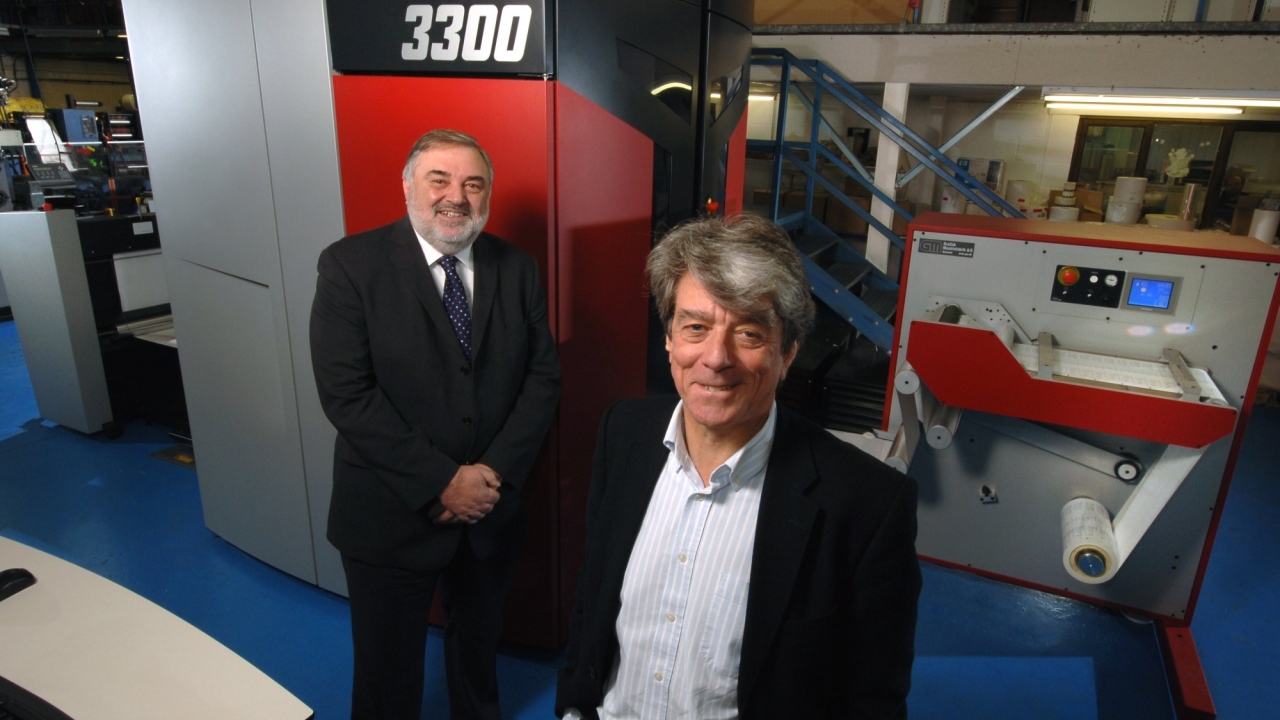

Commercial Label Products installs Xeikon 3300

Cheshire, UK-based converter Commercial Label Products has installed a Xeikon 3300 digital label press.

Commercial Label Products prints self-adhesive labels in up to eight colors and provides a wide range of finishing capabilities, including lamination, varnishing, foil blocking and embossing.

Nigel Painton, managing director of Commercial Label Products, said: ‘All of the current equipment on the market has its strengths. By adding Xeikon we have recognized the continuing improvements being made by the manufacturer of this equipment. It offers a number of benefits: the ability to produce an excellent solid white is certainly very impressive; as is the fact that the machine doesn't slow down when adding extra colors into the mix. There are also no complications when running multiple sorts, which is a great productivity boost when short run is the order of the day.’ Painton cites as a further advantage the food safety standards provided by Xeikon production equipment, with toner compliant with FDA regulations related to indirect food contact and direct food contact in a dry food environment.

The Xeikon press now sits alongside the company's existing liquid toner and inkjet equipment. Commercial Label Products moved into digital production five years ago and has invested over GBP £1.2 million into new technology during this period. The company now offers the three main different types of digital label printing: dry toner, liquid toner and inkjet.

‘Different jobs suit different technologies,’ confirmed Nigel Painton. ‘We believe that we are unique, and probably a “world first” in having these three digital processes all under one roof.’

The modern suite of digital machinery sits alongside traditional label production equipment such as flexographic, foil blocking and semi-rotary letterpress. ‘Each technology has its place in the market,’ continued Painton. ‘It is common for more than one technology to be employed on our label orders. Our foil blocking machinery, for example, is busier now than ever before, foiling, embossing and die-cutting digitally printed labels.’

The Xeikon 3300 web-based press has a top speed of 19.2 meters of label production per minute. The five-color engine provides for the four standard process colors plus a choice of spot color, special security toner for anti-counterfeiting applications, or a one-pass opaque white for the ‘no label’ look on transparent material. The press is capable of handling a wide range of substrates including self-adhesive labelstocks, paper, transparent and opaque foils and paperboard. The press handles a substrate width of 330mm, and provides for an imaging width of 322mm. The environmentally friendly dry toner electrophotography imaging process enables the use of conventional substrates without the need for coating or pre-treatment.

For job preparation, the Xeikon press is equipped with the modular X-800 Digital Front-End (DFE), combining pre-press functionality including a high-speed RIP with variable data printing processing. In addition, the X-800 DFE is designed to deliver high print quality, a practical die marker function and precise step-and-repeat functionality. The system is also equipped to handle complex operations such as sequential numbering and barcodes.

Pictured l-r: Greg Neesham, Xeikon UK, and Nigel Painton, Commercial Label Products

Click here for more stories about Xeikon on L&L.com.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.