Western Concord Manufacturing makes major inspection investment

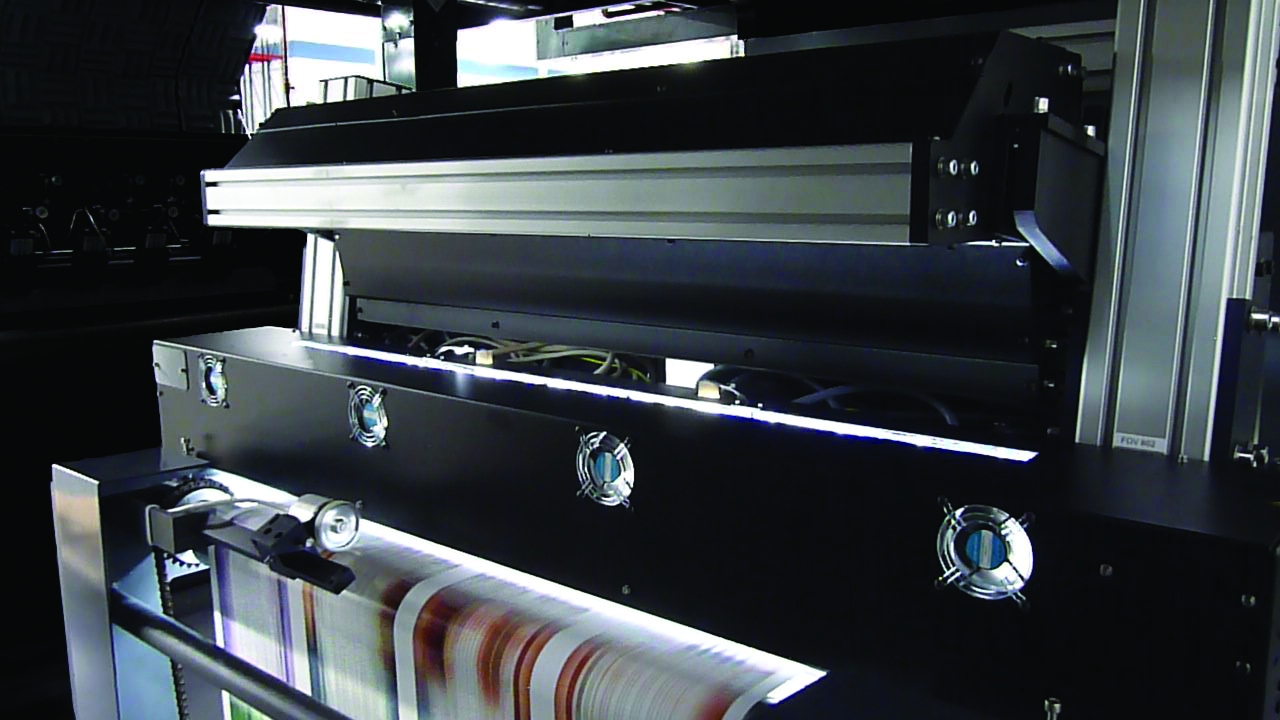

Western Concord Manufacturing has partnered with AVT to utilize its Argus Turbo 100 percent print inspection system on each of its 10-color printing presses across its operation in Vancouver, Canada.

AVT’s Argus Turbo features two advanced sensing technologies that afford 100 percent inspection of the web at high speeds while, in tandem, an area-based camera zooms in to inspect various locations of interest at high-resolution. To guarantee consistent print quality, the system visually inspects all types of print defects, including color variations, mis-registration, streaks, splashes, misprints and more.

Argus Turbo visually indicates the position and type of defect, and can inspect all types of printed materials, including transparent flexible substrates, identifying random and process print problems before they result in waste and customer rejection.

Western Concord Manufacturing, which is headquartered in Vancouver, said the investment shows its commitment to continuously improving quality and performance for customers in the consumer flexible packaging, industrial packaging and construction film sectors.

Western Concord Manufacturing president and chief executive officer Peter Tyszewicz said: ‘[We have] a legacy spanning more than 30 years of being the best flexo printer on the West Coast.

‘The Argus Turbo allows Western Concord Manufacturing to inspect 100 percent of print quality, and also accurately measure good impression counts, thereby improving the quality and consistency of our packaging for our customers and better serve our customers’ supply chain needs when it comes to packaging.’

James Davidson, vice-president of sales, marketing and product development at Western Concord Manufacturing, added: ‘We are very excited about the value that this investment brings to our customers.

‘We can now integrate quality using digital systems that allow us to take jobs from prepress to print to converting operations while greatly improving our accuracy in other aspects, such as order quantities. This investment enables us to greatly improve quality and consistency, reduce lead times, and increase overall service.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.