Blair Labeling installs Esko Automation Engine QuickStart

Denver-based Blair Labeling has installed Esko Automation Engine QuickStart for Labels, and was able to reduce its manual prepress workload by more than 30 percent, feeding its five flexo presses and new digital press.

Blair Labeling, a woman-owned and minority-owned business, has been providing multicolored, prime, promotional and industrial pressure sensitive labels—as well as decals, tamper evident constructions, thermals, patterns, tags, hangers and card products—since 1986. In addition to working on the presses, their staff of 20 performs die cutting, perforating, punching, lamination/UV coating and graduated screens—all in-line. Blair also has a full-service art department capable of providing graphic design and prepress services.

QuickStart is a pre-configured workflow software that addresses the key challenges that constrict throughput and cause inefficiencies in label manufacturing. It includes tasks such as packaging preflighting, checking barcodes including full quality report on the barcodes, trapping, step-and-repeat, Smartmarks and control strips as well as automated job reports.

Blair has been working with Automation Engine QuickStart for about three months.

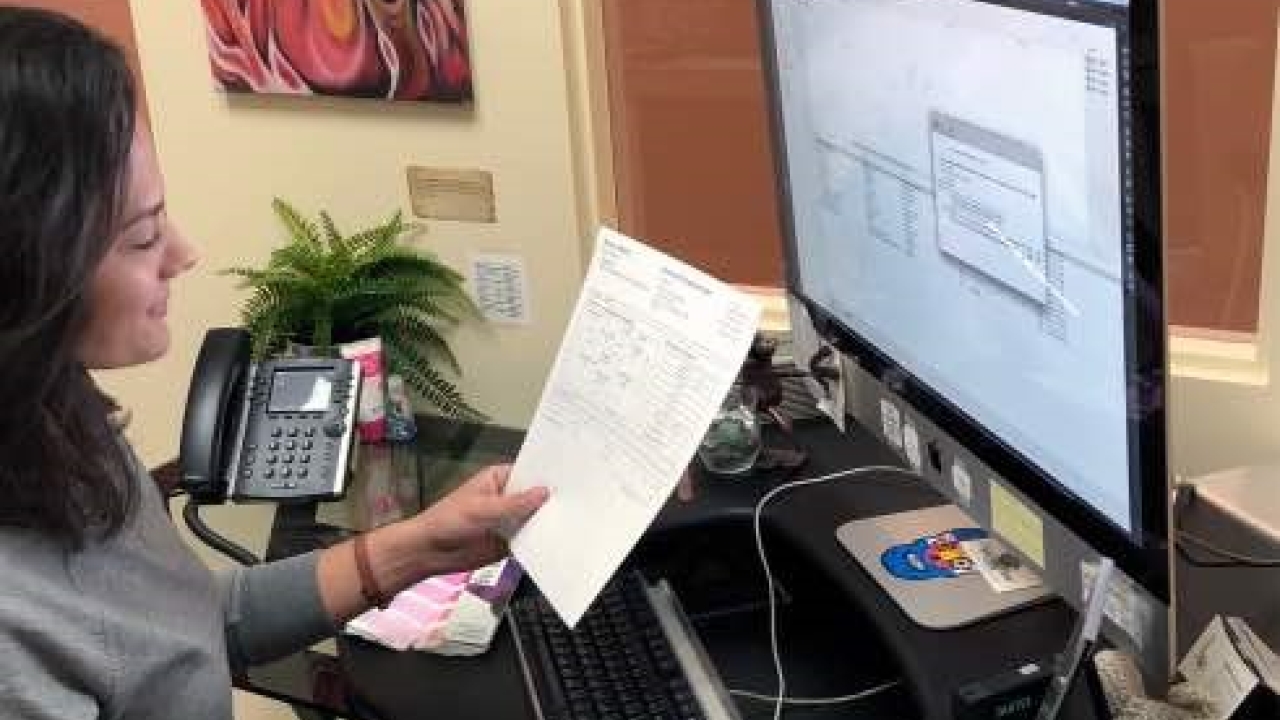

Marco De La Vega, CFO, Blair said: ‘One of the primary problems we had was managing products. I particularly love that now I can search our product database and use it as reference—not necessarily just for art. I can easily search for a product, based on a key word on the label. It’s incredible. The system pulls up everything. We can find the job ticket of the last time we ran a job, which shows us if there were any changes—the most up-to-date version of the product. For example, we have a customer that has the same flavored product, but different nutritional copy. It was previously error prone because it was tough to know what copy to use. This system now shows me the correct proof and approved changes made to the copy across the entire board.’

De La Vega was also looking for a system that was foolproof. ‘It’s nice that 98 percent of all our jobs can be done automatically. We manually work on 2 percent of our jobs that involve difficult tasks, but this is the work we would want to do, anyway. Our prepress artist is very capable and can figure out most issues without help. It’s nice that we do not require a workflow expert.’

On average, Blair processes about 20-25 individual jobs per day—and each job has three to four pieces of artwork on it. Since they added their digital press—around the same time they installed their Esko workflow—the number of jobs has not increased: they have just moved more accounts over to digital to help accommodate the demand on the flexo presses.

‘The number of copies has increased per job. Per die size, we run anywhere between 20-35 pieces of artwork on digital,’ said De La Vega. ‘However, overall we anticipate 6 percent growth over last year, while platemaking has decreased 10 percent because of our digital press. As a result, we expect to grow while also realizing cost savings. We select multiple pieces of artwork and the system steps them out. It used to take a long time in prepress. I would absolutely attribute this to the efficiency measures taken in prepress as well as moving a lot of work over to the digital press.’

Blair prints private label water bottle labels on their digital press for a company that, in two months, has required 86 different products. Blair likes to gang the products and run different labels concurrently.

‘It has saved us so much time. We print five different labels across—whatever five products require the same quantities—and two around,’ he said. ‘Before, we could only print labels of the same product. Even with only fifteen minutes development work per file, the time adds up. It has allowed us to remain competitive, assuring us that art time is covered in the cost.

Blair has eliminated many operator errors. ‘The system does exactly what you tell it to do. It will knock out work and show it to you. Before, working on step and repeat, I would sometimes pull the wrong copy. Now the system shows us the correct artwork—and, of course, with the correct parameters, it will print correctly,’ De La Vega said.

‘Automation has helped us become very productive—and it has been easy to do. And, as we grow familiar with Automation Engine QuickStart, we continue to grow and implement new capabilities,’ he said. ‘Without a doubt, if I were doing this again, I would install Automation Engine QuickStart, and would be willing to risk my job on its reliability. I am confident that there is nothing the system can’t do.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.