Xeikon releases migration white paper

In Xeikon’s newest whitepaper, Lode Deprez, vice president of technology, has provided insight into the criteria that should be taken into account when purchasing a digital printing system.

According to Xeikon, the migration behavior of digital ink systems plays a decisive role in the selection of a digital press and determines to a large extent which application segments the printing system can cover.

The white paper addresses the question of why there can’t be a ‘one ink’ system that is suitable for all applications in digital packaging printing. It outlines the complex requirements for ink systems, which differ in their migration behavior and whose food safety properties are a key criteria when selecting a machine system.

The white paper provides a brief overview of the key regulations issued by legislative bodies, associations and branded goods manufacturers, and provides easy-to-understand information on the current migration limits.

Additionally, the white paper discusses the importance of the chemical composition of digital ink systems on migration behavior. By looking into the different composition of dry and liquid toner and UV inkjet inks, it highlights the advantages of the respective ink systems for different applications.The transfer from printing inks to food depends on other factors such as storage time, storage temperature, barrier properties of the packaging material and, ultimately, the packaged good itself is also discussed in the report.

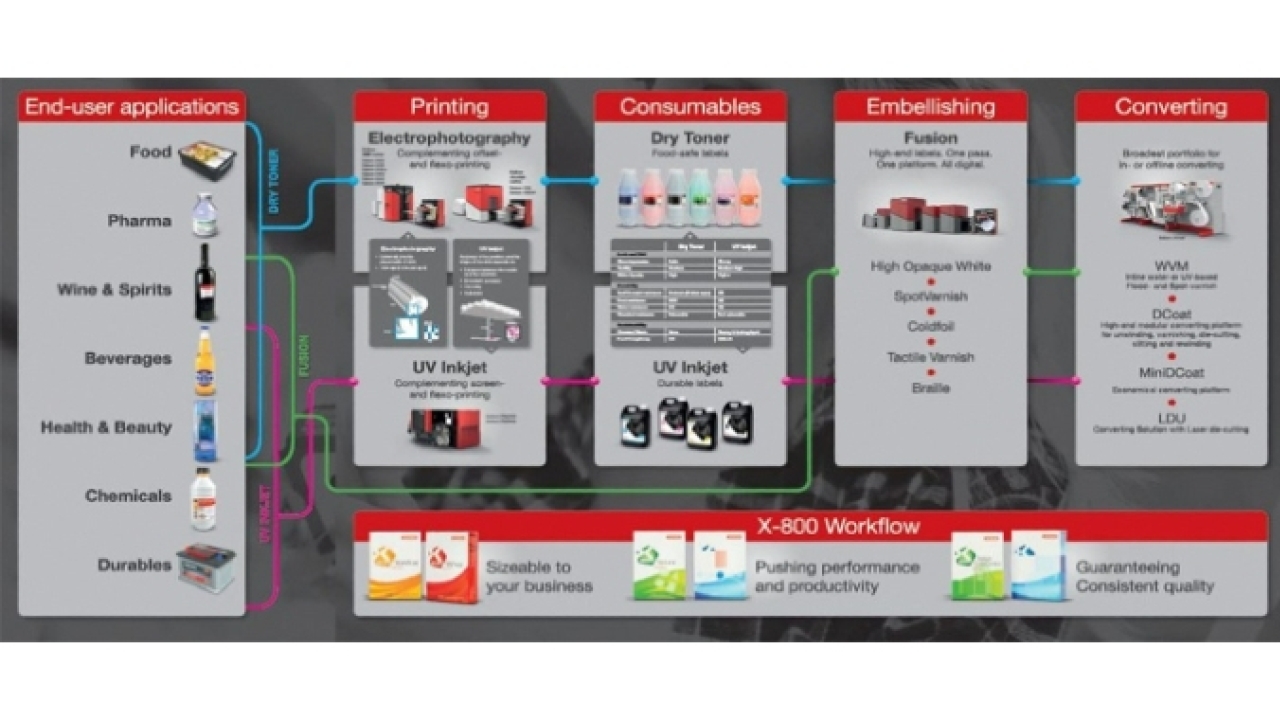

Divided into the segments of food, pharmaceuticals, wine & spirits, beverages, health & beauty, chemicals and consumer goods, Xeikon claims that individual recommendations can be derived for each label and packaging printer depending on the composition of their portfolio, which will help them when deciding on a digital printing system.

You can download the White Paper here: https://go.xeikon.com/wp-lowmigration_en

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.