150m/min. The machine was then available in flexo or letterpress as the main print process.

Pioneering hybrid printing

At that time Gallus also became involved with the development of digital print for the first time, working with partner companies. Already in 1985 a non-impactprinting system called Gallus Magnaprint was developed.

Four years later in 1989, a Presidax dry toner unit was introduced on a Gallus R200. Exactly 20 years ago, in 1998, Gallus took the first step towards digital printing and launched its first hybrid digital printing press.

The Gallus Indigo DO 330, based on the Indigo electric toner system invented by Benny Landa, was a label printing machine that digitally reproduced the printed image on a plate cylinder using the electrophotography process, and then applied the image to the substrate via a rubber blanket, similar to offset printing. But success did not come – the market did not yet seem ripe for this technology.

Now, twenty years later, Gallus entrenched its position in the digital market with the Labelfire, launched in 2014. The Labelfire continues Gallus’ history of combining print processes into one in-line process. Upstream and downstream of the 7-color UV inkjet unit, different in-line finishing and embellishment processes can be integrated, such as flexo for spot colors and varnishing, screen printing, cold foil, lamination and a semi-rotary die-cut unit.

The Gallus Smartfire introduced this year to the market is an entry-level digital label press with water-based thermal DoD-inkjet technology by Memjet.

The 1990s had not only been shaped by the early digital developments. Leading the way for the industry was the launch of the Gallus T250 in 1992 with the first direct-driven servo motors.

At Labelexpo Europe in 1999, almost 20 years ago, Gallus introduced the RCS 330. At the beginning of the 21st century this machine already enabled an unprecedented variety of processes such as letterpress, screen, UV and WB flexo printing, hot and cold foil embossing and coating. Later, offset printing was also introduced on the Gallus RCS and today even a gravure printing unit is available for this press. Another technical historical milestone of this machine was – and still is – the process change without web interruption.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.