Rapid growth in Guatemala

Guatemala-based Flexsa has grown rapidly since its foundation in 1997, due to an expanding local market and regular investment. James Quirk reports

When label converter Flexografica S.A., or Flexsa, was founded in 1997, many of Guatemala’s leading brands were importing 100 percent of their labels from outside the country. But over the last 13 years, rapid expansion of the local market, coupled with regular investment in new technology, have seen the company twice move to larger facilities to accommodate annual growth of up to 25 percent.

Flexsa began by printing clothes labels with a Mark Andy 830 press. ‘Once we were present in the market, we quickly saw the need for quality products,’ says managing director Carmina Pinto. ‘There were competitors, but generally there was a limited offering to the market.’

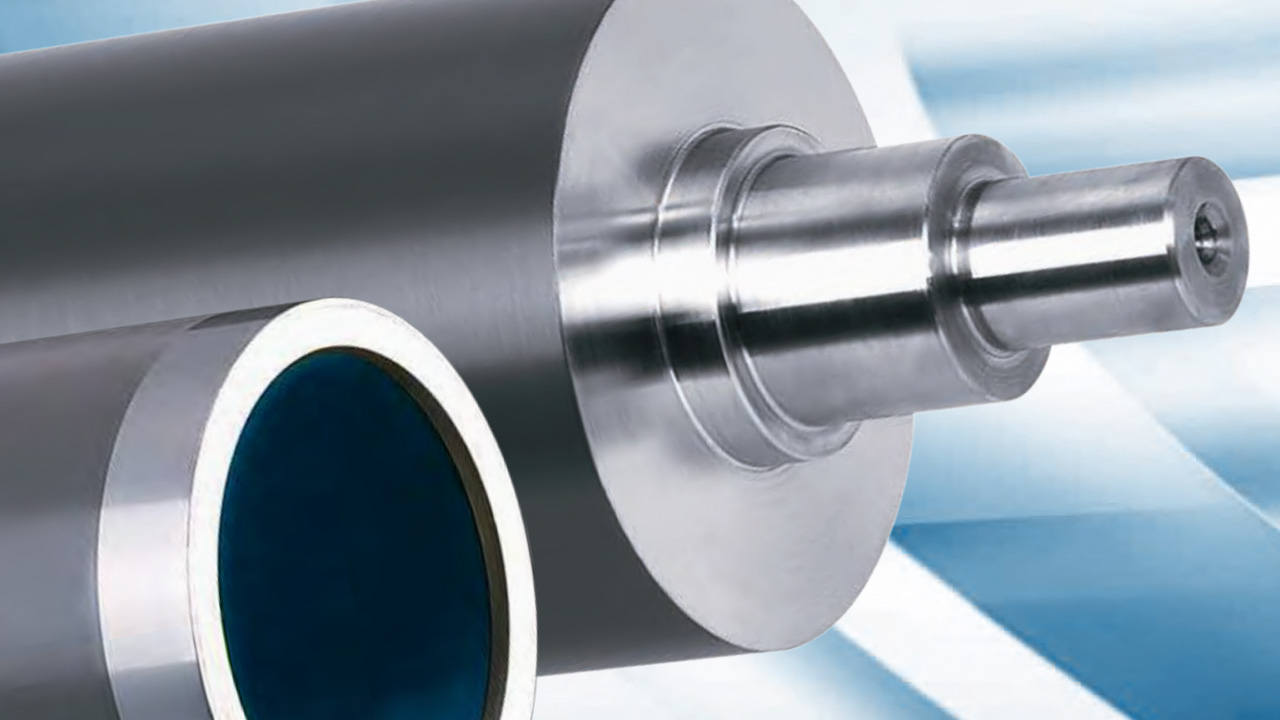

Over the next seven years, the company invested in various Mark Andy presses plus additional finishing equipment. A mixture of 6- and 8-color machines, they also brought the company UV varnish, inline lamination, hot stamping and cold foiling capabilities. Rotoflex machines handle finishing.

In 2007, Flexsa installed shrink sleeve equipment from Karville and an HP Indigo digital press. A year later came a full UV Mark Andy machine with die-cutting and inline lamination, which produces wraparound labels and shrink sleeves. Presses are operated in two 8-hour shifts, but will often run for 24 hours during busy periods.

The Mark Andy presses boast impressive records of reliability. ‘In 13 years, we’ve never had one of the presses completely stop because of a technical problem,’ says Pinto. ‘It’s a remarkable record. The first Mark Andy press that we installed continues to produce the same quality of products today.’

‘There is always growth in this market,’ says Pinto in explanation of the company’s regular investment in new technology. ‘If you don’t invest in new machinery and continuously improve the quality of your production, someone else will. The demand for quality in the local market is increasing. Ten years ago, we were already producing good quality, but even since then it has improved a great deal.’

