Intercoat invests in sustainability

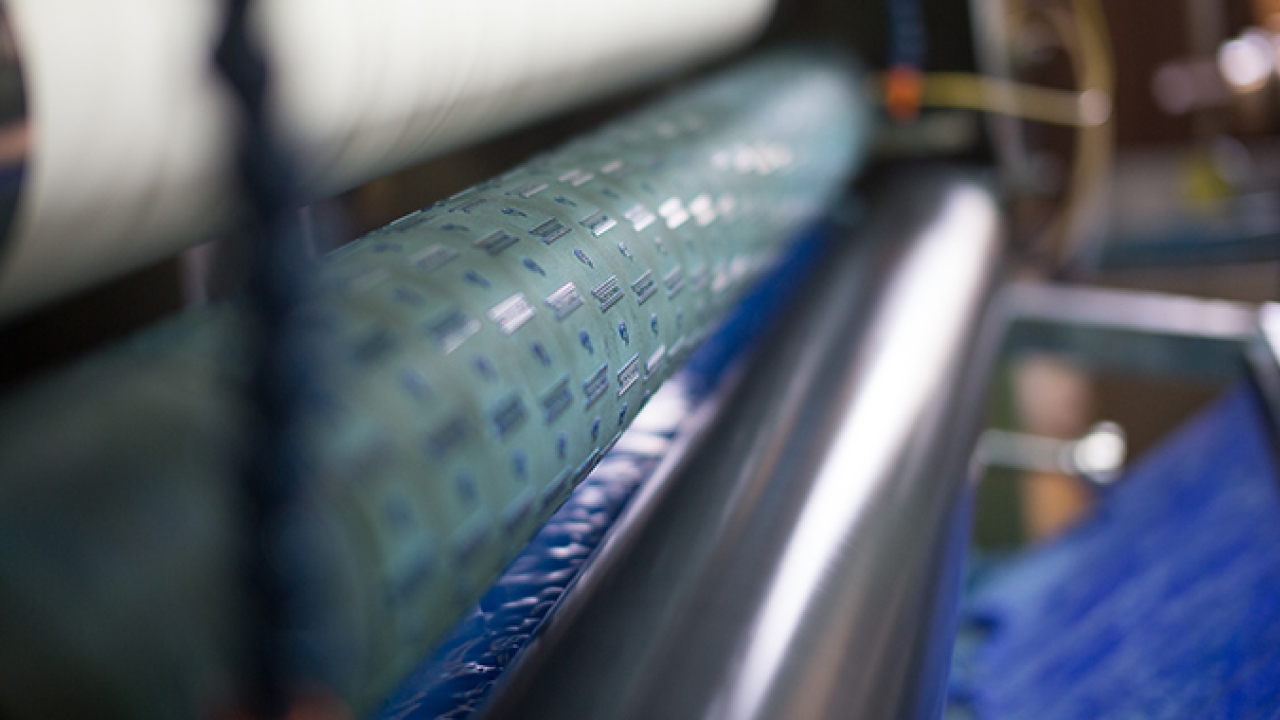

Intercoat, a German manufacturer of self-adhesive laminates for the printing, advertising, and label industries, has doubled its production capacity while reducing the environmental impact.

The company invested in a new coating machine with a working width of up to 2,150 mm, installed in 2020. The in-line process and compact design of the latest equipment enable optimal resource usage with shorter production runs and a minimal amount of waste.

‘In addition, the logistics have been optimized. Internally, Intercoat relies on short distances within the production for loading and unloading along with material handling without the use of forklifts. The company will build two new glue tank systems with automatic tank cleaning for extra efficiencies of the process. This also reduces waste of the adhesive due to unnecessary transport routes,’ said the company in a statement.

Intercoat modified and upgraded additional coating machine with minimal piping, optimized connection, and dimensioning specifically tailored to the technology of the curtain coater. Further investment in an innovative glue tank system is also planned for later this year.

The coating specialist has further minimized its carbon footprint with the installation of a 4500 sqm photovoltaic system producing 120,000 kWh of electricity per year. A cogeneration unit at the company premises supplies the new coating plant with electricity and can send the excess energy to the local power grid. Moreover, the waste heat of the cogeneration unit is used for the dryers and all coating machines. Due to the combined heat and power system, the drying gas consumption has reduced considerably with the excess heat stored in water tanks.

Later in 2021, Intercoat is planning to install an energy-efficient water cooling system in line with its sustainability efforts.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.