Masterpress joins BeFORE project

The EU-funded initiative tests a single-layer pouch for high-barrier recyclability compliance.

Masterpress has joined BeFORE – Barrier for Recycling, an EU-funded research initiative under the 37th Cornet program that seeks to provide practical insights into the industry shift from traditional multi-material structures toward mono-material packaging designs, delivering product protection and compliance with the EU's Packaging and Packaging Waste Regulation.

The BeFORE consortium brings together partners from Belgium, Germany and Poland, including industrial manufacturers, research institutions and packaging value-chain organizations. Masterpress participates in the project through Natureef, a Polish association bringing together companies from the packaging, food production and recycling sectors under joint research projects.

'BeFORE is a natural extension of our company's long-term commitment to helping brands transition toward truly circular packaging solutions,' said Gabriel Magdaleno, strategic product development and marketing director at Masterpress. 'In the context of the EU PPWR, BeFORE positions us to help brands navigate the regulation's implementation phase by ensuring that flexible high-barrier packaging can be recyclable and, at the same time, deliver reliable product protection.'

High-barrier plastic and paper packaging play a critical role in protecting sensitive products, such as food, cosmetics and personal-care items, by safeguarding against oxygen, moisture, fats, oils and other environmental factors. Traditionally, many of these structures rely on complex multi-material combinations that cannot be recycled in today's widely used mechanical recycling systems.

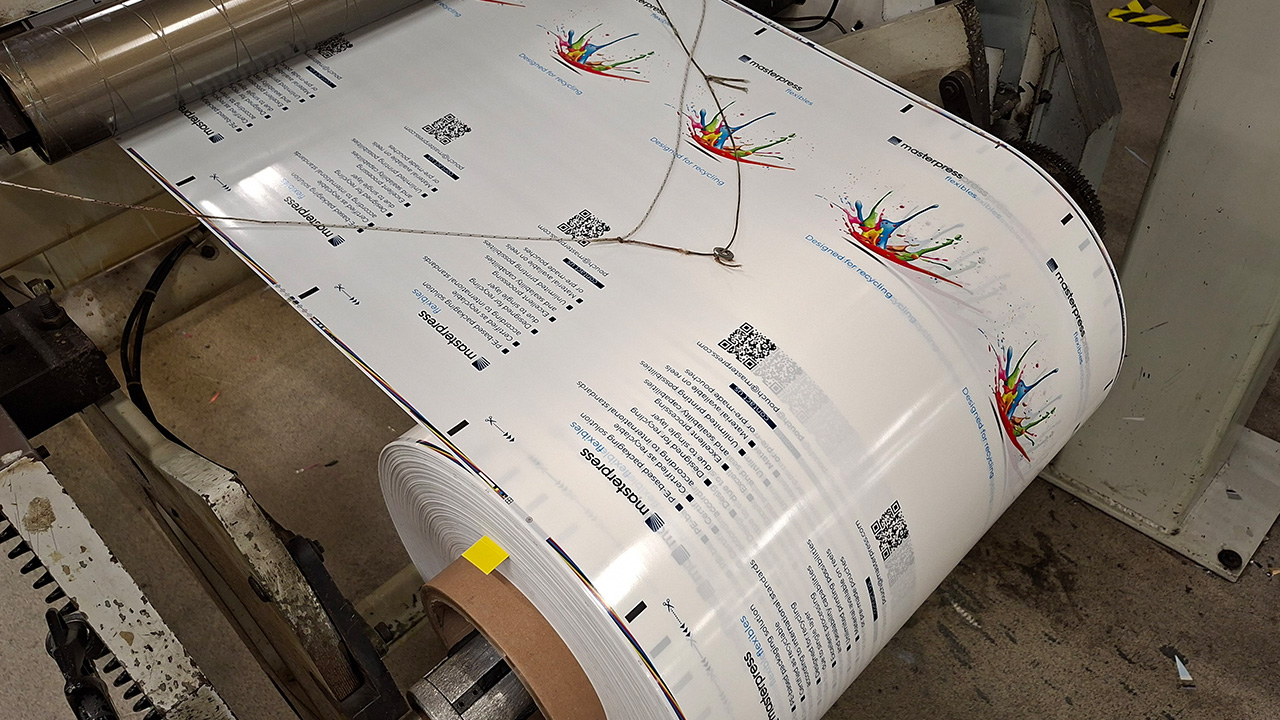

As part of BeFORE's work on high-barrier, co-extruded polyethylene stand-up pouches, Masterpress contributes one of the project's key plastic case studies: the company's single-layer, non-laminated stand-up pouch for liquid soap. Unlike traditional laminated pouches, which use several different materials and cannot be recycled in standard PE recycling streams, Masterpress's pouch is made from a single mono-material PE/EVOH structure engineered to sort correctly in recycling facilities and work within existing PE recycling systems.

'High-barrier flexible packaging has historically been difficult to recycle, but this project demonstrates how collaborative R&D, connecting science, industry and legislation, can accelerate real change,' added Jakub Pędziński, pouches business development leader at Masterpress. 'By testing our single-layer pouch within this international consortium, we are contributing to innovations that keep materials in the loop and support Europe's transition toward sustainable packaging.'

As part of the BeFORE project, the pouch is being tested in several key areas, including barrier performance, strength and shelf-life behavior, safety and migration assessments, performance on automated filling and packaging lines, and recyclability evaluated according to international recyclability guidelines.

The project runs from March 1, 2025, to February 28, 2027, and is co-financed by Poland's National Centre for Research and Development, with a total budget of 1,560,693 PLN (431,026 USD), including 1,469,385 PLN (405,809 USD) in co-funding.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.