Amcor installs packaging sector’s first Cool-Therm Turbomiser chiller to aid plastic extrusion

- First chiller of its kind to be installed in the packaging sector; efficiencies exceeding anticipated gains

Cool-Therm has installed one of its new Turbomiser chillers at Amcor Flexibles’ Winterbourne facility in the UK, where it will deliver continuous chilled water required for plastic extrusion.

The Turbomiser chiller developed by Cool-Therm operates on virtually frictionless magnetic bearings, to deliver lower power consumption and reduced carbon emissions.

It is believed to be the first chiller of its kind to be installed in the packaging sector.

In a recent project, Cool-Therm worked closely with staff at flexible packaging manufacturer, Amcor Flexibles Winterbourne, to replace one of the existing chillers at the site, after it had reached the end of its operational life.

Cool-Therm has worked with Amcor Flexibles Winterbourne for more than 20 years, installing and servicing three large chillers at the company’s manufacturing facility on the outskirts of Bristol.

During this time, Cool-Therm has ensured the chillers remain in top condition and perform reliably to deliver the continuous chilled water required by the plant’s plastics extrusion machines.

The “sweet spot” for Turbomiser is considered to be 25-60 percent of load, where, due to its operating characteristics versus conventional chillers, energy efficiency for the delivered cooling capacity is maximised.

Turbomiser is equipped with integral inverter drives, enabling very fine incremental adjustments to be made to precisely match chiller output to cooling load.

Cool-Therm is now working to fine-tune the cooling system to deliver further energy savings to customers.

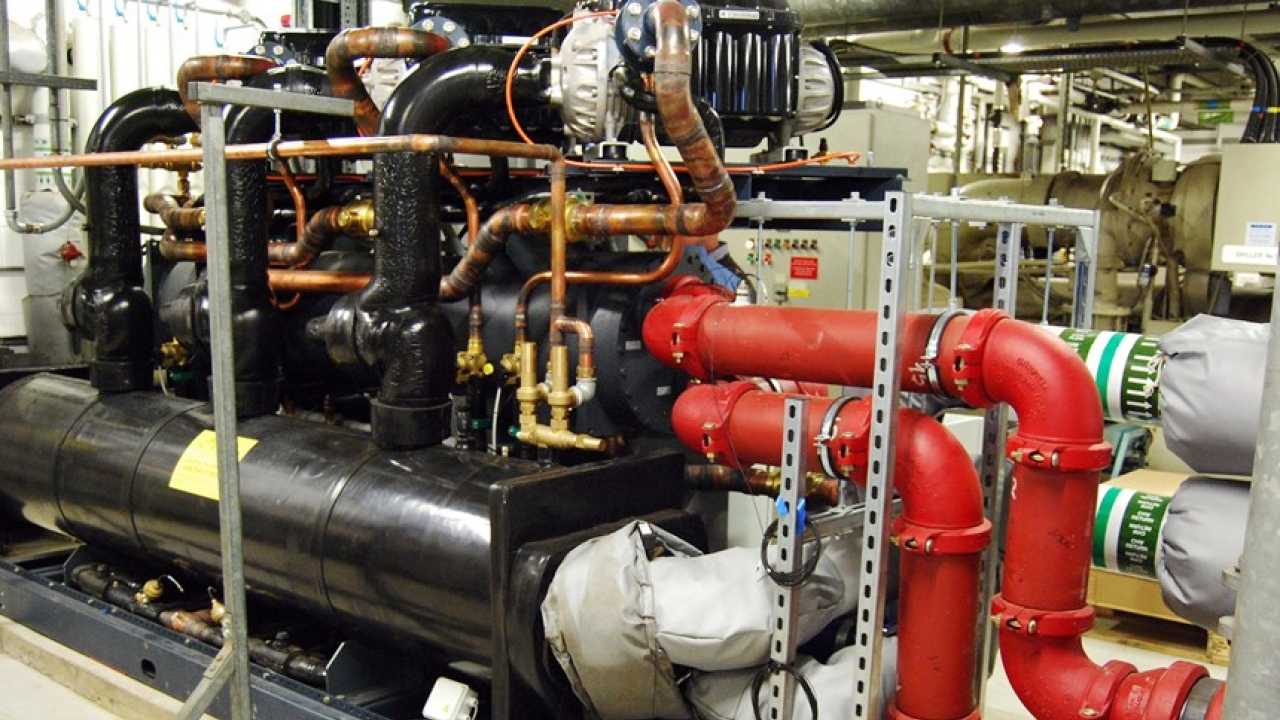

The new Turbomiser chiller at Amcor Flexibles Winterbourne (pictured, above), installed alongside two existing McQuay centrifugal chillers, operates around the clock, all year round.

The new Turbomiser chiller at Amcor Flexibles Winterbourne (pictured, above), installed alongside two existing McQuay centrifugal chillers, operates around the clock, all year round.

Andreij Duma, operations director at Amcor Flexibles Winterbourne, said: ‘Cool-Therm anticipated a 20-25 percent energy saving with the introduction of Turbomiser.

‘However, the performance over the first six months looks even better than this, and the latest figures show a saving of just under 50 per cent.

‘This is an impressive result and we appreciate Cool-Therm’s expert assistance and support in this project and over many years at the facility.’

Ken Strong, managing director of Cool-Therm, added: ‘The period of use so far covers the warm season.

‘We would expect even better efficiency still during winter. Here, Turbomiser can operate at lower condensing temperatures where the efficiency advantages are greatest.’

Read more on Amcor here

Read more about ancillary equipment here

Read more about substrates here

Read more news from across Europe here

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.