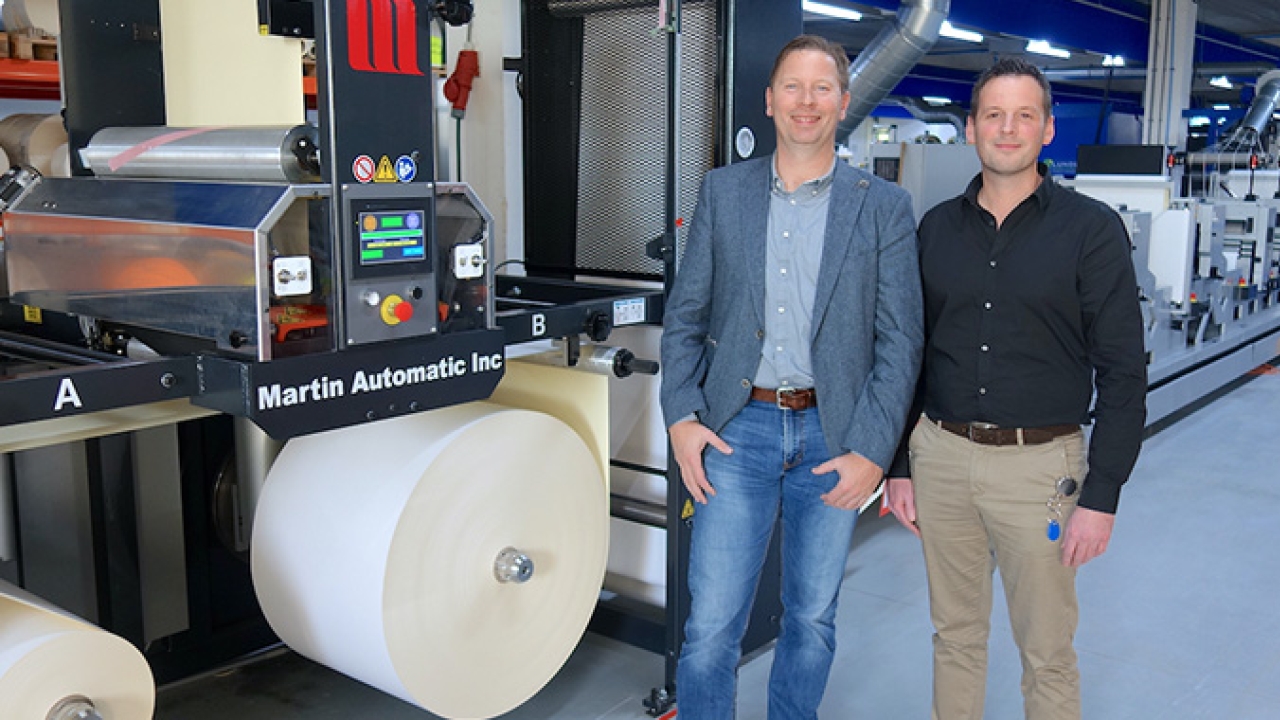

Zolemba installs Martin Automatic unwind splicer

Dutch label converter Zolemba has installed a Martin Automatic MBS unwind splicer to improve productivity and reduce its residual waste.

The MBS non-stop unit, which has been fitted to 530mm converting line with two flexo print stations and two die cutting units. According to the converter, the new equipment has made a significant difference to machine downtime for roll changes with the line typically running at 120m/min.

Zolemba first became aware of Martin Automatic technology at Labelexpo in Brussels in 2017 and the machine has been commissioned in January 2019 after a series of demonstrations that highlighted how an automatic unwind/splicer could improve productivity.

‘The MBS is working perfectly and performing as promised,’ said Marthijn Kieneker, chief production officer at Zolemba. ‘In fact, we’re achieving even better figures than we had predicted with the Martin. With up to 16 roll changes per shift and a saving of around 10 minutes on each, the numbers add up to major savings. That is not even considering the part-used rolls of different sizes that can now be utilised, and the low residual waste on each that can be achieved with automatic splicing.’

Martin Automatic MBS is capable of handling rolls up to 1016 mm (40in and offers the opportunity to splice from one roll of material to another at standstill when effecting a job change.

‘There is no doubt that non-stop is the way forward,’ added Richard Rensen, owner and CEO of Zolemba. ‘The Martin MBS has shown us how to improve productivity and the benefits it brings, which we have extended to the handling of the matrix waste with the addition of a pneumatic removal system. By removing previously unseen bottlenecks in the production process, automation acts as an accelerator. We estimate the MBS has given us more than two extra hours of production on each shift, that’s a major shift in efficiency.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.