Shanghai Huichang Flexo installs AWP CleanPrint platemaking system

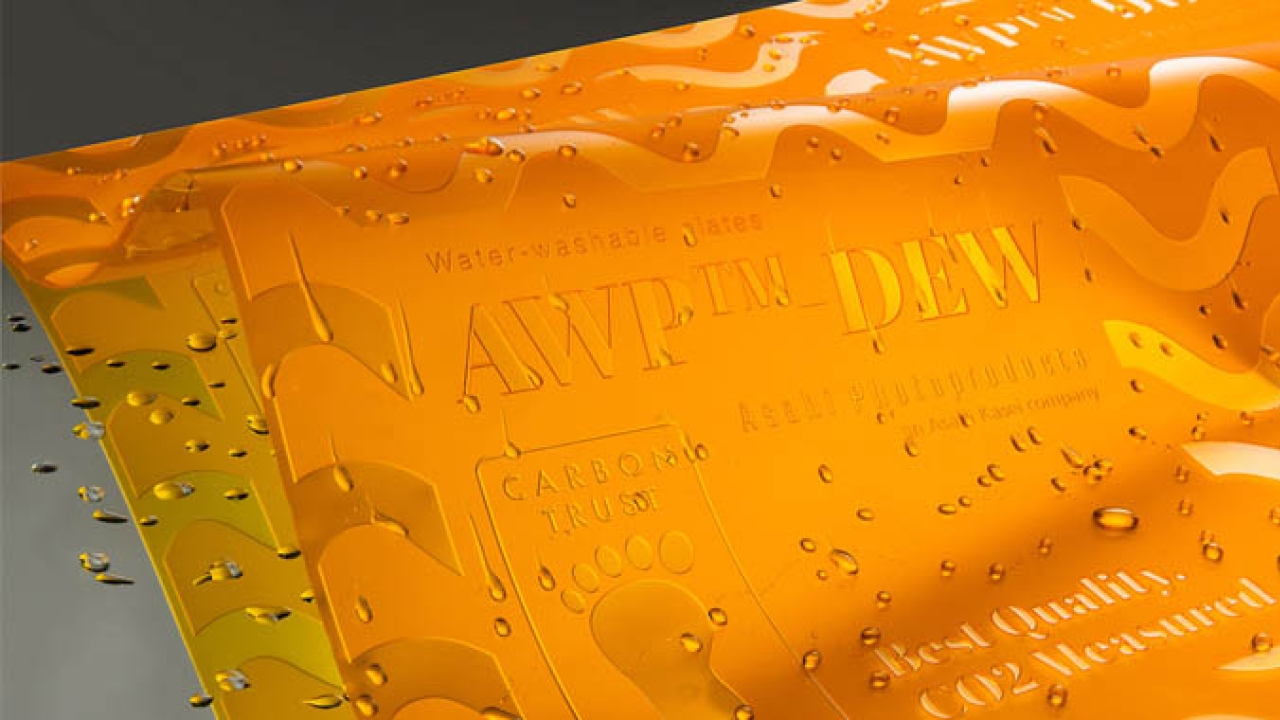

Repro house in Shanghai, China, Shanghai Huichang Flexo Technology has installed Asahi's AWP CleanPrint water-wash platemaking system, a processor capable of producing flexographic plates up to 1067x1524mm (42x60 inches).

The AWP water-wash processor works with an eco-balanced plate that doesn’t use VOC-based washout solvents in the platemaking process and is claimed to emit less carbon dioxide than alternative systems.

Shanghai Huichang Flexo Technology is a newly established company founded in 2021. The company was looking to introduce an efficient and eco-balanced plate to support long-term business development in China, in harmony with the environment. The company opted for the Asahi Kasei AWP CleanPrint water-wash platemaking processor that was installed on its site in August 2021.

Huichang Flexo has been operating the system for several months and is satisfied with its ability to deliver excellent plate quality with a reduced carbon footprint, an increasingly important benefit as demand for sustainable solutions continues to grow in China, according to Asahi.

In addition, the AWP water-wash system features Asahi Kasei's proprietary CleanPrint technology. This feature is said to enhance ink transfer from the plate surface to the printed substrate and reduce ink filling.

Pinghui Ren, president of Shanghai Huichang Flexo Technology, said: ‘We introduced platemaking equipment to the Chinese market, including the Asahi Kasei's AWP CleanPrint water-wash platemaking system, to provide flexo printing companies with high-quality plates in balance with the environment. In China, environmental regulations are becoming more strict, and many companies need to take urgent action to be compliant. To assist them, we introduced a platemaking system that can produce water-wash plates up to 1067x1524mm with a water-wash solution. These plates deliver high-quality print in harmony with the environment for companies that print on various substrates, including paper and flexible packaging material, and we highly recommend them.’

Toshiki Sugawara, sales representative for Asahi Kasei Electronic Materials (Changshu), added: ‘Asahi Kasei's AWP CleanPrint water-wash platemaking system has proven highly effective for the production of high-definition applications around the world. In the future, flexographic printing, which has a low environmental impact, will primarily be used for flexible packaging in China because of the easy conversion of packaging from gravure to flexo printing. We are very excited to support this transition in China with our AWP platemaking solution and its many benefits, such as the improvement of printing efficiency and the low environmental impact.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.