Labelmen to launch intermittent offset press at Labelexpo

Labelmen will launch its RS-350PS full rotary/intermittent offset press at Labelexpo Europe on stand 6H130.

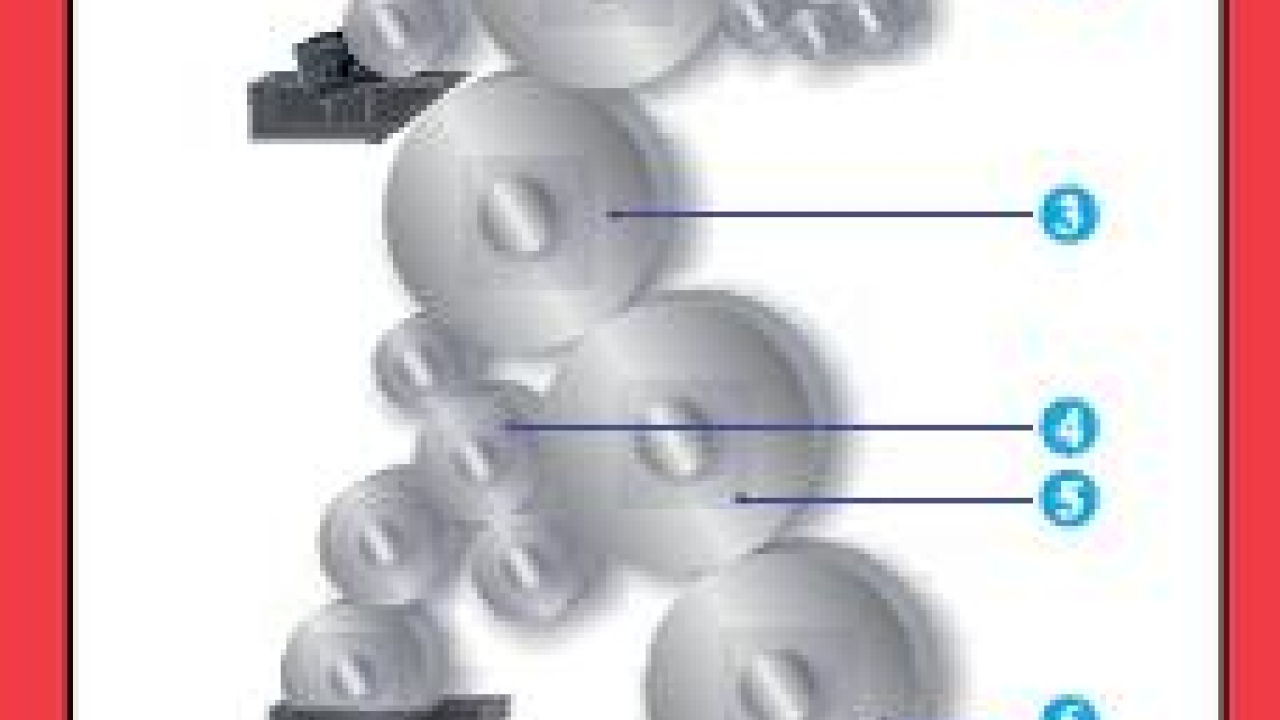

The servo-driven machine addresses the market trend towards shorter runs, says the company, thanks to the press’s Ani-Print inking system, which provides consistent ink application and shorter make-ready times – according to Labelmen, waste can be reduced by up to 90 percent compared to traditional offset presses. Together with special design of inking form rollers, printing quality can be fulfilled without ghosting.

The intermittent nature of the machine allows jobs to be printed in different sizes via simple computerized operation without changing cylinders. However, says the company, the biggest defect of normal intermittent printing systems is the drawing back of material by a drive roller which, with different length settings, can cause the material to be scratched; and furthermore, they cannot equip corona treatment, web guiding and cold stamping. In order to address these concerns, Labelmen’s R&D department has developed a special tension control system, which is placed after the unwind and allows the RS-350 PS to be fitted with corona treatment, web guiding and cold stamping units. The material can be fed smoothly with in an intermittent action, and then rewound in full rotary after printing. Additionally, a Martin Automatic non-stop butt splicer, turret rewinder and accumulator can be installed to enhance efficiency and reduce waste.

Additional features of the new press include CNC one-touch make-ready design, a dampening solution circulation system from Technotrans, multi-functional flexo printing stations, and remote monitoring and diagnostics.

Pictured: The Ani-Print inking system can help to reduce waste by up to 90 percent, says the company

Click here for more stories about Labelmen on L&L.com.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.