Introduction to the self-adhesive label market

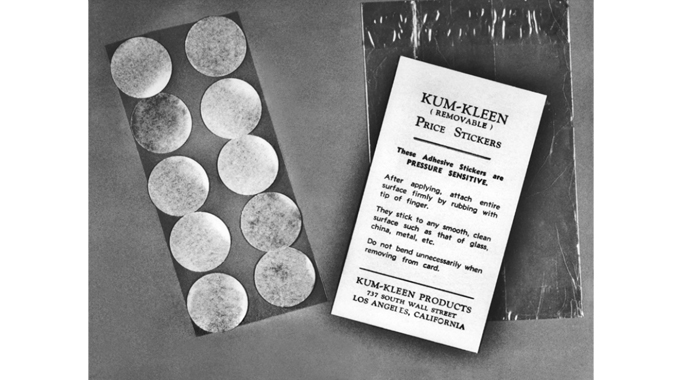

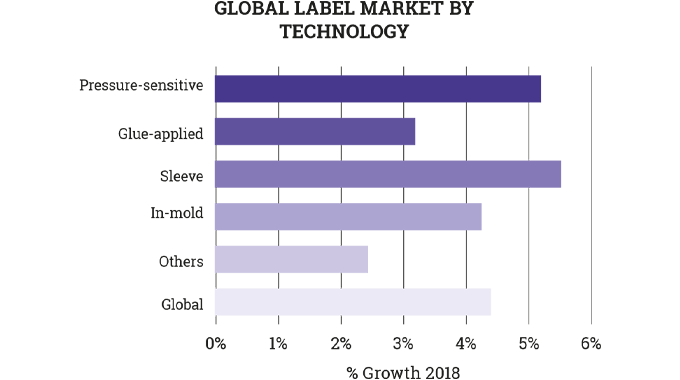

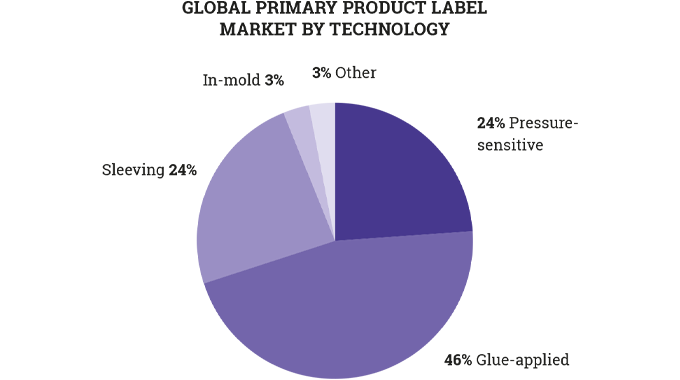

It seems unthinkable in today’s world that we could do without self-adhesive labels, yet they are a relatively modern phenomenon. As recently as 1970 self-adhesive made up less than ten per cent of total label usage in Europe, with label markets dominated by wet-glue applied labels (70 percent) and gummed paper labels (20 percent). Since then self-adhesive labels have experienced consistent and rapid growth worldwide of between 4-7 per year – generally keeping 1-2 percentage points above GDP growth - to become the dominant label technology. (Note that in this series of articles the terms ‘self-adhesive’, ‘pressure-sensitive’ (PS) and ‘pressure-sensitive adhesive’ (PSA) labels are used interchangeably).

Key to this growth has been the flexibility of the self-adhesive label format, with end users able to specify bespoke constructions using a vast range of different materials, top coatings, adhesives and liners. This has allowed end users to meet the challenges of labeling products and containers even in the harshest environments from deep freezers to chemical drums on oil rigs, and from automobile and aerospace to the FMCG retail shelf.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.