Seikodo adds CrystalCleanConnect

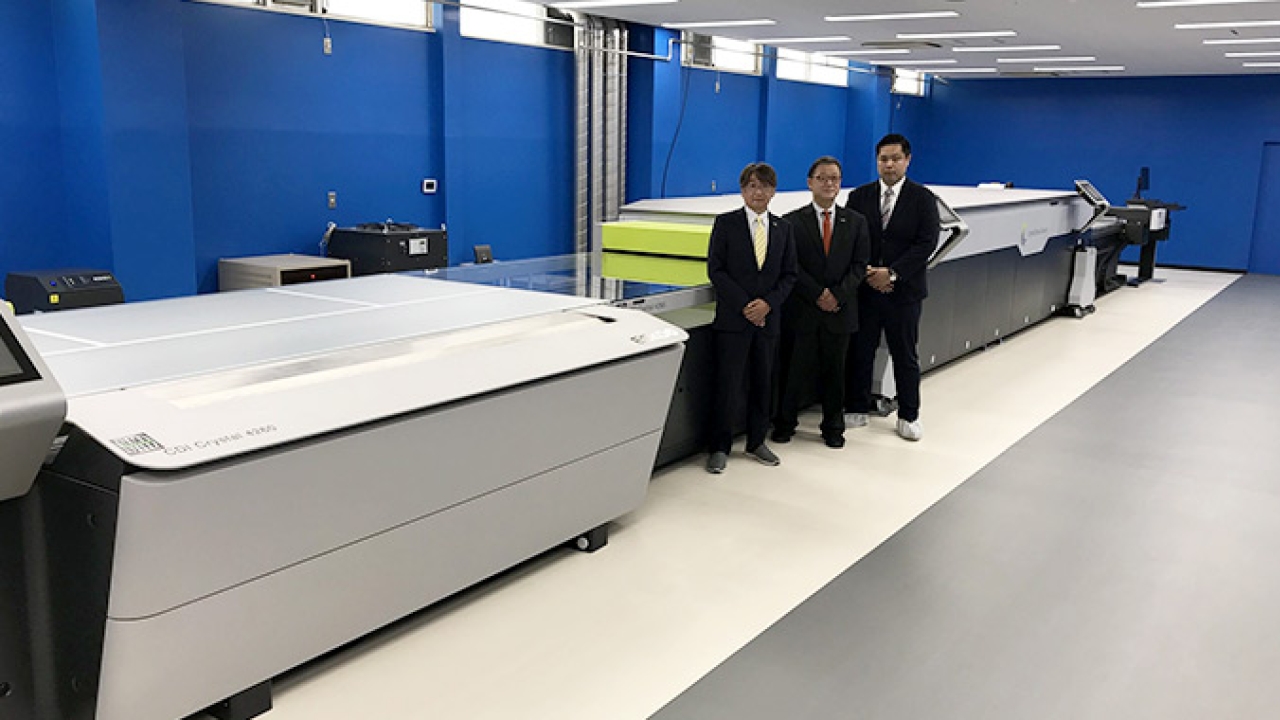

Japanese Seikodo Corporation has installed Asahi Photoproducts CrystalCleanConnect, a fully automated flexo platemaking system to boost its productivity, sustainability and protect the health and safety of its employees.

Seikodo Corporation was formed in 1959 and is one of the experts in helping trade customers create artwork suited for flexographic printing and preparing it for print to achieve the best possible printed quality.

‘Before implementing CrystalCleanConnect, we were using solvent-wash plates,’ said Kaneko Osamu, chief procurement and technology officer at Seikodo Corporation. ‘We were looking for a better solution that would improve our sustainability, contribute to our goal of carbon neutrality, and improve our work environment. We were pleased to learn about CrystalCleanConnect, which met all those requirements and more.’

According to Osamu, in addition to its initial goals, the company was able to transition from solvent-wash plates to Asahi’s AWP CleanPrint water-washable plates while improving the overall quality of the plates it was producing, introducing improved production efficiency, and reducing both cost and waste.

‘By introducing CrystalCleanConnect, a fully automated system, we can find a solution to the less skilled labor market and missing young talent in our industry. CrystalCleanConnect represents, due to its level of automation, an important solution to maintain high-quality platemaking output. All of this adds up to positioning flexography very competitively with offset and gravure for packaging printing,’ added Osamu.

CrystalCleanConnect is a clean and sustainable process with no VOC-based washout solvents due to the use of Asahi’s AWPT CleanPrint water-washable plates, with high levels of automation generating a cut plate ready for mounting.

According to Asahi, CleanPrint technology ensures a significant OEE improvement, up to 40 percent. The ink usage can be reduced by around 20 percent due to Crystal Screening technologies. Key to the CleanPrint technology is the fact that plates are designed to release ink, resulting in few, if any, press stops for plate cleaning, keeping a consistent print quality from beginning to end of the run. The close nesting of digital files enables precise plate cutting by the Kongsberg table and results in an additional 10 percent plate waste reduction.

The name CrystalCleanConnect derives from the Esko Crystal and Asahi CleanPrint product branding with the philosophy of connecting the printing form making value chain from design to print as one integrated workflow.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.