Tamar Packaging Solutions blazes trail in folding carton

Tamar Packaging Solutions shows how in-line converting and problem-solving can create a powerful niche in the folding carton market.

Paul Baker in front of Edale FL5 carton press with in-line flatbed cut-crease module

Located in the stunning Tamar Valley in Southwest England, Tamar Packaging Solutions has carved a successful niche in the folding carton market using Edale in-line flexo technology.

The company specializes in direct food contact carton board products for the FMCG market, including printed U-cards, base cards, tray inserts and folded/glued cartons and sleeves, primarily for the bakery markets.

Privately owned Tamar Packaging Solutions is run on a day-to-day basis by technical operations manager Paul Baker.

Baker has a long history in the labels industry. Before joining what was then Tamar Labels in 2011, he had worked for 12 years at Chesapeake’s Yatton, Bristol site, working his way up from rewind department to pre-press, then Mark Andy operator.

In 2014, Tamar Labels sold off the labels side of the business and stripped out the Mark Andy, Nilpeter and HP Indigo presses, leaving only a solitary 4-color Edale Sigma press, which mainly produced U-cards for pastry products.

Tamar Packaging then found itself with a unique opportunity to start the business again, ‘pretty much from scratch’, Baker says.

Focusing only on paperboard and carton products, by 2017, the business was strong enough to install a new Edale FL5-510 press.

Covid proved a turning point. ‘We grew through Covid by taking on a lot of new customers,’ recalls Baker. ‘We took risks by purchasing board materials we had no orders for, but soon started to roll through it.’

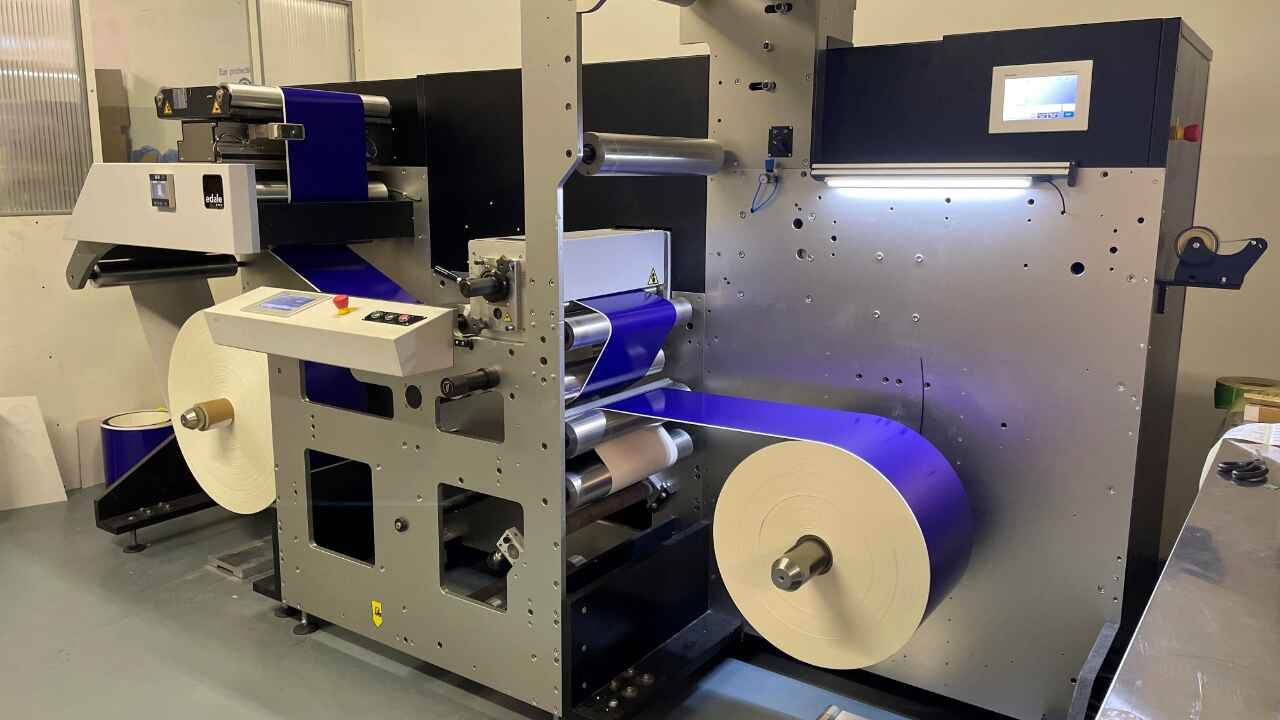

At the height of the pandemic in 2020, Tamar purchased a 2-color Edale FL5 mainly for blank card work, and an Edale slitterrewinder to slit down master rolls. In 2022, Tamar added another 8-color Edale FL5 carton press.

Flatbed in-line

Tamar Packaging’s most recent acquisition is an Edale FL5 equipped with in-line flatbed die-cutting/creasing. The new FL5 has a wider web width of 530mm and can handle thicker board materials up to 700 microns.

Like Tamar’s other FL5 presses, the machine is equipped with Edale’s full automation package, including AiiR autonomous inking, auto impression and print registration, along with jumbo unwinds, rail-mounted turnbars, UV and IR drying/curing capability, BST monitors and shingling delivery tables.

“Tamar Packaging Solutions’ real super power is the ability to solve customers’ performance and sustainability challenges using coating technology”

Where Tamar’s existing FL5 presses are equipped with rotary die-cutting, the new machine is configured with an in-line flatbed die-cutting/creasing module.

