Q&A: Philippe Voet

Philippe Voet is CEO of Belgium-based label printer Etivoet, a third-generation family-run business founded in 1954. He began a two-year term as president of self-adhesive label association Finat

in June 2021.

L&L: Tell us about your career to date.

Philippe Voet: I qualified as an industrial pharmacist and spent 12 years working as a production manager and then a supply chain manager in the pharmaceutical industry before joining Etivoet – my family’s business – in 2011. So I worked for a potential customer of Etivoet – I know how products are developed, what is important for production and what is important for the supply chain. It means I understand the questions that Etivoet’s customers ask and what they are looking for.

Etivoet is a family business. It was founded by my grandfather in 1954 and my father, Marc, still works there two half-days a week. My brother, Frederik, also works with us, so we are the third generation. When I joined in 2011, I was involved in many different areas of the company. Over time I picked up more responsibilities. I hate job titles and don’t even have one on my LinkedIn profile – what matters is what you are doing. We are all in the same boat.

L&L: How has Etivoet evolved over the years?

Philippe Voet: Etivoet started printing gummed paper labels when it was founded in 1954. The move to self-adhesive label printing took place around 1973-1974 when my father joined the business.

Back then, there were not a lot of label printers. Everyone was doing similar things and had plenty of work. But things became more difficult in the mid-1990s, more competitive. My father began to make some changes, to adapt the business. He started the process, and I helped to continue it when I joined in 2011. My brother joined in 2016, further speeding up the necessary changes. Since then, we run the company together, focusing on product development and innovation.

Before, you just made labels. Now, you need a story. We are trying to create a story: we do the difficult labels. Our niche is how we make a difference. Brands come to us when the labels they want are too complicated for a standard label converter.

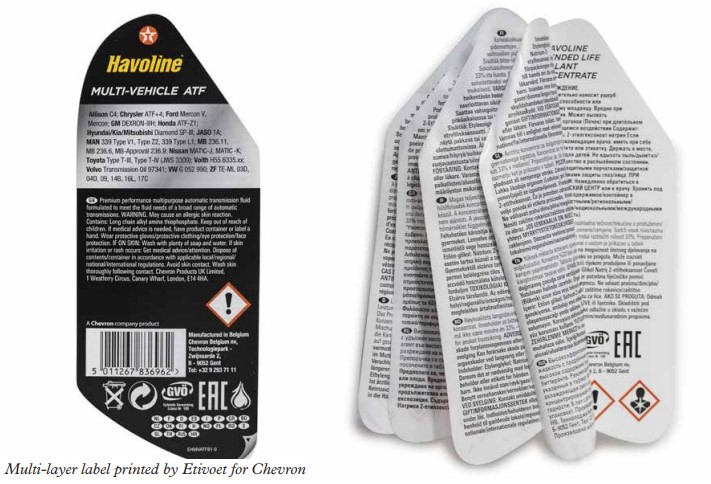

Our main driver is the multi-layer label. Standard label printers might go up to two or three layers; we have a seven-layer label on the market – a 13-page multi-layer label with a fully PP construction, which can compete with the old-school booklet labels.

We use flexo presses from MPS, letterpress from Gallus and digital from HP Indigo and Mouvent. The machines we use are specifically customized for our complex production. Our biggest market is chemicals – industrial and household – which makes up around 35 percent of our production. The food and beverage market accounts for around 25 percent; pharmaceutical labels another 20 percent. The rest is divided into other areas.

Before, you just made labels. Now, you need a story. We are trying to create a story: we do the difficult labels. Brands come to us when the labels they want are too complicated for a standard label converter

These are sectors that currently use a lot of multi-layer labels. But everything always comes in waves. When a different sector begins to pay attention to our products and wants to use multi-layer labels, things change. The key is that we are a partner for our customers – we help them find the correct label for their application, even if this requires development or innovation.

L&L: How did the company adapt during the pandemic?

Philippe Voet: Our first concern was to protect our team. So staff worked from home where possible and we set up a bubble system in production, meaning only small groups of people had contact with each other, to protect the rest of the company. There was full separation of shifts and units.

We had more orders – automotive was down, but hygiene products and household chemicals were up, as was food – but our efficiency was hit because we were protecting staff and the company. Luckily, this was made up for by the increase in work.

L&L: What has been the impact of the supply chain disruption?

Philippe Voet: Everyone has been hit by the supply chain issues. Orders that we are placing now might not arrive for five or six months. Some of our customers would usually order all their labels for the year at the same time. We have to tell them that we can only deliver part of their orders each month, so that we can give something to everyone, otherwise we would run out of stock.

We have to keep getting materials in so that if there is urgency we can react, particularly for the pharma and food sectors But everyone gets a bit less than they want. It is not a fun period for us nor for our customers. It requires creativity, but we are managing the situation.

But as I said before: everything comes in waves. The current problems will push label converters and our customers to keep more stock in their warehouses, but then people will get comfortable again and will reduce their stock again. These things happen in cycles.

