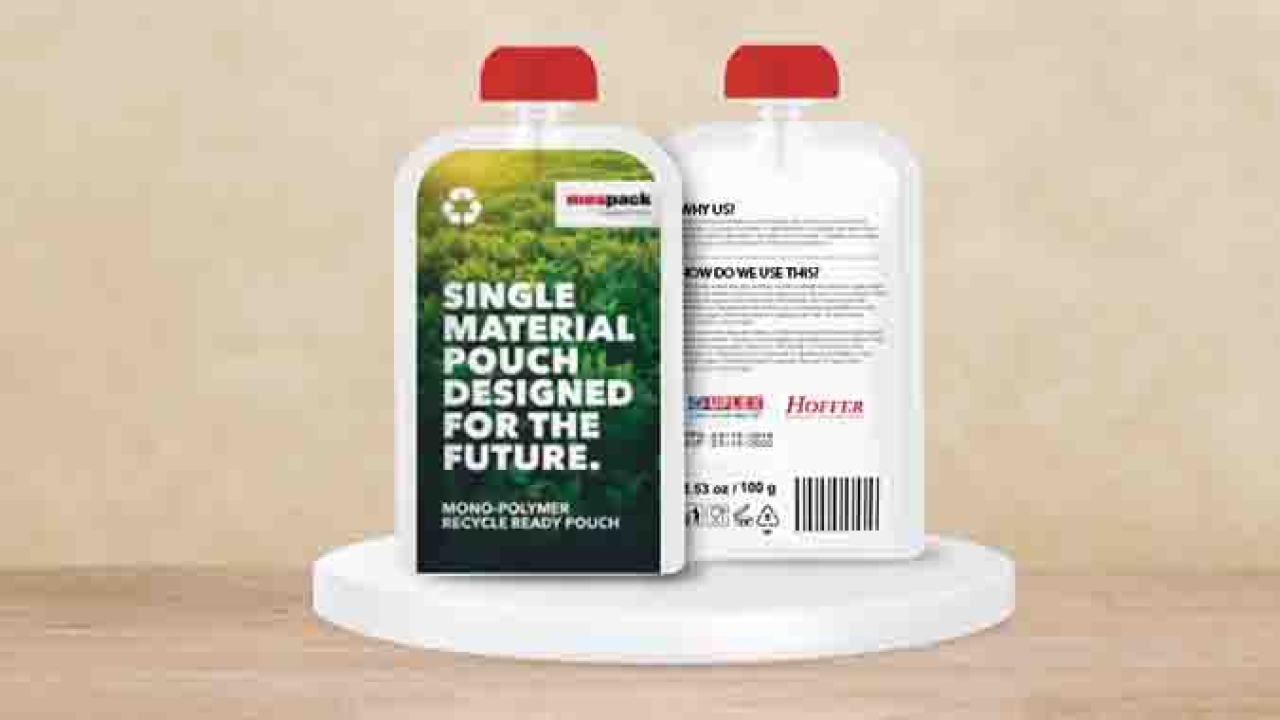

Uflex, Hoffer Plastics and Mespack launch recyclable mono-polymer hot-fill pouches

Uflex has partnered with Mespack, manufacturer of flexible packaging, end-of-line, and soluble pods equipment and Hoffer Plastics, manufacturer of custom injection molded parts, to develop 100 percent recyclable mono-polymer hot-fill pouches. The pouch is 100 percent recyclable with its new mono-polymer structure and spout caps.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.