The company’s rapid growth, which has mirrored that of its local market, has necessitated a number of factory moves. In its original facility for four years, Flexsa then moved to a 2,000 square meter site. But continued expansion – often at 25 percent a year, says Pinto – forced a further relocation to its current factory, of 3,000 square meters, three years ago. Anticipating continued growth, this facility, which houses 65 staff, has plenty of room for further expansion in both production and office space.

Indeed, Pinto says that growth was still at 10 percent a year when the recession hit. No business was lost during the downturn and growth returned in September 2009. Since the beginning of this year, Pinto reports that normal service has been resumed.

Technology diversification

Flexsa’s investment in new technology has also been motivated by the desire to expand its product offering in what remains a comparatively small local market, despite its rapid growth since the company’s foundation. Guatemala has a population of 13 million people. The ability to offer a wide range of products and technologies has been an important part of the company becoming one of the country’s leading label converters.

Investment in shrink sleeve equipment, for example, was driven by market trends and has seen its production quickly rise to 25 percent of the company’s total output. Digital technology, meanwhile, has allowed Flexsa ‘to cater more effectively to short run work’, says Pinto. ‘We had felt a limitation in our offering in terms of short runs, which the local market increasingly needed. The cosmetics sector in Guatemala, for example, is mostly made up of short runs with a great deal of product variation. Digital technology has therefore opened many doors to us that we could not enter with flexo.’

The HP Indigo ws4050 is largely dedicated to cosmetics and pharmaceutical label production. Pinto reports that clients like the speed of turnaround from design to delivery, but warns that the technology has its limitations in other areas. ‘In Guatemala and in Latin America in general, volume is found in consumer products such as household goods, personal care and beverages. These are often very cheap, so cannot be handled cost-effectively by digital.’ Of the company’s 700 jobs each month, 150 are short runs printed digitally.

In a further effort to diversify its offering, Flexsa distributes applicators and adhesive tapes, and also manufacturers its own material for use in guarantee stamps for sleeve necks.

Despite shrink sleeves’ increasing share, self-adhesive labels remain Flexsa’s core business with 75 percent of production. The remaining 5 percent is dedicated to paper products with no adhesive. The local market for textile labeling, the company’s original production, has decreased, but remains a part of Flexsa’s business.

Ninety percent of the company’s labels serve the Guatemalan market, with El Salvador, Honduras and Nicaragua importing the remainder. Pinto says that the company hopes to increase its exports to its neighboring Central American countries. Export to South America is hindered by large distances and poor infrastructure. And what about North America? ‘It would be possible logistically,’ says Pinto, ‘but the market is very competitive and there isn’t the need. The biggest financial outlay is on materials. We import them from the US, so we wouldn’t bring much of a price advantage.’

Aside from Fasson and UPM Raflatac materials imported from North America, Flexsa buys a small amount from Colombia and Argentina. But Pinto reports that not all the materials that the company uses are available from its fellow Latin American nations.

Regular investment also takes place in Flexsa’s pre-press department, where a Degraf Concept platemaking machine was installed last year. It joins further pre-press equipment from Agfa, EskoArtwork and Dupont. Inks come from leading US-based suppliers. ‘We believe in the importance of standardization and stability, so we don’t change suppliers often,’ says Pinto.

Flexsa also pays close attention to the training and development of its employees. With little local technical support, the company brings in experts from various areas to give seminars to its pre-press and press operators. The company has benefited from stability within its workforce: managers in the production and sales departments have been there since the company’s foundation 13 years ago, while the accounting department, too, still counts on employees from this time.

Pinto is aware of the growing importance of environmental sustainability, but is frustrated at the lack of local infrastructure in Guatemala catering to recycling of waste. ‘Waste recycling needs to be facilitated by local support,’ she says, ‘but it doesn’t exist here.’ Instead, Flexsa sells its waste to another company which uses it as fuel. To avoid the threat of counterfeiting, no whole label leaves the factory as waste; it is compacted in the plant first.

‘We need to focus more on recycling as an industry,’ says Pinto. ‘The process must be facilitated. It is the responsibility of everyone involved: the converter, the end user and the material manufacturer.’

Pinto has extensive experience in wide web technology and the packaging sector, and cites flexible packaging as a possible avenue for expansion in the future. ‘But there has been so much growth in the label market that we have not needed to expand into packaging yet,’ she says.

2010 has been a rare year for Flexsa with no investment in new technology. Pinto emphasizes the need to ride out the effects of the economic downturn, but says that further installations are being planned for 2011.

This article was published in L&L issue 6, 2010

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.