Zincografia improves sustainability with Asahi equipment

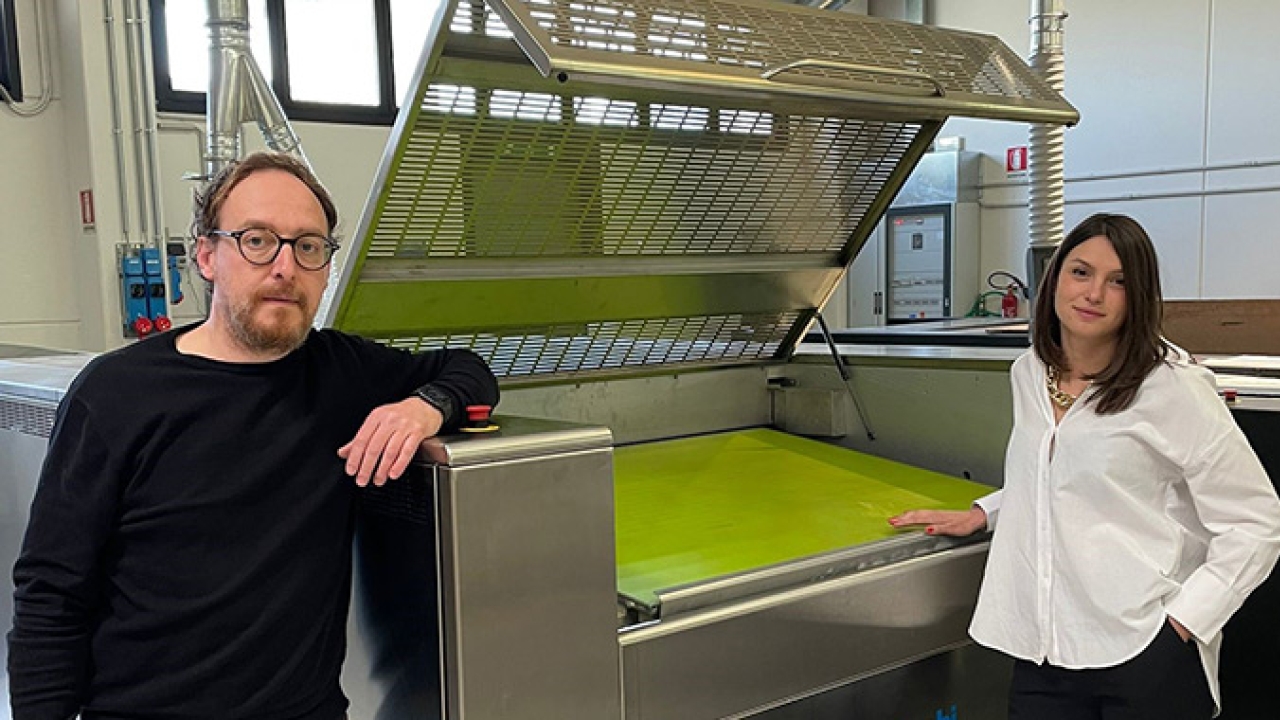

Italian repro house Zincografia Empolese has invested in an Asahi AWP 4835 P flexo plate processor and Asahi AWP-DEW CleanPrint water-washable plates for its production facility in San Miniato.

The company, founded in 1985, is a business unit of ZE Group, providing flexo plates for customers in a wide range of markets, including labels, flexible and corrugated packaging.

‘Before acquiring our Asahi plate processor using AWP-DEW CleanPrint plates, we used various products,’ said Noemi Bisoli, managing partner of Zincografia Empolese. ‘We made the switch for several reasons, including the excellent support we get from Asahi, the faster processing time for plates in prepress, and the reduced downtime in the press room for plate changes or press stops for plate cleaning at our customer sites. We also appreciate how sustainable the entire platemaking process is with Asahi AWP-DEW water-washable plates, a factor that is increasingly important to our customers.’

Bisoli noted that the company uses a significant amount of flexo plate material annually. With the new efficiencies offered by the Asahi configuration, the company expects that number to grow significantly.

Asahi AWP CleanPrint water-washable plates are processed without VOC-based washout solvents. According to the company, the production process uses less energy and delivers a faster time to press than VOC solvent-wash plates.

The water-wash technology also features a low-surface energy plate, resulting in fewer press stops for plate cleaning, significantly improved OEE in the pressroom, and reduced press waste. The manufacturer claims that all of these elements make them the most sustainable flexographic plates in the industry.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.