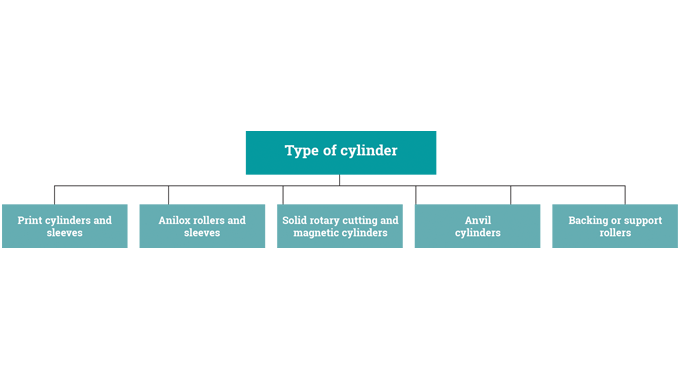

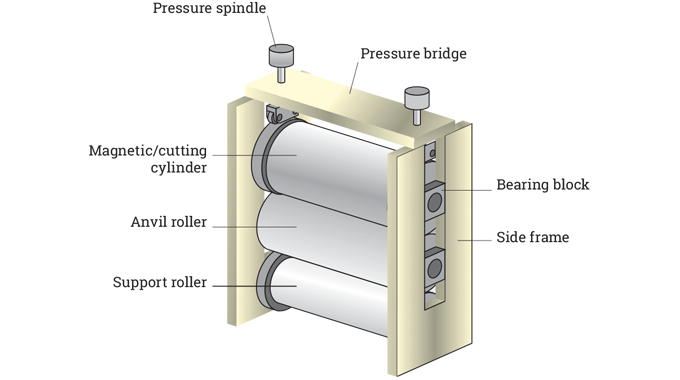

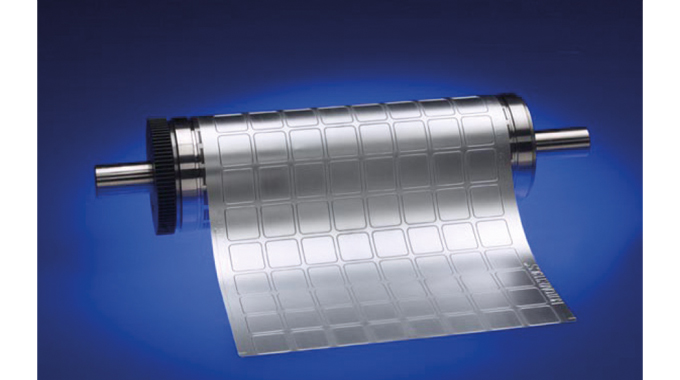

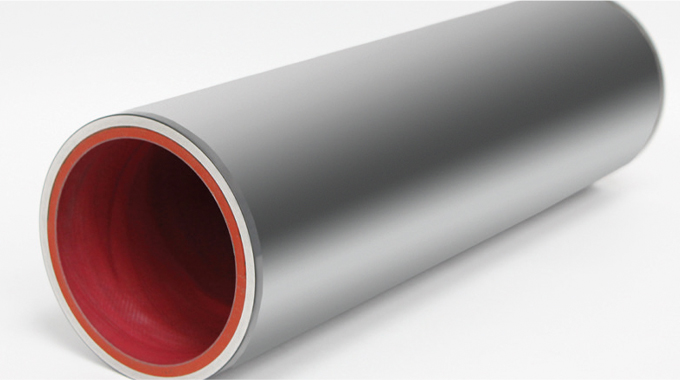

Exploring dies: Cylinders, anvils, support rollers, magnetic cylinders

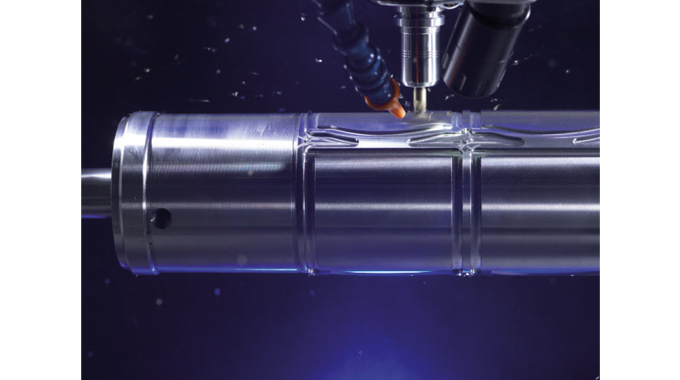

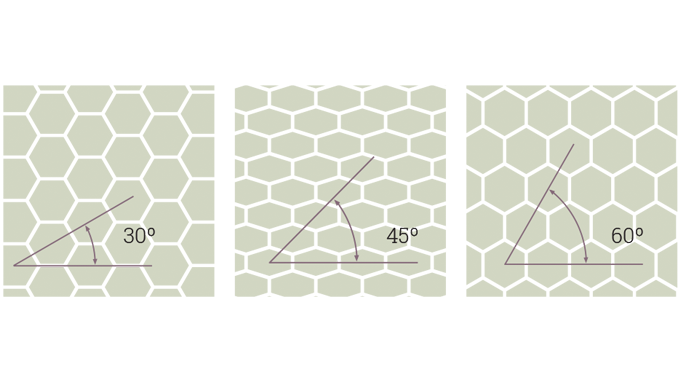

Cutting dies have to be machined and precisely sharpened to very tight tolerances so that they only cut through the layers of material needed. Male and female embossing dies need to mate exactly together to form the necessary embossed or debossed surface structure. Foiling dies also need to be very precise in structure and format to provide clean separation of the foil.

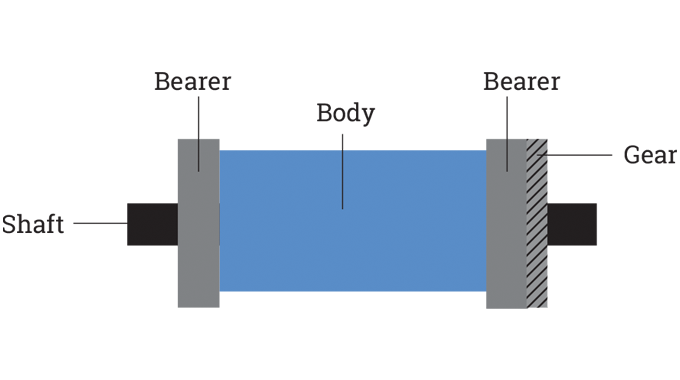

Quite simply, no label or package printing tooling can be manufactured without tight and specified tolerances. Even then, there may be variables in these processes that can have an impact on the final result. This may include set-up, bearers, pressure, distortion, substructure, temperature, materials used, etc. It is important to minimize as many variables in the whole process as possible.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.