Indonesian converter’s bold flexo investment pays off

Five Omet iFlex presses position Indolabel as one of the leading manufacturers in Southeast Asia.

PT Indolabel Surya Pratama has completed a remarkable transformation from traditional letterpress to advanced flexographic printing with the acquisition of five Omet iFlex presses, positioning itself as one of Indonesia’s leading label converters and a driving force in the Southeast Asian label market.

The Jakarta-based company’s journey began with a strategic decision to modernize its production capabilities to meet growing demand for high-quality, short-run and sustainable label production across diverse industries, including pharmaceuticals, food and beverage, cosmetics, electronics and logistics.

“What Indolabel has built here is nothing short of outstanding. The facility is one of the most impressive in Southeast Asia”

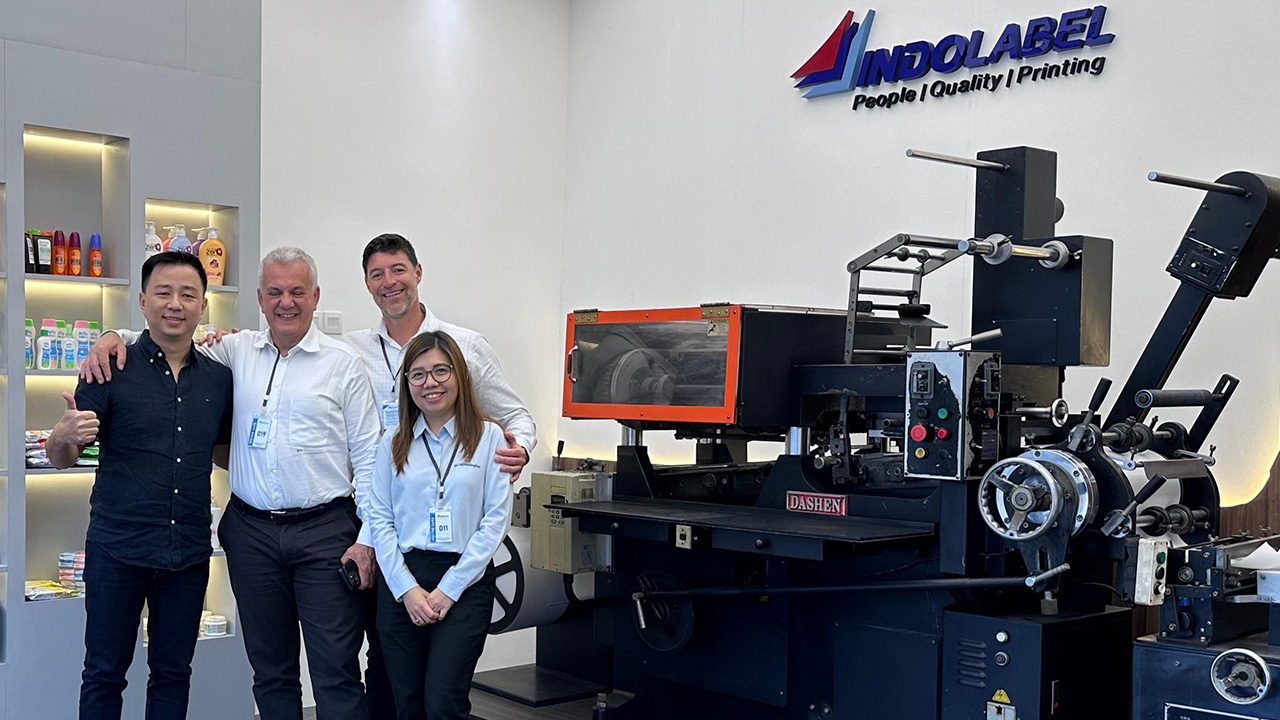

Over the past several years, Indolabel has systematically invested in flexographic technology, with each press installation building upon the successes of its predecessors. The latest acquisition, a fifth Omet iFlex press that was recently showcased at Labelexpo Southeast Asia, demonstrates the company’s unwavering confidence in both the technology platform and its strategic partnership approach.

This progressive investment strategy reflects broader market dynamics across Southeast Asia, where converters are responding to evolving customer demands for more sophisticated label applications, shorter run lengths and faster turnaround times. Indolabel’s approach has positioned it at the forefront of this transformation, creating a competitive advantage that extends well beyond its domestic market.

Partnership drives technology adoption

The transformation has been supported by a strong partnership with Jet Technologies Indonesia, the exclusive dealer and service partner for Omet across Indonesia, Vietnam, Singapore and Malaysia. This relationship has extended beyond equipment supply to encompass comprehensive training, optimization and production planning support that has been crucial to Indolabel’s success.

‘The simplicity and efficiency of the Omet iFlex made it the right machine for our team and our production needs,’ says Benny Kartaraharja, managing director at Indolabel. ‘But just as important has been the strong, ongoing support from Jet Technologies. The service didn’t stop at installation. They’ve been a true partner throughout our transition from letterpress to flexo.’

The partnership model exemplifies how successful technology adoption requires more than equipment procurement. Jet Technologies has worked closely with Indolabel throughout every stage of its transformation, providing expertise that has enabled the company to maximize the potential of each press installation.

