Comexi to demonstrate F4FLEXOEfficiency - Stand E205

The new F4FLEXOEfficiency is a new type of CI flexo press designed to cope with the diverse demands of the print for packaging industry, from short run work to expanding opportunities in new markets. The elimination of photo initiators through eCOMEXI solutions, which utilizes EB Flexo technology in high performance flexo printing is an option on the new press

Its capability of printing in high line screens opens the door to markets previously considered out of reach, typically those of gravure printing, but without cost penalty. To cater for the continued decline in run lengths, Comexi has installed a high degree of automation to reduce changeover times and increase profit margins.

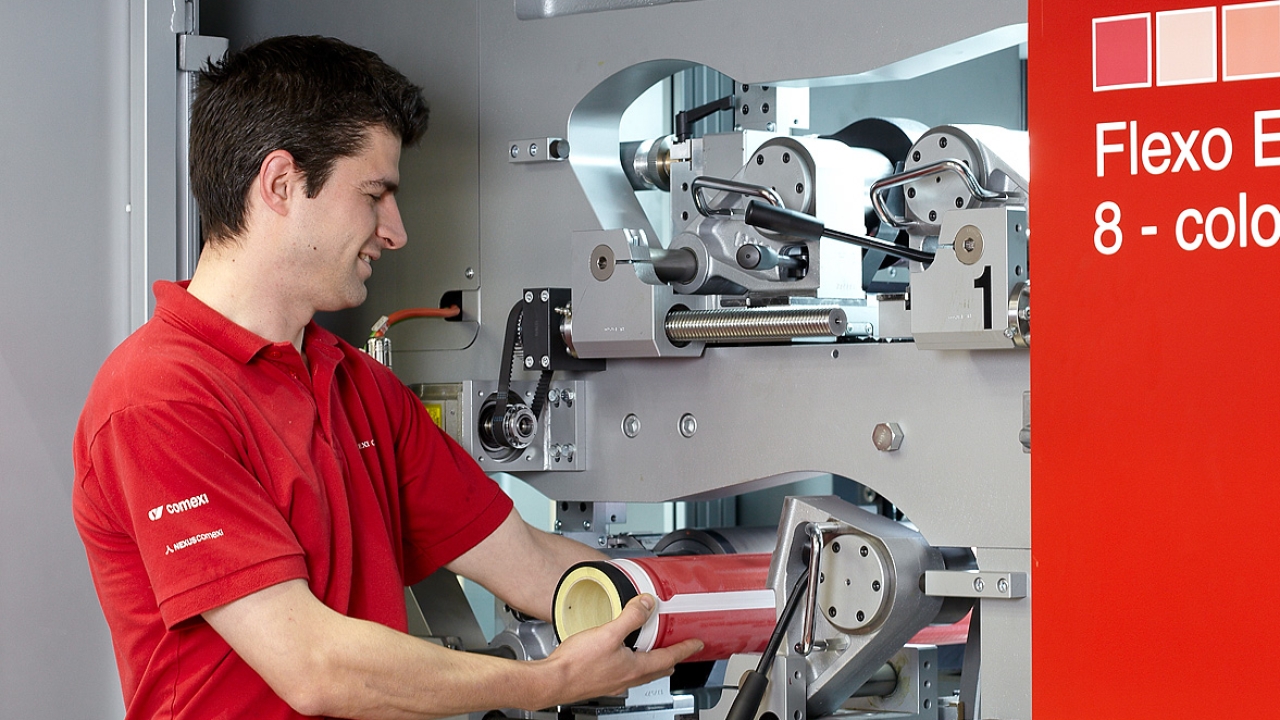

The 8-color press has a new doctor blade chamber support design that reduces change times dramatically and increases accessibility for maintenance. It has web width of 670mm (26.3’’) up to 870mm (34.2’’), with a minimum repeat of 240mm (9.4’’) up to a maximum repeat of 600mm (23.6’’), creating cylinder savings for a direct impact on the cost of the finished product. Top speed is 300 m/min (984 ft/min).

The F4 FLEXOEfficiency press incorporates Comexi’s latest technology for totally automatic pressure and register adjustment. CINGULAR DOT2offers adjustment based on the true print of one 1.5mm dot in less than 90 meters (296 ft).

With the EB option, a curtain of accelerated electrons is emitted towards the web in a vacuum chamber. When the energized electrons hit ink or coating, the curing process happens instantaneously, without the need for a photoinitiator (PI).

The EB process is conducted under an inert nitrogen blanket. The instantaneous cure gives the printer the ability to post-process or ship immediately the stock comes off the press, shortening the time to market. This ability to respond quickly and not have lag time and inventory problems are additional financial and process management advantages of EB curing.

The company describes its F4 FLEXOEfficiency as a new way of flexo printing that has already gained wide acceptance in the market with 10 machines installed in the months since its launch.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.