Australian university uses adapted label press to create solar panels

University of Newcastle in New South Wales, Australia, has used an adapted label printer to create solar panels, strengthening Australia's position as a global leader in printed solar technology.

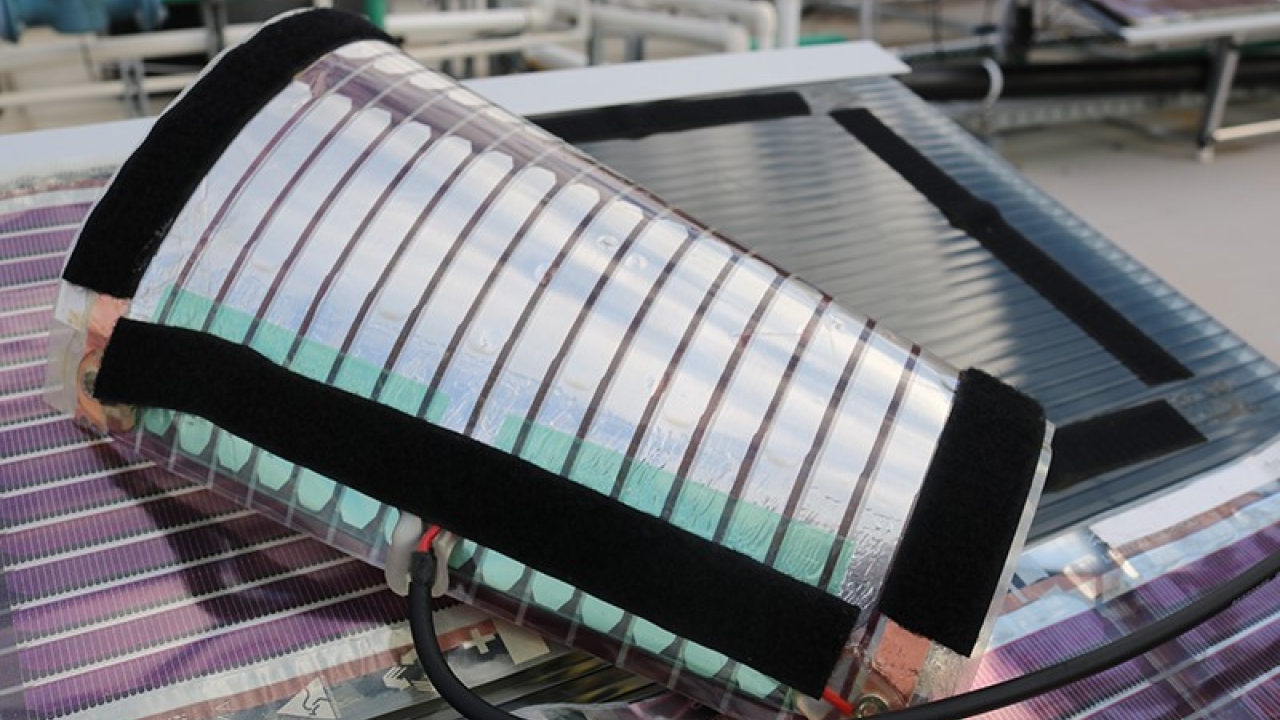

The material is made by printing an advanced electronic ink onto paper thin, clear laminated sheets using conventional label presses. Professor Paul Dastoor’s UON team pioneered both the electronic ink and printing process. ‘On the back of five years of in-house development, all of the components of these advanced electronic inks are now synthesized at scale within our Centre for Organic Electronics using non-toxic carbon-based materials,’ commented Dastoor. ‘These components are then used directly or further processed into water-based inks and paints.’

The project has strengthened Australia's position as a global leader in printed solar technology. The printed solar demonstration site at the University of Newcastle is the first in Australia. At 100 sqm in size, Dastoor said there are only two other comparable sites worldwide.

‘There are just three demonstration sites at this scale that we know of anywhere in the world, so Australia has joined an elite group of global leaders poised to make this technology a commercial reality.’

Initially, the electrical output of the site is being used for scientific study, allowing Australian researchers to monitor how large areas of these unique printed solar cells respond under different real-world conditions. Unlike traditional photovoltaic panels, it is claimed that the technology maintains a more constant power flow in low light and cloud cover.

Dastoor explained: ‘Our printed solar solution continues to function consistently in low light and under cloud cover, which means that users don’t experience dips in productivity. So sensitive, the material can even produce small quantities of energy from moonlight.’

The university's lab-scale printer can produce hundreds of meters of material per day, increasing to kilometers on a commercial-scale printer, according to Dastoor.

‘If you had just 10 of these printers operating around the clock we could print enough material to deliver power to 1,000 homes a day.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.