★You are viewing this content as a subscriber

★Subscribers only

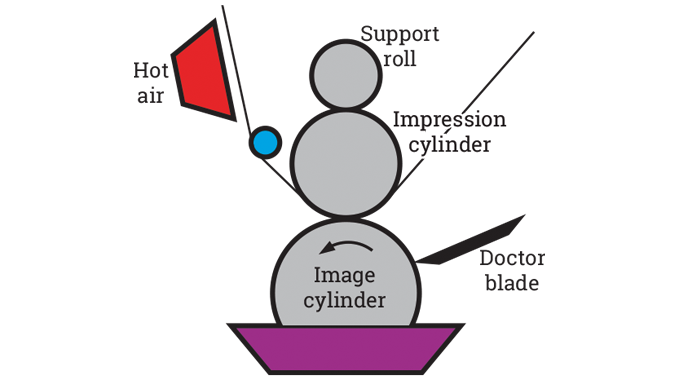

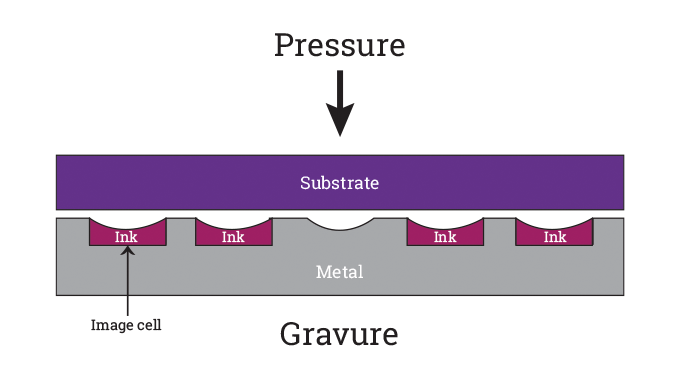

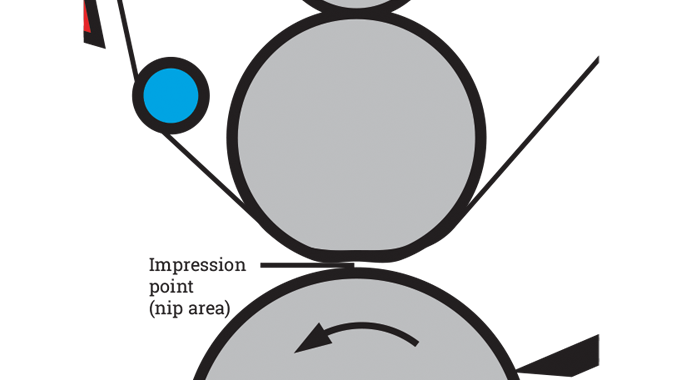

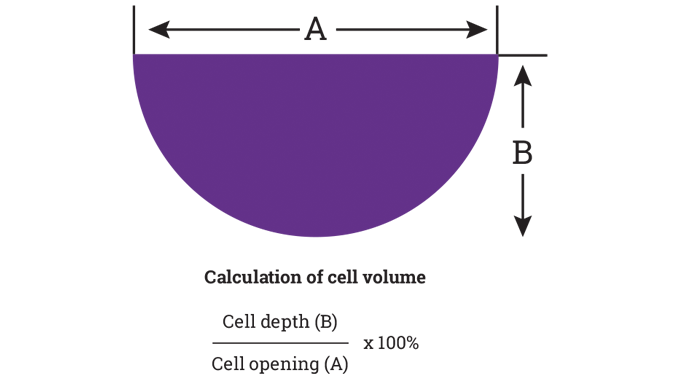

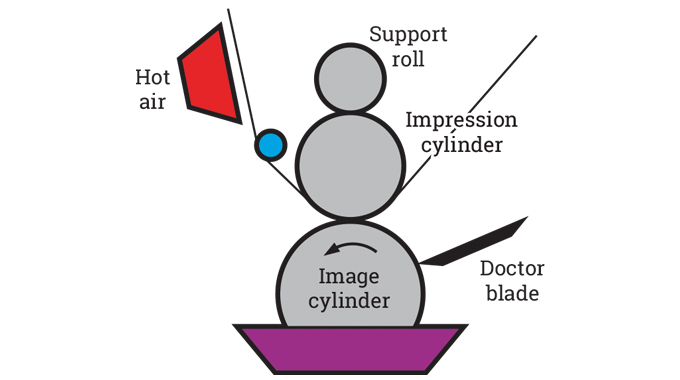

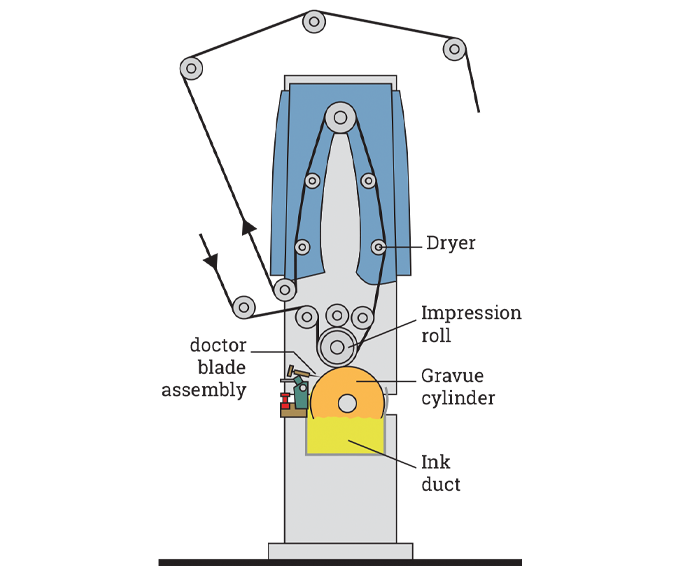

Print processes: gravure printing

Gravure is designed for printing fine tones with a sharp dot formation and offers high quality results on long runs

Intaglio gravure printing originated with the goldsmith engravers in about 1446. The images were hand engraved onto copper, gold and silver and the recessed image was filled with a black ink or enamel known as Niello and then pressed onto paper.

These early prints were used by the goldsmiths to display the range of engravings available to the customer. The goldsmiths not only engraved their products but also developed an etching method useing nitric acid.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.