The nature, use and manufacture of embossing dies and cylinders

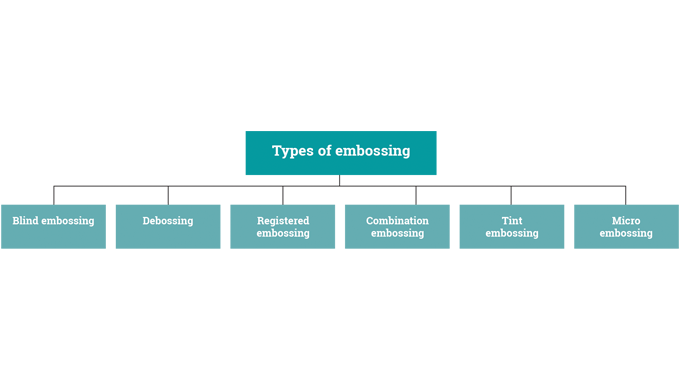

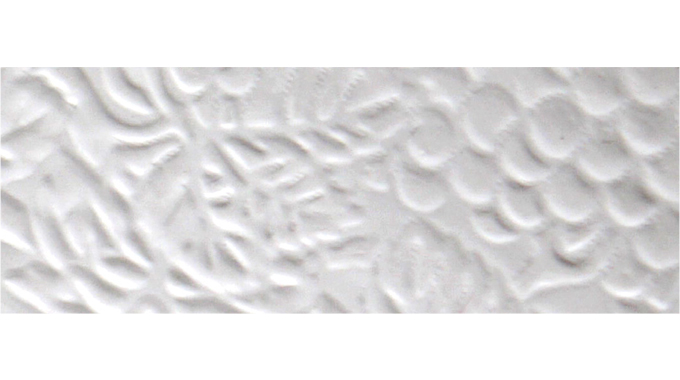

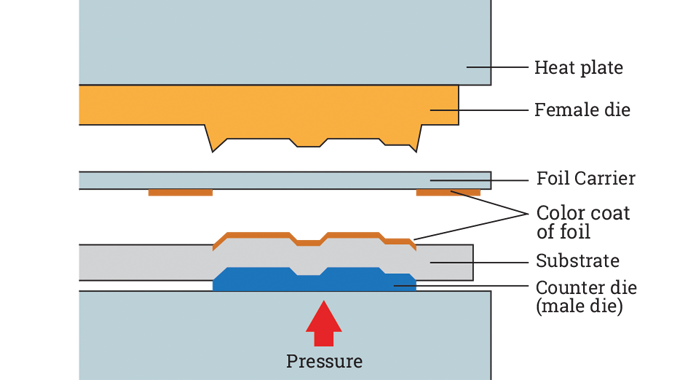

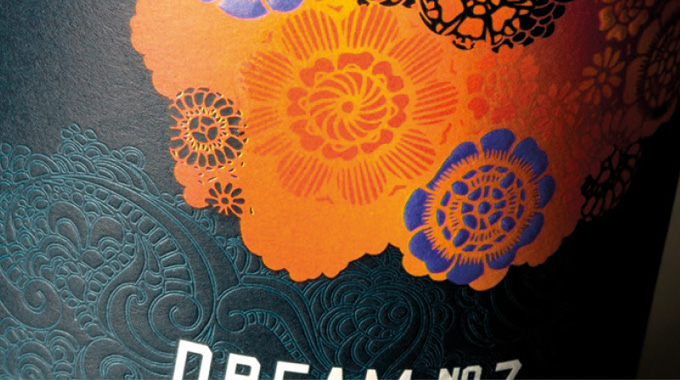

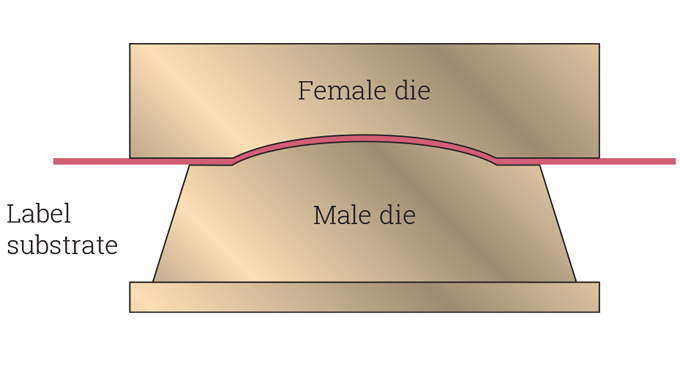

The use of embossing processes to enhance luxury labels and packaging with a raised or tactile image or lettering has become increasingly popular over the years, either used on its own to provide a visual effect through the reflection of light on differing raised image surface levels on an unprinted substrate (blind embossing) or when used in combination with printing and/or foiling (register embossing). Alternatively a relieved emboss/deboss image effect (de-bossing) can be created. Other possibilities today include tint embossing, micro embossing, holographic embossing, polished embossing (glazing), sculptured 3D embossing, continuous textured areas and graining.

These various embossing/debossing processes add a distinctive elegance to many paper-based label stock or carton board substrates used for added-value decoration of wines and spirits, food and beverages, health and beauty, cosmetics, confectionery and personal care products, as well as to some quality wrapping foils, stationery, business cards or even wall coverings. Embossing/debossing is also remarkably effective when used to provide an overall textured effect and in adding impact to something which might otherwise be quite ordinary.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.