Labelexpo Europe 2015 new products preview - inspection

As part of L&L's comprehensive preview of new products to be seen at Labelexpo Europe 2015, here the magazine highlights new inspection tools and systems that will be seen at the show.

The full preview can be read in L&L issue 4, 2015, and online here, while you can read more about the following technologies on the L&L website: digital presses; conventional presses; inks, curing and drying; materials, adhesives and coatings; MIS and pre-press; ancillaries; finishing; linerless; and package printing.

AVT premieres the Helios S Turbo inspection system designed to help increase printing and rewinding speeds. Offline Setup is introduced, designed to standardize inspection results and address the needs for production processes automation. SolidProof is a new off-line proofing system to ensure that no critical errors have been overlooked in the print production process, with options for barcode and Braille verification, as well as a 21 CFR Part 11 compliance module for the pharmaceutical sector. Partner stands will host the ZeroSet automated inspection workflow for digital presses, while AVT will also demonstrate for the first time technologies developed with Erhardt+Leimer (E+L).

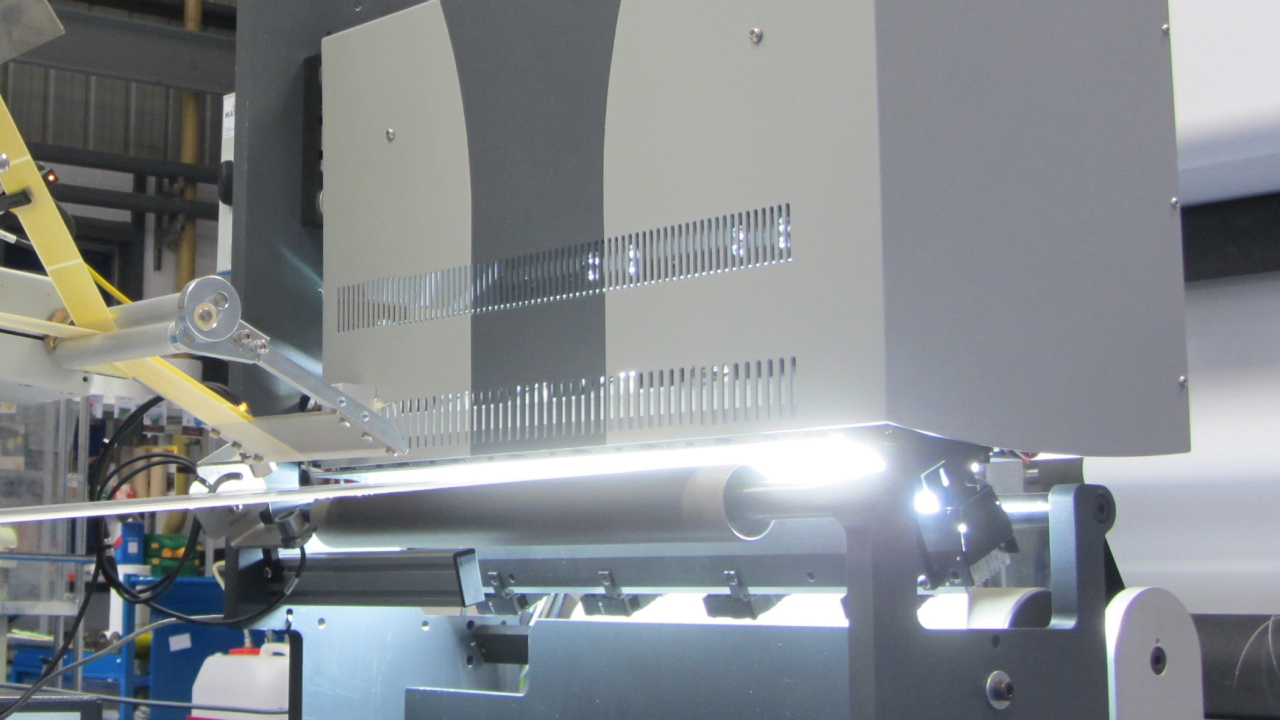

The newly developed multi-function Smartscan inspection system incorporates video function with zoom, 100 percent print image inspection, splice detection and detection of missing labels and unremoved matrix. The camera unit is housed in a compact enclosure, which means Smartscan can be retrofitted to existing printing and finishing machines.

Shows new features for its EyeC inspection system including 100 percent inspection of composite jobs. In one click, label printers can verify jobs with different labels, for instance front and back labels, against their corresponding PDFs, and for the whole production run. EyeC has also integrated new and more powerful scanners into its EyeC Proofiler range of off-line inspection systems and ProofRunner in-line inspection systems. EyeC also displays Proofiler Content, allowing operators to check changes during artwork design and revision.

Shows the Lineavision inspection system, which checks for label surface anomalies and dimensional characteristics during the manufacture of security labels. Using computer-generated templates, the software checks the degree of compliance against a pre-defined vectorized model. The recorded data enables 100 percent real-time quality control and guarantees the traceability of each label. All information is collected in a report, which maps the entire web and contains all error characteristics.

Shows the Sprint 420 quality inspection system able to inspect defects of 0.1 sq mm area at a speed of 300m/min. The LabelRoll 330+ (vertical) inspection system inspects 3D printing defects such as excessive glue and bubbles. It Inspects a defect area of 0.06 sq mm at 200m/min.

Introduces new multi-screen interface for Alis camera line allowing up to 12 apps for web-viewing, color and register measurement, trend analysis and defects to run simultaneously. New camera models offer higher inspection speeds. The entry-level M1 camera product line has been extended with 520 and 630mm wide models. The ODRI product line with print-to-PDF and PDF-to-PDF verification now offers multi-artwork support, color consistency check and optional barcode grading.

One Box Vision introduces ImageFlow, a modular vision system which can be used to proof, inspect and serialize. The package includes Image Match, used to verify what’s on the press is what is in the customers design file; Print Master, used to guarantee that no defects will be printed during the job; and Code Flow, a complete serialization system that includes an interface to the leader in cloud based EPCIS compliant repositories and brand protection.

Launches the Graphic-Vision GV-Spectro system web viewer with in-line color measurement. The GV-Spectro provides all the functionality of the GV500 series web viewers, and now also offers in-line absolute color measurement and real-time reporting. The most advanced of the Graphic-Vision 500 Series is the GV530/Spectro, which offers motorized traverse with programmed positioning and auto repeat scanning, making it easy for the operator to monitor the most important areas of interest on the web.

Introduces three new inspection systems: Espial allows the image on every label to be captured in succession for a continuous sequence, which appears like a stationary image. The major advantage of this system is the ability to use it at any speed, providing precise, visual, operator controlled label inspection. The Revelation passive video web inspection system is for wider web printing applications. I-Pro hologram inspection system is for viewing embossed holograms in real time production and can be used anywhere in production – embossing, metalizing, de-metalizing, print or rewinding. The system constantly scans the entire repeat.

Launches a portable 2D barcode verifier, the battery-powered TruCheck Rover. The Rover verifies linear (1D) barcodes and 2D matrix symbols in full accordance with industry standards, including ISO/IEC 15415, 15416 and AIM DPM (45Q illumination only). The Rover verifies ‘virtually all’ barcode and 2D symbologies including UPC/EAN, Code 128, data matrix and QR code.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.