Flexo Wash to launch cleaning equipment for printed films

New technology will help converters to clean and reuse printed films and further minimize their environmental impact.

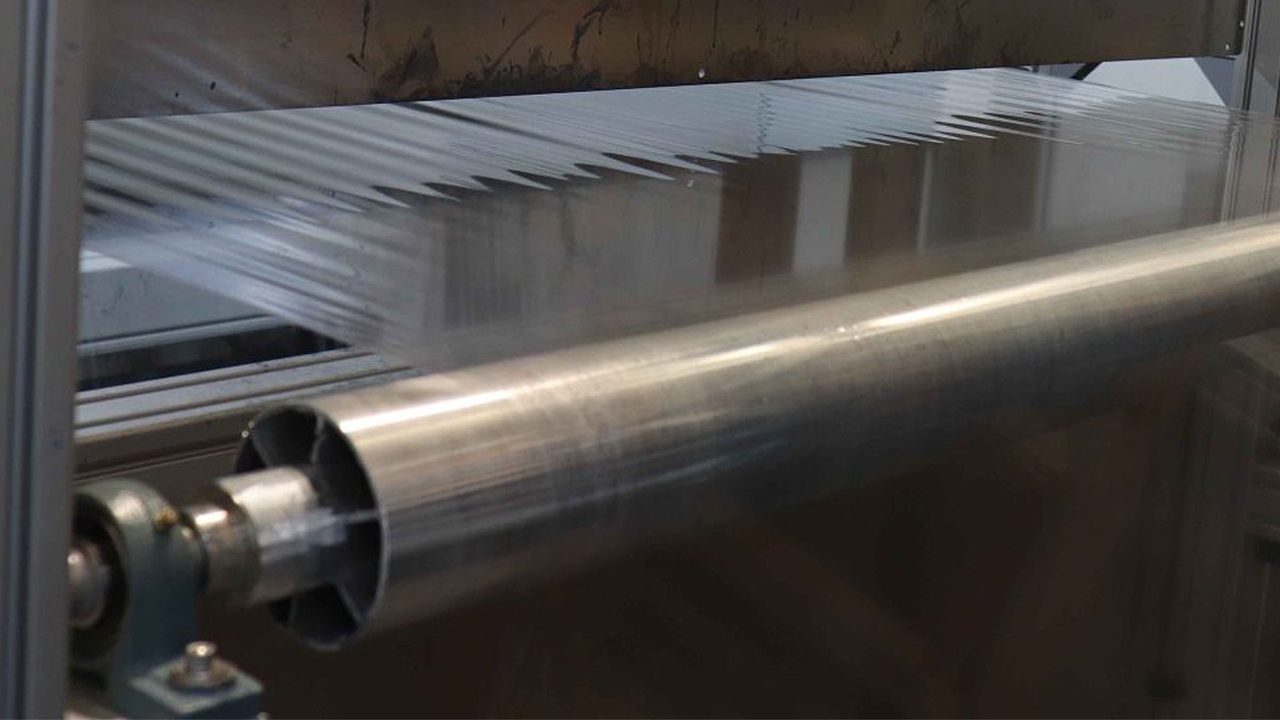

Flexo Wash, a specialist flexo part cleaning equipment manufacturer, has confirmed it will be launching its latest development enabling converters to clean and reuse printed films at the end of this month.

According to Flexo Wash, plastic film is widely used in various industrial applications and has become a significant environmental concern due to its contribution to plastic pollution.

‘At Flexo Wash, we understand the printing industry's struggle to have dirty printed film and having to dispose of it. Several customers have raised this issue, and where there is an issue, Flexo Wash is driven to find the solution. So now, Flexo Wash has developed this solution allowing converters to clean and reuse printed films,’ said the company in a statement.

During the last year, Flexo Wash has built and run extensive testing of the new equipment to help printers reuse their printed film.

Flexo Wash will run live product launch and talk further about this crucial step in reducing costs and promoting sustainability in the printing industry on April 30, at 9:30 am EDT.

The latest development is in line with the company’s strategy to extend the lifespan of printing film, reduce waste, offer cost savings and minimize environmental impact.

‘This new project is the result of our commitment to deliver innovative solutions that benefit both our customers and the environment,’ added managing director of Flexo Wash, Anders Kongstad.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.