Jack Malki, director at Jet Technologies, emphasizes the consultative approach that has characterized the partnership. ‘We take a consultative approach with all our clients, and in the case of Indolabel, we’ve partnered with the company every step of the way, from planning and investment to training and optimization,’ he explains. ‘The result is a production setup that’s both scalable, efficient and well positioned to support Indolabel’s continued growth.’

This comprehensive support model has enabled the Indonesian converter to avoid many of the common pitfalls associated with major technology transitions. Rather than simply installing equipment and hoping for the best, the partnership has ensured that each press installation has delivered immediate productivity gains while building capabilities for future growth.

The relationship has also facilitated knowledge transfer that has elevated Indolabel’s internal capabilities. Through structured training programs and ongoing consultation, Jet Technologies has helped develop Indolabel’s technical expertise, creating a more self-sufficient operation that can adapt quickly to changing market requirements.

Indolabel’s investment extends beyond equipment to encompass a state-of-the-art facility located near Jakarta, which has impressed industry leaders and set new standards for label production in the region. The facility represents a comprehensive approach to modernization that addresses every aspect of the production process.

Marco Calcagni, sales and marketing director at Omet, recently visited the site and praised its scale and sophistication. ‘What Indolabel has built here is nothing short of outstanding,’ says Calcagni. ‘The facility is one of the most impressive in Southeast Asia. It’s a world-class production hub, and we are incredibly proud that Omet plays a central role in Indolabel’s journey.’

The facility design reflects Indolabel’s understanding that successful flexographic printing requires more than advanced equipment. Environmental controls, workflow optimization, quality control systems and material handling capabilities have all been carefully planned to support high‑performance production across multiple product categories.

The investment in infrastructure demonstrates the company’s long-term commitment to the Indonesian market and its confidence in continued growth. By creating a facility that can accommodate future expansion and technology upgrades, the company has positioned itself to respond quickly to evolving market opportunities.

The facility also serves as a showcase for Indonesian manufacturing capabilities, demonstrating that domestic converters can compete effectively with international competitors through strategic investment and operational excellence. This has important implications for the broader development of Indonesia’s packaging industry.

Strategic growth

The successive investments in Omet iFlex technology reflect Indolabel’s confidence in flexographic printing as the optimal approach for meeting evolving market demands. Each press acquisition has added capacity and flexibility to handle the growing requirements for short-run, high-quality production while maintaining efficiency and quality standards.

‘The iFlex has consistently delivered on performance, ease of use and quality,’ notes Malki. ‘We’re thrilled to see Indolabel’s trust in the technology reaffirmed with each investment.’

The company’s evolution from traditional letterpress to advanced flexographic printing mirrors broader industry trends toward more flexible, efficient and sustainable production methods. As demand continues to rise across Southeast Asia for sophisticated label applications, Indolabel’s investment strategy positions it to capitalize on market growth while maintaining operational excellence.

The Omet iFlex platform offers several advantages that align with market trends in the label industry. The servo-driven technology provides precise registration and consistent quality, while the modular design allows for configuration flexibility that can accommodate diverse application requirements. These capabilities are particularly valuable in markets where customers demand both quality and responsiveness.

The investment in multiple iFlex presses also provides operational advantages through standardization. By building expertise on a single platform, Indolabel has created efficiencies in training, maintenance and production planning that would be difficult to achieve with a mixed equipment base.

Technology enables ambitious goals

Indolabel’s approach to technology adoption demonstrates how strategic partnerships can accelerate transformation in the label printing industry. The company’s experience highlights the importance of comprehensive support throughout the transition process, from initial planning through ongoing optimization.

‘This partnership has empowered us to chase our ambition of becoming one of the top label printers in Indonesia,’ states Kartaraharja, reflecting on the journey that has seen the company install five Omet iFlex presses over recent years.

The investment trajectory showcases how Indonesian label converters are embracing advanced flexographic technology to compete in an increasingly sophisticated market. Indolabel’s success provides a model for other converters seeking to modernize their operations while building sustainable competitive advantages.

The company’s commitment to continuous improvement extends beyond equipment acquisition to encompass process optimization, quality enhancement and market development. This holistic approach has enabled Indolabel to maximize the return on its technology investments while building capabilities for future growth.

Future outlook

With its world-class facility, advanced equipment and strong industry partnerships, Indolabel has positioned itself as one of the leaders in the Indonesian market and a significant player across Southeast Asia’s expanding label printing sector. The company’s success demonstrates the potential for domestic converters to compete effectively in regional and international markets through strategic investment and operational excellence.

“This partnership has empowered us to chase our ambition of becoming one of the top label printers in Indonesia”

The continued expansion of Indolabel’s capabilities reflects broader economic trends across Southeast Asia, where growing consumer markets and increasing sophistication in packaging requirements are driving demand for advanced label printing services. The company’s investment strategy positions it to capitalize on these trends while contributing to the development of Indonesia’s manufacturing sector.

Looking ahead, Indolabel’s experience provides valuable insights for other converters considering similar transformations. The importance of strategic partnerships, comprehensive planning and sustained investment in both technology and capabilities emerges as key factors in successful modernization efforts.

The company’s journey from traditional letterpress to advanced flexographic printing illustrates how thoughtful technology adoption can create competitive advantages that extend well beyond immediate operational improvements. By building capabilities that anticipate future market requirements, Indolabel has positioned itself for continued growth in an evolving industry landscape.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.