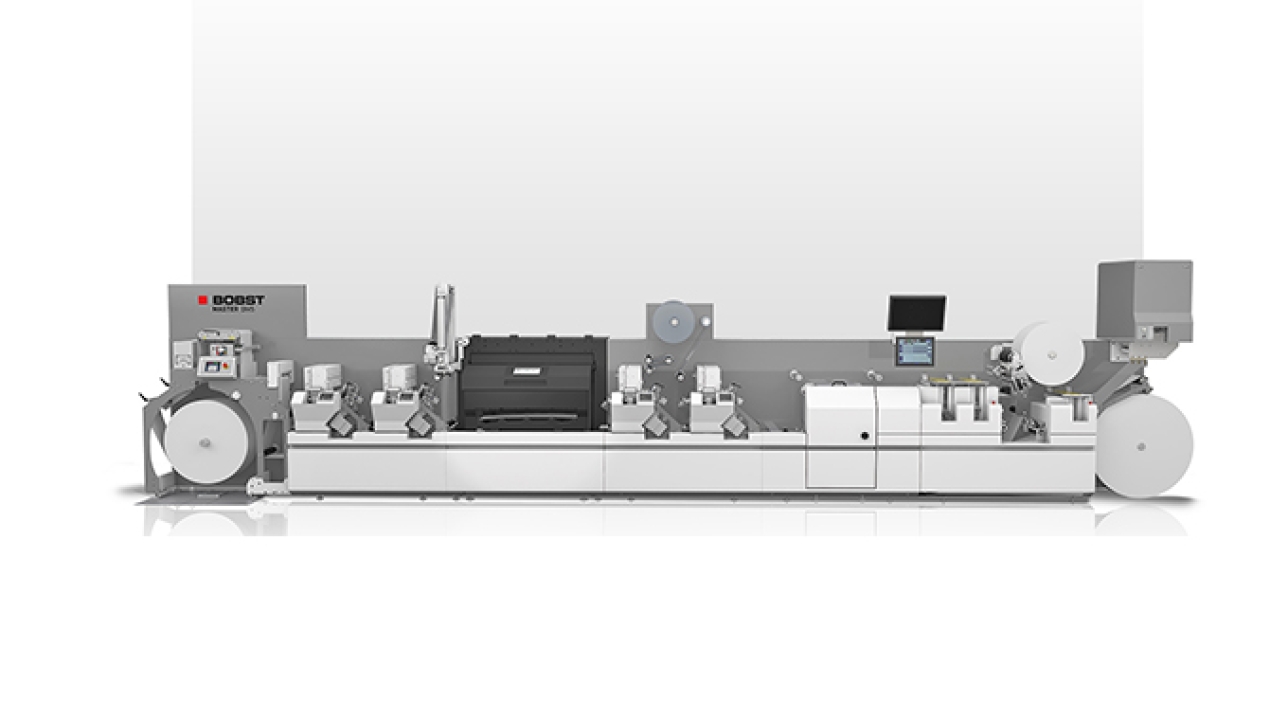

Bobst launches Master DM5 hybrid press

Bobst has launched the Master DM5 hybrid label press, which combines Mouvent inkjet technology and DigiFlexo printing in a single press.

‘The Master DM5 is our first ever fully digitally integrated hybrid press and represents a new era in the production of self-adhesive labels with totally new standards of productivity and profitability,’ said Jean-Pascal Bobst, CEO of Bobst. ‘Bobst can now offer the full range of digital, hybrid and DigiFlexo solutions, which are perfectly integrated, interchangeable and scalable to all present and future needs.’

The digital print engine inside the Master DM5 is made up of Mouvent’s proprietary Cluster Technology – integrating Fujifilm Dimatix Samba printheads – which is the basis of the entire range of digital printing machines developed by Mouvent, Bobst’s digital printing competence center. The Mouvent Cluster heads are compact and simple to change for easy and accessible maintenance, and have all-in-one fully integrated inking, conditioning and electronic circuits.

‘Two of the greatest benefits of the Master DM5 are its productivity and reliability,’ said Federico D’Annunzio, Bobst program manager hybrid printing. ‘It represents a total flexo-digital-converting integration, with non-stop productivity, and the highest press uptime in the industry. It prints at speeds of up to 100m/min at the highest quality, 1,200 x 1,200 DPI. Full digital automation means that only one press operator is needed to print high added value label jobs, in short and medium runs. Job changes on-the-fly, without stopping the press, are possible for flexo, digital, die-cutting and stripping processes. All analogue tools (print cylinders, flexible dies) are changed automatically. Waste stripping is also fully automated. Eliminating traditional analogue bottlenecks, the Master DM5 is the very first digitized “non-stop” label press.’

The Master DM5 is claimed to have the widest digital color gamut in digital printing, alongside an exclusive screening and digital front end (DFE).

Ink-on-Demand (IoD) is an optional extra for DigiFlexo print units, a system that replaces conventional inking reservoirs with a single rubber pipe that dispenses 30 grams of ink to the print unit. The system eliminates ink trays and chambered doctor blades and performs fully automated washing of the print unit in less than one minute.

It also has a full range of added value capabilities, including coatings, varnishes, tactile effects, 3D effects, hot stamping, cold foil, embossing, die-cutting, punching, silkscreen, flexo and digital Variable Data Printing (VDP).

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.