Universal Converting Equipment reduces energy usage

Universal Converting Equipment has introduced a package of energy consumption reducing features into its range of slitting and winding machinery.

Technical director Dave Ward explained, ‘We design our machinery to be as frugal as possible with energy and have identified significant areas where energy savings can be made; in some cases functionality and performance has been increased as a positive side effect. One of the ways we achieve this saving is by using the latest high efficiency (Efficiency 1) AC motors, with the most up to date AC Vector Drives. Commonly we design in regenerative motors rather than more traditional pneumatic brakes so rather than braking energy being lost (as heat) it is turned into electricity and used by other systems within the machine.

‘In some applications the brake energy is enough to reduce power consumption of the machine by 40 percent or more. Our machines intelligently turn off unused systems (how often do you walk past machines with hydraulic packs (sometimes on guiders) that are running whether the machine is in use or not) and avoids fan systems that run even when not required. Wherever possible we have engineered hydraulic systems out of our equipment. Even our touch screens are set to go into power save mode when not used for a period.’

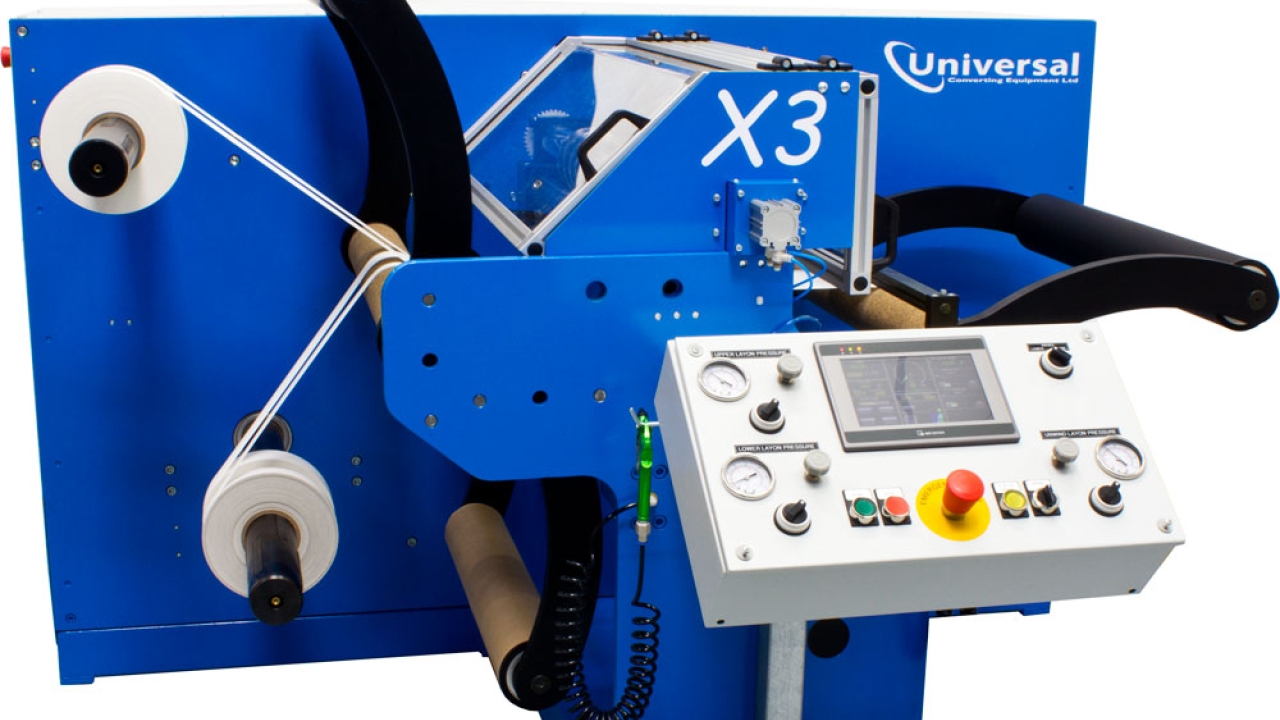

Pictured: Universal X3 slitter rewinder

Click here for more stories about Universal Converting Equipment on L&L.com.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.