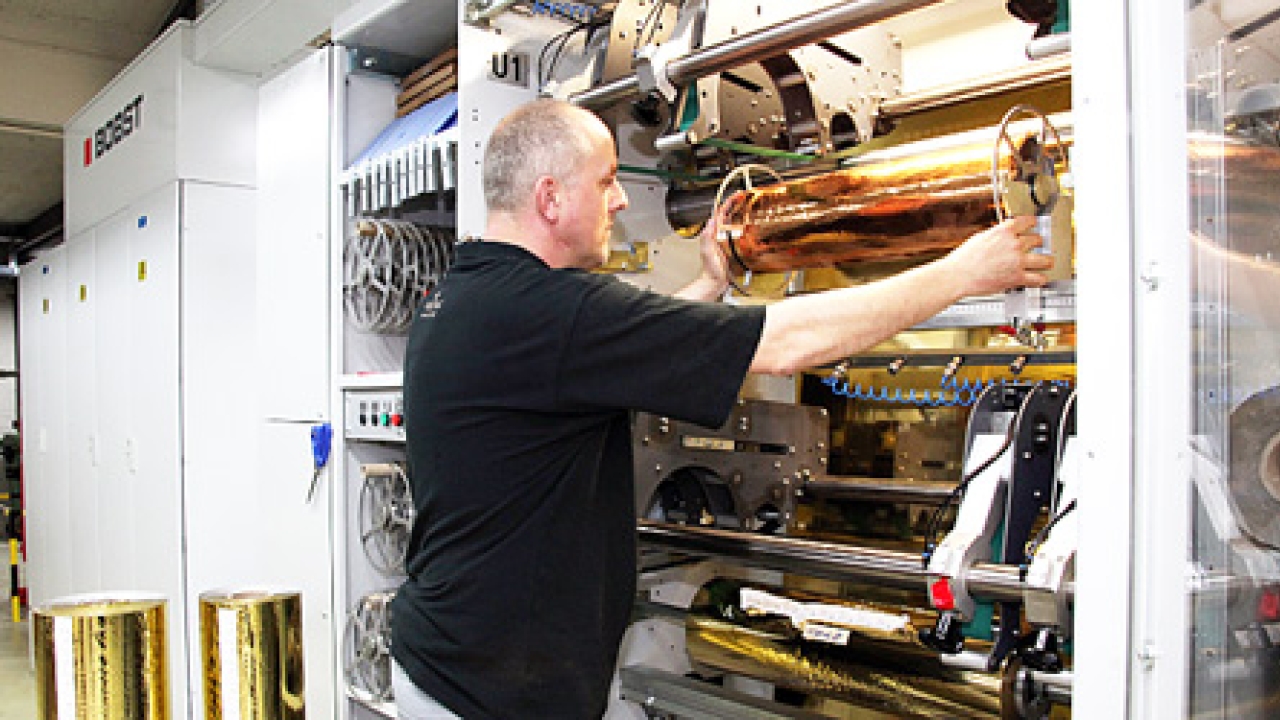

Vrijdag installs Bobst Masterfoil 106 PR

Vrijdag Premium Printing has installed a Bobst Masterfoil 106 PR as part of a ‘larger plan’ to enhance its capabilities and offering, and respond to growing demand for foil.

Vrijdag Premium Printing produces labels and packaging for many well-known brands all over the world. With tobacco packaging as a key market, it supplies manufacturers of machine-made cigars in Europe and the USA, along with the many hand-rolled cigar suppliers in the Caribbean. Other important markets for the company include spirits, confectionery and high-end gift packaging.

Bobst’s Masterfoil 106 PR is a hot foil stamping press with a running speed of 8,000sph, and is able to handle substrates from 70gsm paper up to 2,000 gsm cartonboard.

The press also utilizes Foil Touch, which revolves around a completely rethought platen concept and a redesigned lower beam movement system, and which Bobst said creates better foiling quality at high speeds with lower heat and pressure requirements.

A longer dwell time also means that some jobs, which on the older equipment required two runs – one to foil and one to emboss – can now be produced in a single run.

In addition, the Power Register II system on the Masterfoil ensures highly accurate foil to print registration on every sheet by using high-speed cameras and powerful real-time data processing.

Henk Nota, Vrijdag Premium Printing managing director, said: ‘Before this investment we had older machines with lower speeds. We could see an increase in business as regards foil, so we were at a crossroads where we had to decide to invest in more people and to run the machines longer every day, or to install newer, more efficient equipment that would also push quality forward.

‘The long history of Vrijdag gives us knowledge and stability, but this new machine is part of our future and it is a future of innovation and efficiency. This implementation is part of a larger plan.

‘We are a company that is investing in speed, investing in reliability and efficiency, and investing in the best available equipment, while also capitalizing on a heritage which gives us the confidence to take from the past those things that have been shown to be successful,’ Nota concluded.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.