Labeling start-ups

Start-up brands often face several creative hurdles when it comes to labeling and packaging. Indian brand strategist Shivani Parmar says converters can help solve their problems.

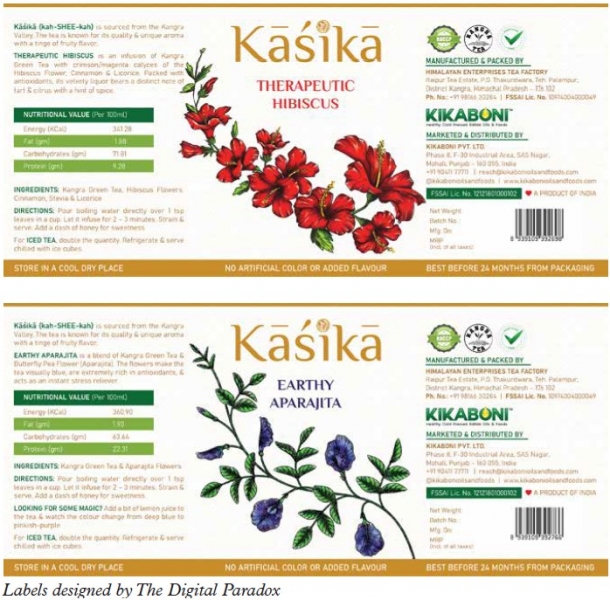

The rise of e-commerce in India is seeing more and more start-up brands cropping up. With increasing competition comes the need for creative labeling and packaging. Shivani Parmar, brand strategist and founder of The Digital Paradox, speaks about the pain points of start-up brands when it comes to labeling and packaging.

Parmar started her career in marketing working with start-ups and SMEs. Instead of focusing just on digital marketing, she wanted to help start-ups all the way from forming a business plan to marketing the end product.

‘It is exciting because it’s creative and lets you build something. Your goal is not limited, it requires you to look at the vastness of things available to you and that excitement is what keeps it going,’ she says.

‘A lot of the time, start-ups know what they want and where they want to go, but the process gets a little lost. We help them put their vision together in a manner that consumers can understand what they

are offering.’

A young entrepreneur and rally car driver, Parmar used to work in Dublin. On returning to India, she worked with companies such as leading advertising agency DDB Mudra. In 2017, she established

The Digital Paradox.

She says that the problems of start-ups when it comes to packaging are present from the very beginning. Understanding that certain types of substrates and adhesives are made for certain labeling

applications can be a challenge. ‘For example, food such as something with oil can weaken the adhesive of a label and it might come off.’

Start-up brands can miss out on looking at the different variety of substrates available in the market. They take design references from existing brands but are unable to differentiate between the types

of materials used. ‘But when you go to manufacturers’ website, you see all different kinds of substrates.’

However, she points out that converters often stock a limited variety of products and recommend them based on availability. In the cut-throat competition of the FMCG space, start-ups need support and guidance to create a product that can compete with international brands. Converters could help them understand how to achieve it.

‘I go to converters and I know what kind of conversation I would like to have with them to understand what is needed. We try to bridge the gap so that start-ups can understand how their label is made and what kind of material is used. With my learning about different kinds of substrates available, I try to help brands take a decision.’

She says that her father, print industry veteran Vimal Parmar, has been supportive. ‘Thanks to my father, I have understood some part of the industry and how it works.’

If young designers know how different materials can be printed and embellished and how a design might look on each of them, they could enhance the result

The problem extends to young designers as well, who could, in Shivani Parmar’s opinion, design better packaging when equipped with knowledge of the kind of substrates, adhesives and finishing options available. ‘If young designers know how different materials can be printed and embellished and how a design might look on each of them, they could enhance the result.’

The Digital Paradox has an in-house design and production team but is open to collaborating with like-minded people in case a brand needs more than the company can offer.

‘I spoke to one of the designers when she was a student. Her professor told her to get a print. The student was surprised to see so many types of print and designs when she visited a print shop.’ This knowledge is crucial in design.

