Alu-Lids purchases first MPS flexo press

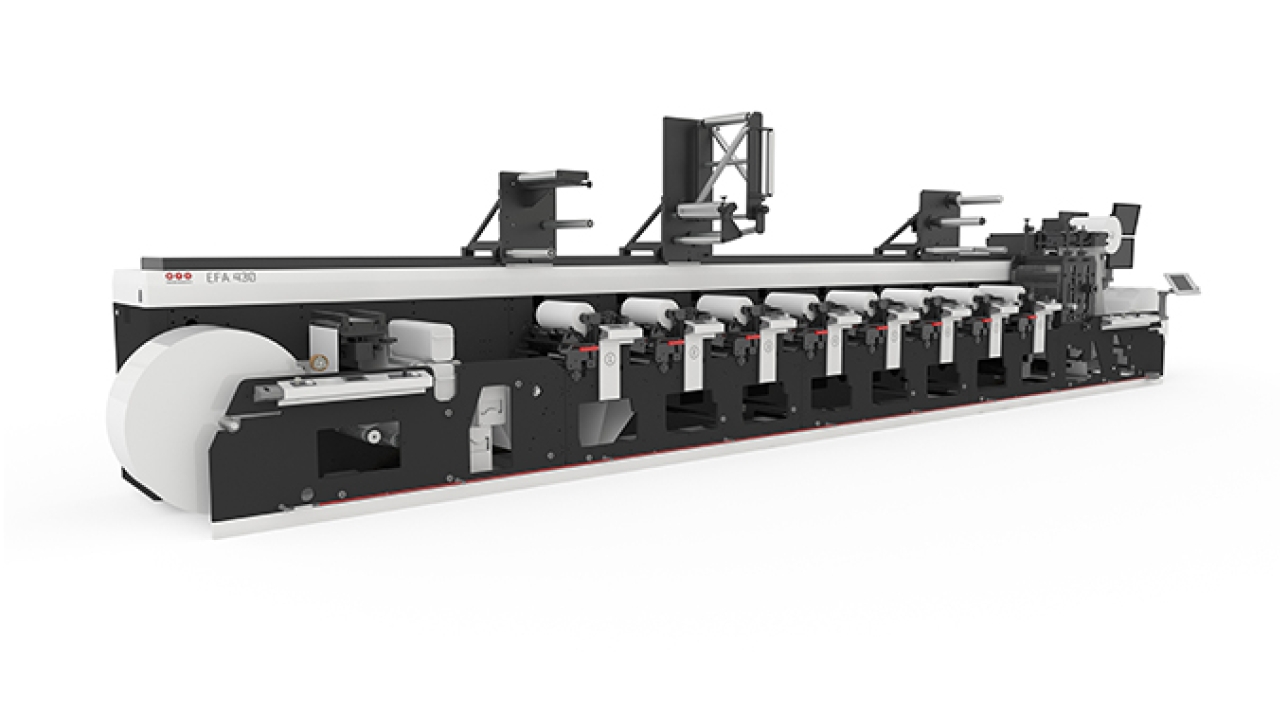

Alu-Lids, one of the leading providers of aluminum lids for cosmetic companies in Poland, has purchased a fully automated MPS EFA 430 flexo press to increase its production capacity, turnaround time, and quality control.

Alu-Lids started operating in the packaging industry in Wrocław in 2001. Two years later, in 2003 the company began producing aluminum covers, specializing in the cosmetics industry.

Together with MPS’ new representative Reprograf-Grafikus in Poland, MPS regional sales director, Anton Zhukov presented Alu-Lids the features of the EFA 430 flexo press that could elevate its production, such as special aluminum packaging, very stable register and second pass printing for finishing effects, in addition to benefits of the MPS Performance Program. Due to travel restrictions from the Covid-19 pandemic, Alu-Lids confirmed the sale over the telephone.

‘We are a one-stop service,’ said Dawid Kamiński, CEO of Alu-Lids. ‘To guarantee shorter lead times, faster delivery, and better-quality control, a high-end printing press was essential. The MPS flexo press was the best choice as an addition to our production plant to increase capacity.’

Alu-Lids was also looking to partner with a service-focused supplier to guide the project before and after press installation.

‘By owning an MPS press with its Performance Program, the control, monitoring, management, and improvement of printing production is in our hands, with ongoing support from MPS,’ added Kamiński. ‘With the MPS patented technologies, we will experience higher productivity and efficiency with less commissioning and reduced risks. We are excited about installing our new MPS press and the benefits it will bring to our production.’

‘With 25 years of experience in the label printing industry, MPS truly understands our customers’ needs and what they are facing. We bring tremendous value with the MPS Performance Program by ensuring our customers are supported before and after equipment installation,’ commented Zhukov. ‘The MPS Performance Program transforms our customer’s press into a printer’s equivalent of a Formula One mission control room, providing exact details to improve the overall print operation. All of this leads to higher productivity and profit.’

‘It is not always easy to improve the supply chain, especially with the consistent print quality and on-time delivery,’ added Tomasz Naglik, product manager at Reprograf-Grafikus. ‘MPS flexo presses meet these criteria. Each MPS press can print with consistent quality on all repeat and similar jobs and can produce larger quantities of labels in a shorter period while running at extremely high speeds. This helps the customer run more jobs and increase revenue. We sincerely hope that, just like Alu-Lids, other prospects will also see and take advantage of value propositions offered by MPS.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.