Flint launches automated plate processing line

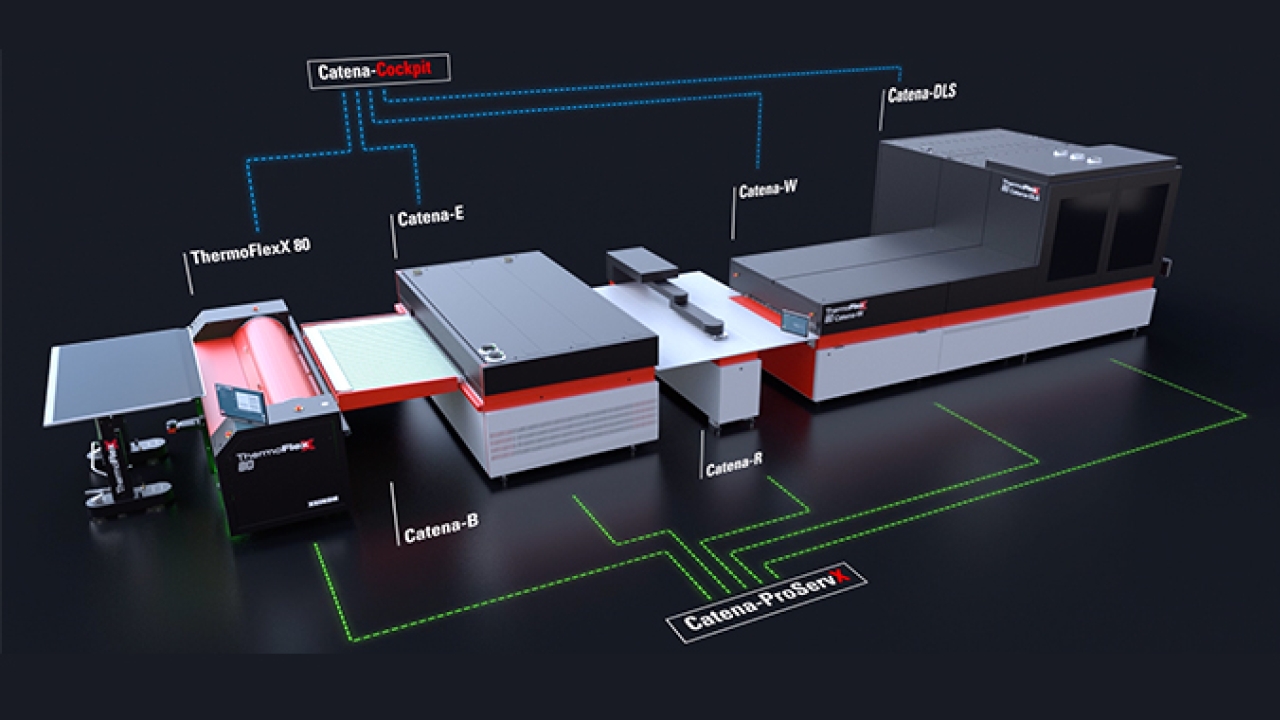

Flint Group has launched a fully automated plate processing line, the ThermoFlexX Catena+, which integrates a series of existing ThermoFlexX modules. These include Catena - E, for UV LED exposure; Catena - W, a solvent plate processor; and Catena - DLS, a dryer, light finisher and plate stacker combination with robotized plate transport.

The Catena+ system allows these modules to be configured in a variety of ways to deliver different levels of automation. A Catena-DLS module can be connected to a Catena-W for automatic plate processing. The Catena-DLS has ten drying units, seven stacking positions and a light finisher. Robotic movement ensures that plates are fully finished with no operator intervention after loading into the washer.

‘The Catena-DLS is the missing piece on our way to fully automated flexo plate processing. In combination with our ThermoFlexX imager, the recently released Catena-W and the Catena-E UV LED exposure, we provide a state-of-the-art, fully automated and integrated flexo plate processing system,' stated Uwe Stebani, general manager Xeikon Prepress.

The system is optimized for use with Flint Group’s ThermoFlexX Woodpecker surface screening software and flexo plates, but is also designed as an open system. This means Catena+ allows easy loading of plates from other imagers into the Catena-E LED exposure unit. Plates from other exposure frames can also be loaded to take advantage of the WDLS.

The full line Catena+ includes Catena Cockpit, which provides a continuous status report on plate processing,progress and expected time of completion, while Catena ProServX software allows constant machine monitoring of all modules.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.