Leissing and Bobst introduce world's first large format foil stamping machine

- Foil stamping machine features platen with a stamping force of 600t, and can handle variety of substrates

- Allows Leissing to finish large format jobs in single pass, and has attracted interest from printers and converters

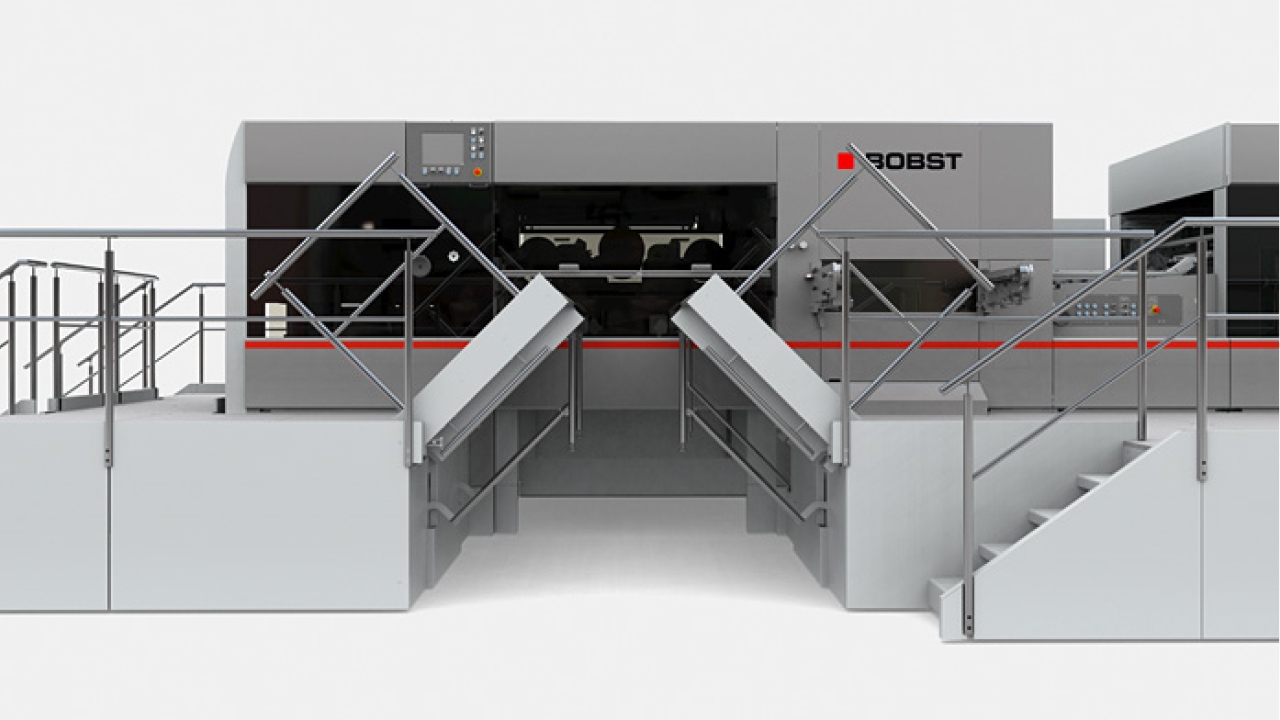

Print finisher Leissing Druckveredelung GmbH & Co. KG has started working with a Bobst Expertfoil 142, giving its customers access to the world's first foil stamping machine for the 1,420 x 1,020mm format.

The Expertfoil 142 has been developed through to market readiness in a close, partnership-based cooperation between Leissing and Bobst, after the print finishing company's managing director, Norbert Schulz, informed Bobst of his wish to install a foil stamping machine for large format operations.

A whole range of special requirements formulated by the print finisher have been taken into account, such as easy-access operability, including its walk-in foil section.

In addition, the machine incorporates a number of innovative approaches to set-up operations.

The Expertfoil 142 also boasts other strengths, such as its extremely high stamping pressure of 600t (6.0MN) and its production speed of 5,000sph, which, combined with the large format, ensures productivity.

It is versatile enough to process a wide range of printing stock – from paper with a grammage of 100g/sq m through to solid board weighing up to 2,000g/sq m, and on to corrugated board up to a thickness of 2mm.

After ordering the machine from Bobst in early 2012, the machine has now been installed at Leissing's headquarters in Landau in the German Palatinate.

The Expertfoil 142 was tested at Leissing during November and the first trial jobs passed through the machine flawlessly.

At the start of December, the first jobs produced using the new large format foil stamping machine were delivered to customers.

Schulz said: ‘Installation ran on schedule and as smooth as clockwork. Now it's in position and is a real eye-catcher.’

Leissing and its demanding customers, which include brand manufacturers in the confectionery, cosmetics, pharmaceuticals and tobacco industries, appreciate the economic advantages of the Expertfoil 142, including a high level of energy efficiency as it works with a sheet format that is twice as big as that employed by the largest foil stamping machines previously available, and its ability to make jobs with tightly costed margins economically viable.

The new foil stamping machine also allows Leissing to finish many large format printed products in a single step.

Schulz added (pictured, second from left): ‘From now on we can perform all our work in 1,420 x 1,020mm format.

Schulz added (pictured, second from left): ‘From now on we can perform all our work in 1,420 x 1,020mm format.

‘It makes little sense to print and die-cut in 1,420 x 1,020mm format if we subsequently have to surrender the advantages of this format and scale down to format 3B during the finishing stage.

‘The number of enquiries from the market is increasing. And what is more, these are coming from new customers.

‘By successfully completing this demanding project, BOBST has once again shown itself to be an exceptionally reliable and professional partner. In some ways, the Expertfoil 142 represents the crowning achievement of our partnership which goes back more than 10 years.’

Pictured, from left to right: Leissing plant manager Klaus Duda, Schulz and Volker Claus and Christophe De Gaillande from Bobst.

Read more on Bobst here

Read more about finishing and converting systems here

Read more news from across Europe here

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.