I hate job titles and don’t even have one on my LinkedIn profile – what matters is what you are doing. We are all in the same boat

L&L: What area of technology are you likely to invest in next?

Philippe Voet: Our next press will be another flexo press. We are not looking to invest in any new area of technology in particular, but we always look to build on our expertise. Investment happens wherever we need new capacity or new capabilities. Investment in technology always follows the needs of the market. We continuously invest so as to guarantee that we can and will be able to answer the needs of our customers today and tomorrow.

L&L: When Finat announced you as its new president last year, you cited sustainability and talent recruitment as the industry’s two major challenges. Regarding sustainability, do you think enough progress is being made and how can it be accelerated?

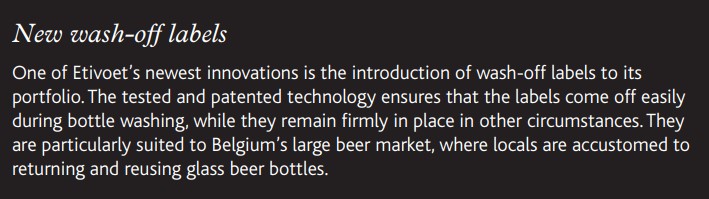

Philippe Voet: I am convinced that labels are the future for sustainability. This is because with the alternatives – such as direct print, for example – you cannot easily separate the ink or the material from the product. A self-adhesive label can be removed. In Belgium, beer is a huge market and we reuse the bottles – this is only possible because you can remove the label, which allows better recyclability. So labels are the future.

But everything happens slowly because change takes time. Until around three years ago, it was rare for a customer to pay more for a more sustainable solution – recycled materials, for example. But now it is happening more often. It is a trend that will only speed up. The market will lead us.

At Finat, we can help to educate people about how to become carbon neutral or to reduce CO2 emissions. This is one area of our work. Another is to help run sustainability projects, as in the work we do for Celab, for example.

L&L: What can the industry do to recruit and retain young talent?

Philippe Voet: We should be more positive. We are working in a fantastic industry. In every shop and home we enter, we see a label that we printed. We are creative and innovative. We need to communicate positively. We are an essential industry. Eighty percent of purchasing decisions are made at the shelf, thanks to the branding and the packaging.

Because of this, I am not negative about attracting new talent to the sector. We are tech-driven. We are on the cutting-edge of sustainability. We just need to communicate differently. The Labelicious competition launched by Finat in 2019 is a perfect example – a positive initiative which shows the possibilities of our industry.

L&L: How do you think the label industry will evolve over the next decade?

Philippe Voet: I could give a standard answer: more digital, and more sustainable. But in the end, I have to say: it depends. Our industry will go where the market takes us. Our challenge is to be ready for the demands of today and tomorrow. We are not the drivers of the market in that respect. We have influence, of course, which is a nice position to be in, but in the end the market decides.

The shift towards sustainability is happening. It’s still a minority, but more and more big companies are coming to us to discuss the possibilities around more sustainable materials, even if it increases their costs. Young consumers will be a driver, because they are more willing to pay extra for sustainable products.

I am convinced that labels are the future for sustainability. This is because with the alternatives, you cannot easily separate the ink or the material from the product. A self-adhesive label Multi-layer label printed by Etivoet for Chevron can be removed

We gained one big customer recently because we have committed to reducing our carbon footprint by 50 percent in the next ten years. At least, the commitment is 50 percent, but in reality our target is much higher, more like 90 percent of Scope 1 and Scope 2 sustainable development performance indicators – SDPIs – which are the ones we can control. These include initiatives such as switching to LED lighting, LED curing, installing solar panels, using electric cars, for example. In the end, it is the sum of small things that can help to make a difference. Switching to LED lighting, for example, has a return on investment of three years, so it is an easy decision. We all should be doing it.

But our suppliers must also reduce their emissions, and the end users as well. How the product is transported and used, and what happens to it afterwards – every step must be considered.

L&L: You were planning to attend Labelexpo Europe, before it was postponed to next year. What will you miss now the show isn’t happening?

Philippe Voet: I will always attend Labelexpo Europe – it is easy for me because I live just 10km from the exhibition halls in Brussels. It’s the go-to exhibition for our industry. For me it has a dual role: seeing equipment and meeting people. I like to be able to get the look and feel of the machinery. It serves as a great filter to narrow down the options: I can see many machines and then decide which ones to further explore. And it is so important to be able to meet the people behind the companies.

We are creative and innovative. We need to communicate positively. We are an essential industry

L&L: What are your main hobbies outside work?

Philippe Voet: I like running – and by that I mean running a lot. I have completed more than 70 marathons and ultramarathons, including some of the toughest races on earth such as the 2016 Marathon des Sables and the 2018 Fire & Ice Ultra. In a similar vein, I also enjoy long-distance hiking. It’s a combination of being good for the health, being outside and interacting with nature, in places that are not easy to get to. It gives me time to think and to organize my thoughts.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.