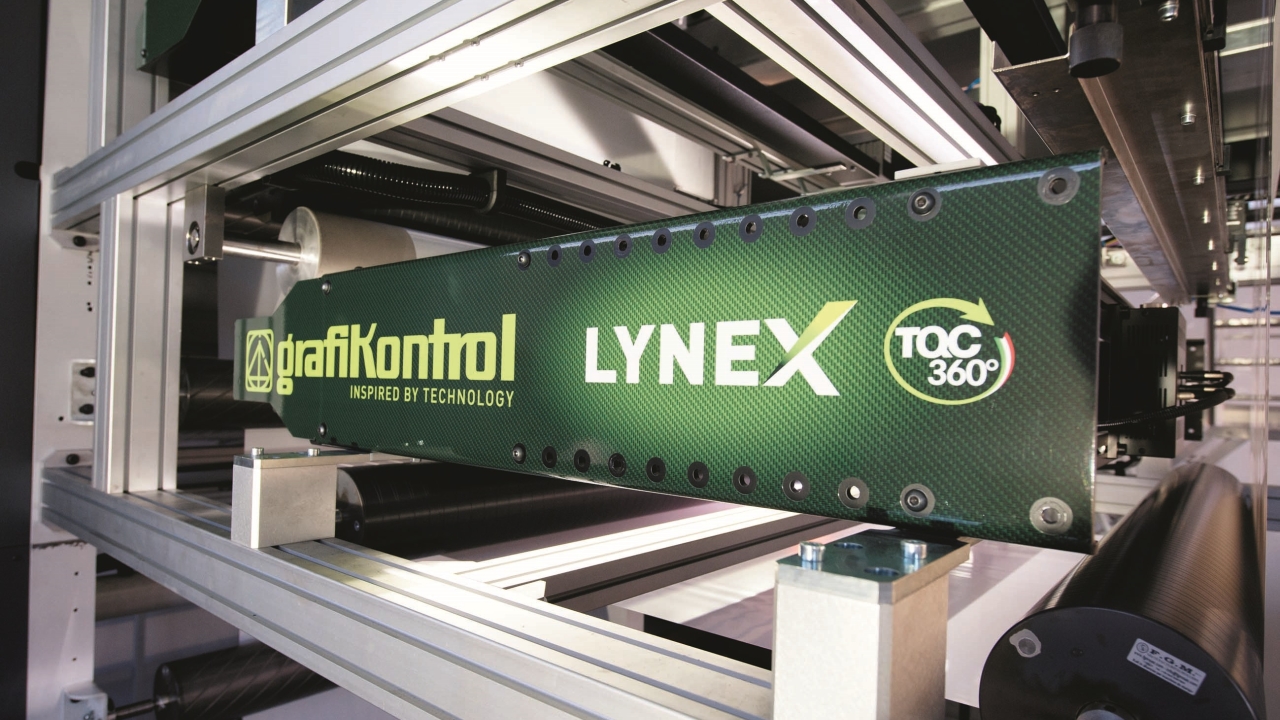

Grafikontrol brings Lynex to the label market

Grafikontrol, a manufacturer of control systems for the printing industry, will present its Lynex 100 percent inspection system for printed webs to the label market for the first time at Labelexpo Europe 2017.

Lynex enables automatic detection and classification of every defect, according to Grafikontrol. The system combines one or more linear color cameras, configurable as needed, that can work at production speeds up to 900m/min without changing the image resolution, it is claimed. Lynex can be used for defect checking with any type of printing and on any substrate. White LED lighting ensures quality and light distribution without any degradation of the image, even on reflective materials and inks. A multitasking interface implemented on a 23in high-resolution multitouch monitor means the operator can analyze the entire format in real time and benefit from automatic detection of both print and media defects. Immediate alarm, when imperfection is detected, eliminates defective material. Lynex also provides production analysis and data collection.

Lynex is part of the Grafikontrol TQC-360° modular platform, developed to provide printers with an overarching system to ensure quality.

‘We are proud we have become one of the protagonists in the label industry in just two years, and our control systems are present at various European and American label printers,’ said Paolo De Grandis, Grafikontrol sales director and partner. ‘Attention to customer needs has led us to create more and more powerful systems, which guarantees the detection of defects of dimension up to 0.1mm across the printed area.’

Grafikontrol will show live demonstrations of Lynex, which is also to be shown by Lombardi Converting Equipment installed on a web press.

Labelexpo Europe 2017 takes place September 25-28 in Brussels, Belgium

Read L&L’s Labelexpo Europe 2017 new product showcase in issue 4

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.