Meteor Inkjet unveils Nozzle Health Technology

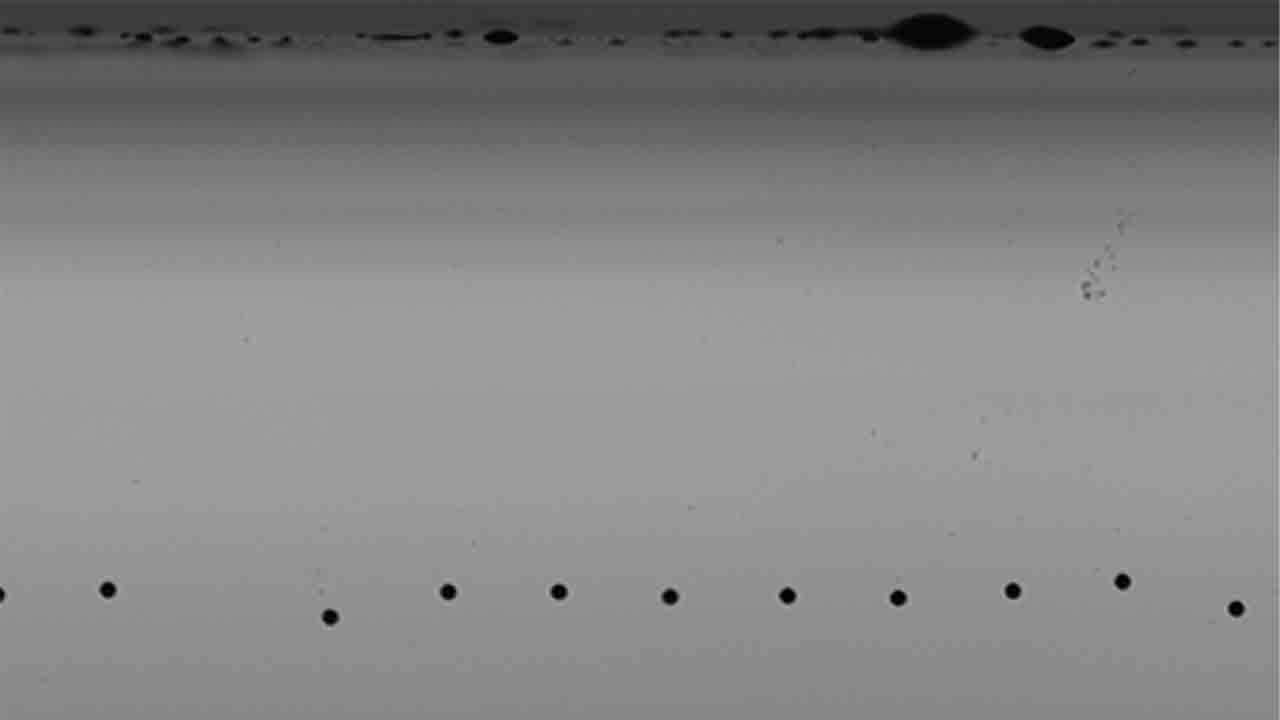

Meteor’s Nozzle Health Technology provides real-time health monitoring of every nozzle in an inkjet printhead.

Meteor Inkjet, a supplier of industrial inkjet printhead driving products, has launched its Nozzle Health Technology, the first commercially available system to provide real-time health monitoring of every nozzle in an inkjet printhead.

The technology improves the visibility of nozzle performance, giving manufacturers the ability to cut waste, reduce downtime and maintain maximum productivity.

The system measures the impulse response of each nozzle in fractions of a millisecond, instantly identifying issues such as wetting, blockage or air ingestion. Users can automatically compensate for missing nozzles using Meteor’s NozzleFix software or pause production for targeted maintenance before problems occur.

Meteor’s Nozzle Health Technology offers reliability and quality control for all inkjet applications, particularly in environments where the cost of failure is significant. Without Meteor’s Nozzle Health Technology nozzle faults are noticed only after producing perceptible errors. With this technology the nozzles can be checked without producing any faulty print.

In the packaging sector, the technology supports high-speed production of barcodes, QR codes and variable data, where even small nozzle defects can render codes unreadable and cause batch rejection or supply-chain disruption. Meteor’s ability to monitor nozzle health at the source acts as a proactive safety net. Manufacturers can run production lines at maximum capacity while knowing that every mark on every package is being monitored for integrity.

When inkjet technology is being used as the primary decoration technology, each different image typically has a different ability to hide missing nozzles resulting in frequent unpleasant surprises when switching from one job (that hides faults well) to another (that doesn’t) wasting production time and media. Meteor’s Nozzle Health Technology will enable the true status of nozzles to be known and targeted remedial action to be taken before each new print job begins.

In additive manufacturing and 3D printing, a single faulty nozzle can cause surface defects and expensive product failure. By identifying issues, Meteor’s technology ensures that uneven material deposition does not weaken layer bonding or result in fragile parts that fail under stress. In the printed electronics industry, Meteor’s Nozzle Health Technology will decrease the failure rate of any inkjet production process because remedial actions will be taken before any product is wasted.

Clive Ayling, Meteor’s managing director commented: ‘This innovation turns nozzle reliability from a hidden risk into a controlled, measurable parameter. It represents a fundamental step forward in how inkjet systems are operated, maintained, and trusted in production environments. Manufacturers face constant pressure to keep production lines running smoothly while minimizing waste. Our technology gives them the clarity they need to operate more efficiently, stay ahead of maintenance issues, and achieve consistently high print quality.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.