Reviewing the hot foiling process

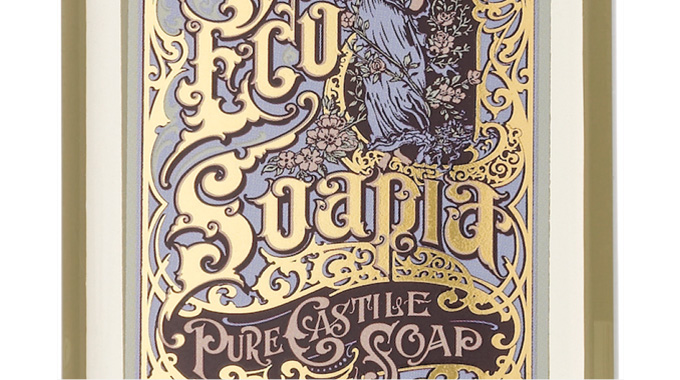

The process of enhancing a product’s prestige and visual attraction with a luxury metallic look, initially gold, is centuries old and traditionally was achieved by the application of gold leaf onto the surface of early manuscripts, scrolls and books by using heated hand tools. This was an expensive, highly skilled and time consuming process and was never feasible for the volume decoration of labels or printed packaging.

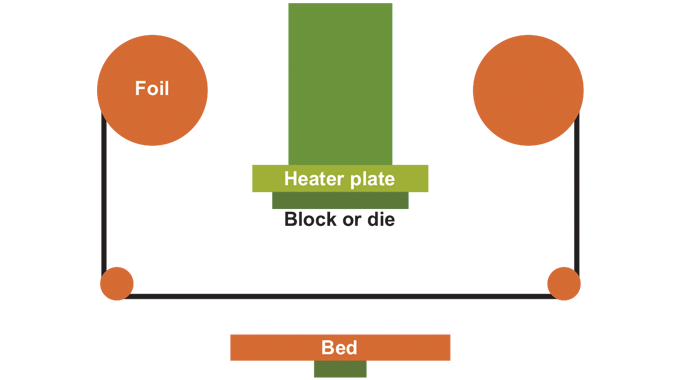

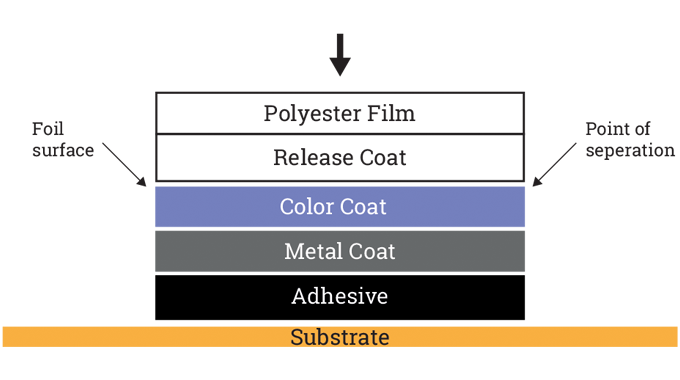

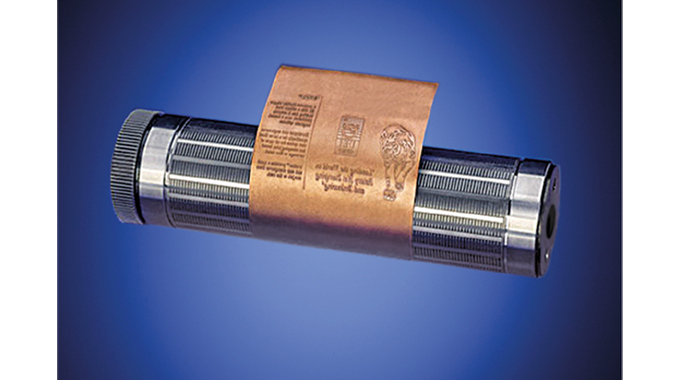

It was not until hot foiling or hot foil stamping, a method of heat transferring a metallic or pigment finish from a carrier strip of paper or film – known as a foil – onto a label substrate using heated dies, pressure and dwell time was first patented back in the 1890s, that the hot foiling process that we would recognise today started to become viable. This first development of the hot stamping process used both gold and coloured stamping foils made from 23 carat gold or bronze powder with a dye to obtain the necessary colour. Both these types of foils were supported on a glassine carrier strip.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.