Zecher expands production capacity

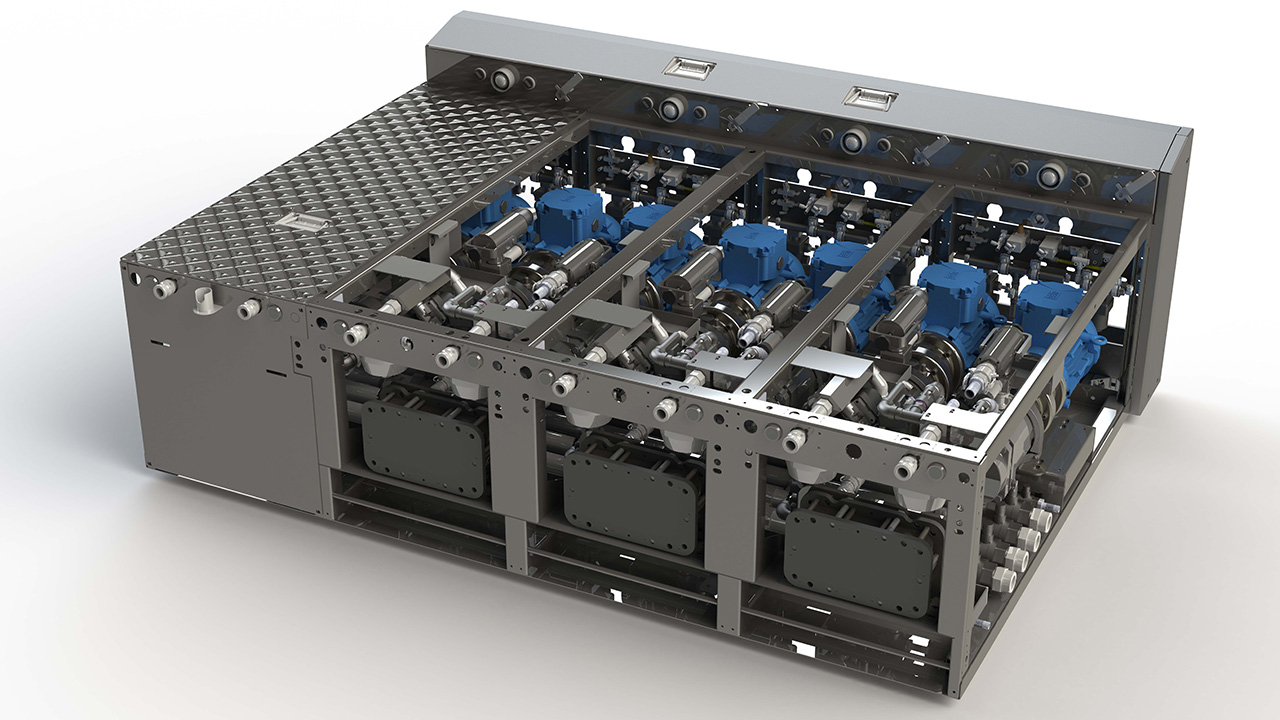

Zecher, a global manufacturer of anilox rollers, has expanded its production capacity by 25 percent by acquiring an additional ceramic coating machine.

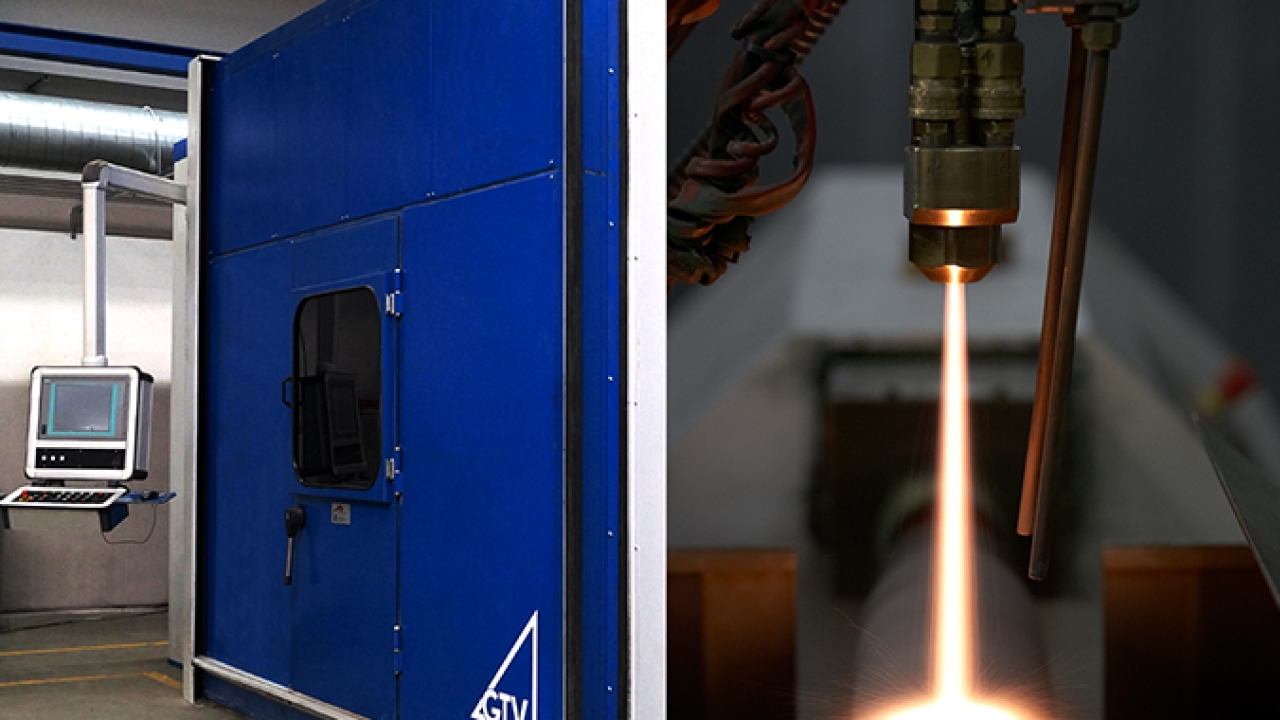

To meet the requirements for a functional coating, highly resistant to abrasion and corrosion and suitable for high-resolution laser engraving up to 700 L/cm, Zecher relies on plasma coating technology. It enables the required functional layers to be manufactured with qualitatively convincing mechanical properties as well as residual porosities of less than 1 percent.

The applied functional layer forms the basis for engraving the anilox rollers and sleeves. The established and high-quality chromium oxide ceramics (Cr2O3) are characterized by good melting behavior and high density. The nature of the ceramic coating determines the precision, the printing properties, and the long-term performance of the ceramic rollers.

‘With the supplementary acquisition, we are responding to the increasing demand on the world market for Zecher products and are also more flexible in the area of individual coatings for rotationally symmetrical components,’ commented Rüdiger Wand, managing director of Zecher. ‘Our customers, and thus also we, are so satisfied with our most recently acquired thermal coating system and the performance it has achieved that the acquisition of a further system with this technology was an obvious choice.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.