Technotrans cleans up Chesapeake’s Leicester plant

- Investment underpins quality and environmental credentials

- Filtration unit extends cleaning cycle from weeks to months

Chesapeake’s pharmaceutical plant in Leicester has invested in pressroom equipment to underpin its quality and environmental credentials.

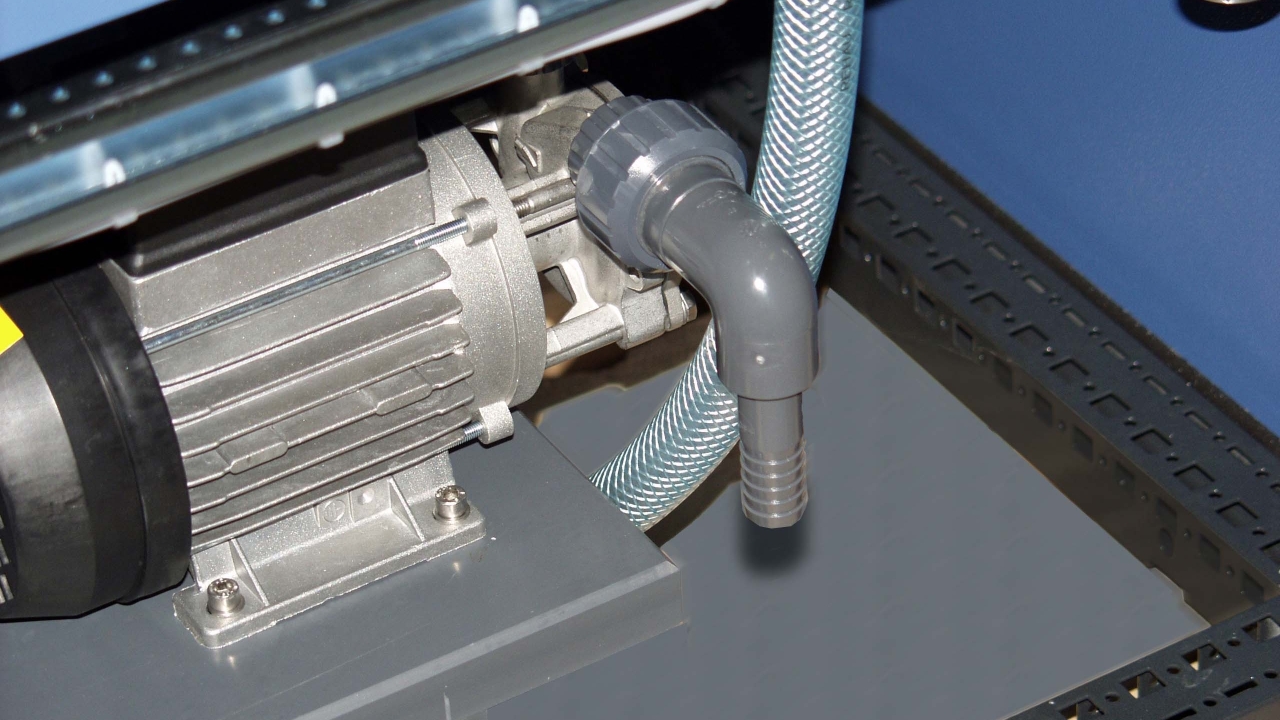

A Technotrans alpha.c combination unit controls both inking and dampening temperature, with an alpha.f filtration unit fitted to its latest 28in six-color Komori Lithrone press.

Consistent temperatures maintain constant ink tack, and ensure clean dampening to allow the company to remove variability from production. This includes scumming, which is a problem with UV inks.

The filtration unit (pictured, top), which removes debris from the dampening, is a prerequisite to reducing alcohol levels, and allows the Leicester plant to operate at a level of just three percent.

The filtration unit has improved the cleaning cycle from three weeks to three months, and while the reduced cost of the chemistry is offset by the investment in filters, there is a reduction in maintenance time.

The filtration unit uses a bypass connection to the dampening solution tank, allowing the solution to pass through a double filter for complete decontamination. The result is lower waste disposal costs and equipment that runs at its optimum level.

Read more on Chesapeake here

Read more about ancillary equipment here

Read more news from across Europe here

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.