Visualizing the brand

The process of creating a label starts by visualizing the brand. ‘Then we pick colors. At this point, we design a label with our in-house designer. Then we research competitors in the market. How can

you be different from what is already present in the market? That is when the whole process begins. The substrate is the last thing that we think about. I think that it should be discussed earlier in the process. The knowledge would be useful to design something better than what we currently do.’

She wonders if the process could be reversed. ‘They could choose the best substrate, printing and, based on that, the design. But right now it happens the other way. Beyond that they do not have any

understanding of how they can go about printing,’ she explains.

The knowledge of different kinds of materials available and their functionalities and applications could enhance the function of a label. It needs to come from converters and manufacturers.

Parmar adds that helping young designers understand margins could also be useful. ‘Each printer has different margins. How can designers optimize a label accordingly so that it is printed without

wasting paper? How can they use the extra paper?’

Merely figuring out the design is just half the battle. The other half of the process is understanding how the design will translate to print. Then comes the problem of color. ‘Understanding what you

see on digital and what you see in print is vast extremes. Start-ups do not understand that either.’

Printing using different materials and inks can produce substantially different results. ‘They lack the awareness of how a logo and its colors are going to look, for example, on a yoga mat, t-shirt or label and packaging. This knowledge could help promote fresh ideas about what else they could offer to their customers.’

She adds: ‘The details of it, such as font sizes, sub-standardization process – those kinds of guidelines are missing. They could be out there, but it is difficult for start-ups to find them.’

Ensuring that the correct information is printed on a label can also be a challenge. Taking food regulations as an example, Parmar says that there are Food Safety and Standards Authority of India

(FSSAI) guidelines about the information to be put on the label.

‘Specially if it’s an organic product. Understanding what an organic product is, the details of the allergens and the importance of stating nutritional value, ingredients, manufacturing date, packaging date and best before also needs to come in. India is different from the international market. In India, we mention the approximate time by which it expires in contrast to the West that prints the exact date. The regulations in the food industry vary so much from the West. When I saw the list of allergens that needs to be mentioned on the label on the European website the list was pages and pages but for India, it was just mentioned in few brackets. It is up to you to figure out what comes under those categories mentioned in brackets.’

She adds that as awareness is growing, brands are gradually mentioning the important details on packaging. But ensuring that all the required details are mentioned on a label and making it fit particular label sizes is a challenge for start-ups. ‘The smaller the bottle, the smaller the label. Then you need to figure out how much crucial information you can put on it.’

Having experienced her share of botched print, she asks what kind of communication is needed to help printers understand what we want and if they need to tell us more about what we want?’

Education

According to Parmar, education for everyone involved in the process of creating a label is crucial. ‘Not all of us can be experts. There already are experts which is why we try to go to them and that is where converters could come in. They are more up to speed with the developments in the industry.

‘Start-ups are just starting. They may not have got into the depths of thinking how to print a label. They might not consider the kind of material that goes behind it. They could read about it and watch videos online. But there’s only so much that they can learn from a screen when it comes to printing. You need to see how it looks when it is printed. You need to feel the quality.

‘When start-ups compete with international brands, the label needs to look just as good as theirs, and converters need to help us understand how start-ups can achieve that.’

Converters and manufacturers need to be more approachable for brands that are the end users of their products.

When start-ups compete with international brands, the label needs to look just as good as theirs, and converters need to help us understand how start-ups can achieve that

‘The knowledge of the availability of substrates and understanding of if you have shampoo bottle in comparison to oil bottles, both are bottles at the end of the day, but the product inside will hamper the performance of the label. Maybe the understanding of that could come in. They could guide brands and even educate us.’

She adds that an ecosystem where brands and marketers could go to manufacturers and converters and ask for the best product based on the brand identity could be instrumental in producing quality labels and packaging. ‘We want to understand what our options are. But is there something more they could do to help us be more creative?’

Start-ups tend to keep designs simple because cost comes into play. They need guidance on how they could get the best design at a low cost. Parmar says that these answers could also support start-ups adapt to different packaging styles. ‘Then it’s not just the bigger brands who can afford to create stunning packaging.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.