‘The only problem we found with rotary tooling is getting the high level of crease,’ explains Baker. ‘Rotary is great for perfing and creasing U-cards, but not for folding cartons. You can only achieve a high level of creasing with solid male and female dies, but these can be very expensive for a set, which means you need a very long running job to make it cost-effective. Up to now, we have potentially been missing out on a lot of folding carton work. So, the purchase of the flatbed die-cutter opens up new markets for us.’

Finding a niche

The folding carton market is dominated by highly consolidated groups using sheet-fed offset technology and multi-stage finishing. Tamar Packaging Solutions has thrived by working out where in-line flexo can, and cannot, compete.

Explains Baker: ‘It’s been a big learning curve for us. Initially, we were trying to quote on everything. We found that we couldn’t compete on the bigger blank sizes when going up against the litho guys because we can only get two to three blanks on one repeat. But, if you start to find the sweet spots where the format size fits and where we can print and coat in-line, we can take the edge back. But it took a long time to get there.’

Tamar Packaging’s key competitive advantage against litho is the ability to coat, print and crease/die-cut in one pass. ‘On the Edale FL5 presses, we can coat and then print up to seven colors on the other side at speeds up to 150m/min.

‘Working to customer forecasts, we can forward plan raw materials three to four months ahead whilst normally holding one to two weeks finished stock, therefore being able to react quickly to changes on demand or the need for promotional designs without having to wait for large quantities of old stock to be used up,’ says Baker.

‘With our larger customers, they place forward orders, which we print when it makes most sense for us, then we hold stock that they can call off at 48 hours’ notice. We work in a similar way with our board suppliers, so we can call stock off, including mixed loads.’

In 2023, Tamar Packaging acquired its first Vega off-line straight gluing machine, allowing the company to take this critical process step in-house. The Vega can handle a wide variety of box sizes and styles, from cartons to sleeves.

Coatings expertise

Tamar Packaging Solutions’ real superpower is the ability to solve customers’ performance and sustainability challenges with coating technology.

In the bakery sector, for example, grease migration traditionally requires the use of a plastic barrier to protect the board from contamination. Working with its coating suppliers,

Tamar now offers a selection of grease and moisture-resistant varnish barriers specifically designed for direct food contact, eliminating the need to use plastic.

‘Coatings and specialist barriers which we apply in-line are an absolute game-changer for us,’ says Baker. ‘Where coatings also have to work as a heat seal layer, we can make sure our coatings match the heat-sealing properties of PE.’

Tamar used to buy barrier materials for these applications. ‘But now we apply our own coatings and come up with levels of coating that work with different products. We know which anilox to use for which application. So, every product has its own level of coating.

On our Edale presses, we put barrier coating on one side, flip the web over and print on the other side and then die-cut all in one pass.’

Coatings suppliers have collaborated with Tamar Packaging to test their new technologies.

‘We work closely with our board and coating suppliers, which often involves a lot of trial and error, to get the best products for our customers. We have found that some customers are buying boards that are over-specified for their products, where we can apply coatings to just the level they need. Once customers have successfully tested a particular coating, we record that information, so each individual customer has their own specification.’

Continues Baker: ‘Our main push is toward using natural barriers, which do not impact recycling. Our customers are also asking us to test for compostability. There is still a lot of work to do on certain products to make them fully recyclable, but we will get there.’

In 2022, Tamar Packaging became FSC-accredited for the supply of boards suitable for direct and indirect food contact.

“Tamar Packaging Solutions has thrived by working out where in-line flexo can, and cannot, compete”

While bakery packaging is at the core of Tamar Packaging’s business, other end-use markets are also growing rapidly. These include frozen foods, where water-resistant coatings and high-quality graphics are required, and ‘hot food on the move’, with hot cabinet displays becoming more common in supermarkets, forecourts and even vending machines. Tamar tailors the combination of inks, varnishes and carton board to allow the packaging to withstand high temperatures.

The future

It is worth pointing out that the workforce at Tamar Packaging is just 12 production staff.

Such a lean workforce can be largely attributed to the automation on the Edale presses.

‘Automation has taken a lot of the fun out of printing,’ laughs Baker, ‘and servicing has become more difficult.’

Following the installation of the new Edale FL5, Baker has taken on a new production supervisor and is in the process of adding new production staff.

With its unique combination of in-line flexo production, product diversification and coatings expertise, Tamar Packaging Solutions looks set for a bright future in one of print’s most competitive markets.

Food-safe and sustainable

Tamar Packaging’s plant and production operations are optimized for food safety applications, built around an AA-grade BRC accreditation.

The company selects either water-based or low-migration UV inks, depending on the food-contact sensitivity of each job. Says Baker, ‘We select the inks, DFC inks and coatings on a case-by-case basis because of the wide range of scenarios such as length of time the product comes into contact with the card, types of food and the moisture levels within the product. We only use UV inks on non-direct food contact surfaces. All our coatings are water-based, so they are perfect for direct food contact.’

Tamar Packaging also prides itself on being a highly sustainable business. The company has implemented a ducted waste removal system on its carton presses and rewinder. This guarantees the efficient removal of all carton board process waste from the factory, which is then processed by a chopper fan and the waste is subsequently directed into a recycling skip, promoting a zero-to-landfill approach. Additionally, all plastic waste is recycled.

‘Our dedication to minimizing our environmental impact and contributing to the sustainable growth of flexographic printing remains unwavering,’ Baker says.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.