Schober unveils rotary embossing and hologram system

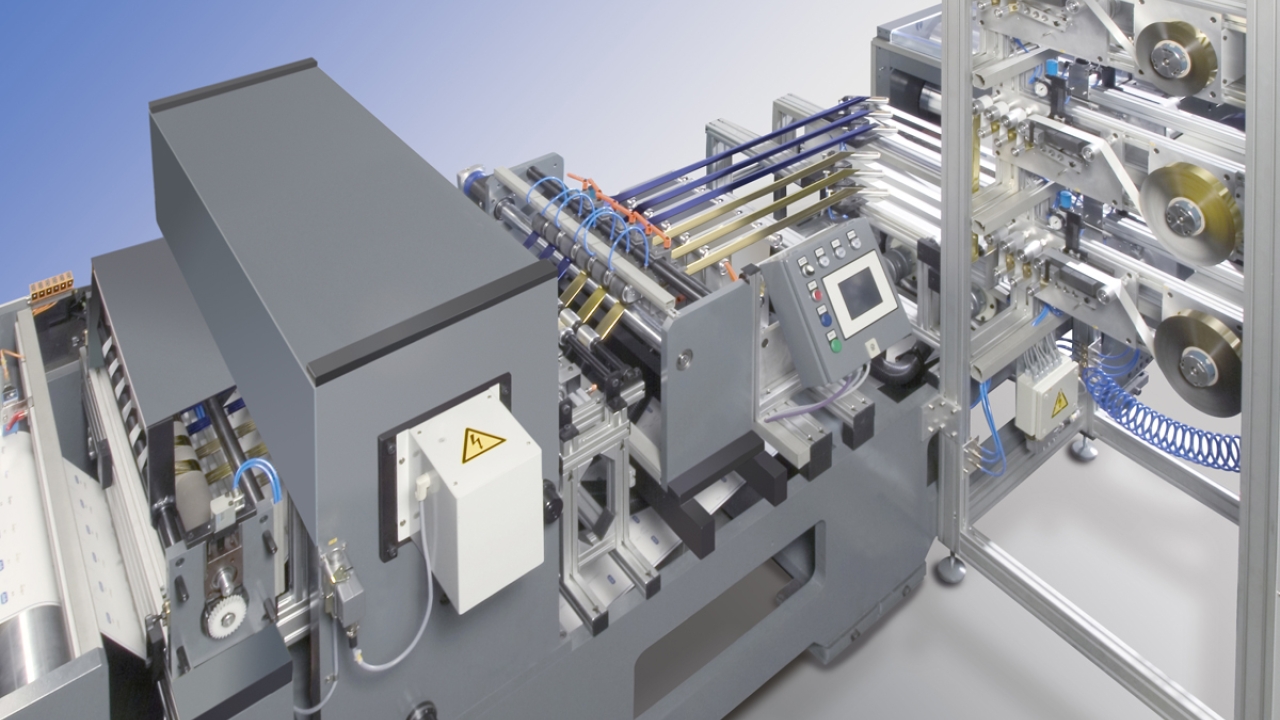

Schober has introduced its VHFA 2650 rotary heat embossing and hologram system, aimed at eliminating product counterfeiting and piracy while enhancing the aesthetics of product packaging.

Available for in-line or off-line applications, the system is offered in working widths to 850 mm (33.46 in) with speeds to 150 m/min (492 ft/min). Digital drive technology is said to ensure flexibility, smooth start-up and operation, as well as high register precision with minimal waste.

Operating parameters such as temperature, foil registration and speeds can be easily stored, thereby reducing set-up time for future projects. These features make the VHFA 2650 suited to packaging and converting applications within the pharmaceutical, textile, automotive, consumer goods, and food and beverage packaging industries, and others where brand image and reputation are vital.

Sealing segments are individually adjustable in radial and axial directions. The foil unwind system allows reel sizes of a maximum diameter of 400 mm (15.75 in). Every reel has individual tension control through dancer/unwind brake system. A foil saver feeding system with servo-driven feed rollers is provided, as is a foil guiding system. A servomotor-driven heat transfer cylinder is synchronized with the register control system of the printing press.

Click here for more stories about Schober on L&L.com.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.