Heidelberg expands in-mold label portfolio

Heidelberg has expanded its in-mold label production portfolio by entering into a worldwide distribution agreement with the Japanese AN Corporation for the Kawahara TXS-1100 and Kawahara BMS-1100 automated post-press systems. This marks the global rollout of a pilot agreement concluded for the North American region last year.

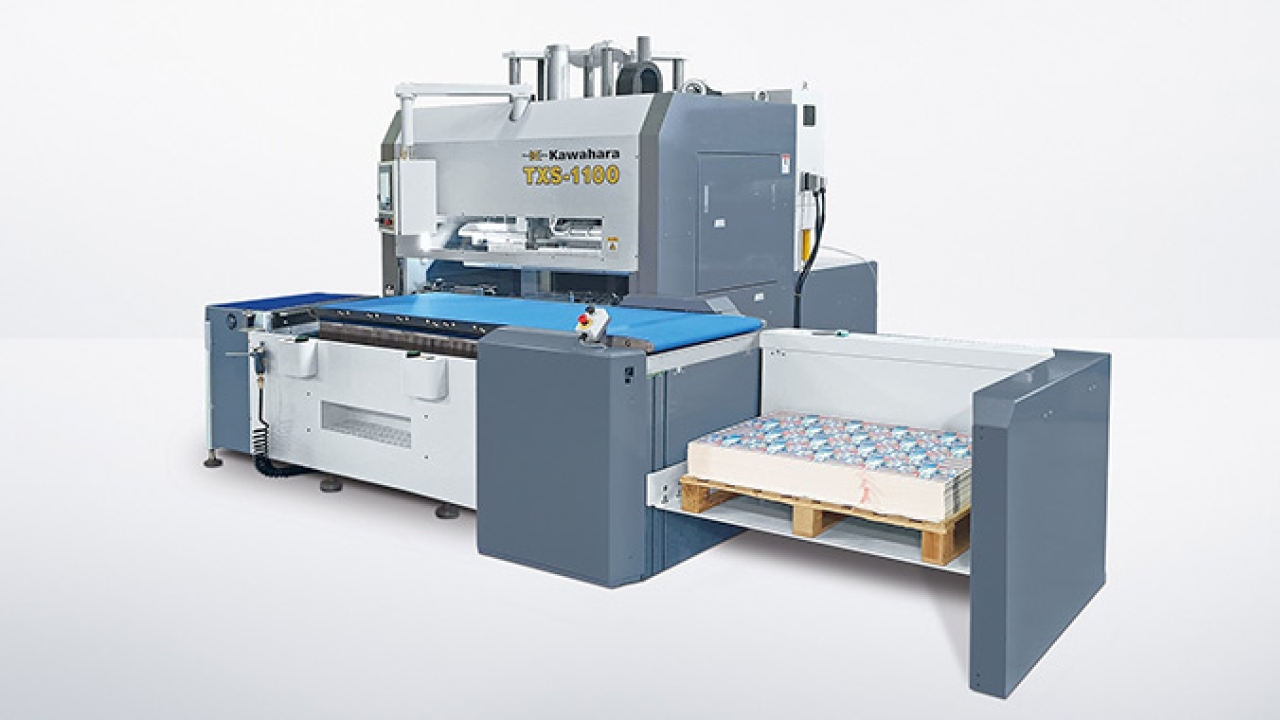

According to Heidelberg, Kawahara blanking systems combine productivity with established technology. The Kawahara TXS-1100 and Kawahara BMS-1100 blanking stations are both high-performance models. Setting up a job takes less than 15 minutes, and tooling costs are minimal. The cycle of the TXS-1100, whereby a stack of 1,000 IML sheets can be quickly blanked and offloaded, takes between 1.5 and 2 minutes.

‘The new Kawahara TXS-1100 is a high-performance system boasting enhanced components and an innovative feeder and unloading system. It is ideal for the in-mold label market and has proved an outstanding stripping and blanking solution for this label material, which is difficult to handle. The Kawahara BMS-1100 offers an excellent price-performance ratio for folding carton print shops that are looking to automate blanking,’ commented Markus Höfer, head of business development for labels at Heidelberg. ‘The BMS-1100 can process up to 20 blank individual stacks of packages per minute and handles single cut and nested products equally well.’

Heidelberg now offers all the technology needed for an efficient workflow in industrial label production – from job creation, pre-press, and plate imaging to printing, die-cutting, and fully automatic blank stripping.

‘Heidelberg is systematically investing in the growth markets of packaging and label printing. The distribution agreement for Kawahara blanking systems adds a further key production step in the workflow to the company’s label printing portfolio,’ said Rainer Hundsdörfer, CEO of Heidelberg. ‘In this way, we are helping our customers further automate their processes and thus make them as efficient and cost-effective as possible.’

Heidelberg and Gallus will be welcoming customers to the Label Day in the Print Media Center at the Wiesloch-Walldorf site in Germany on April 25. One of the technologies on show will be a complete workflow for in-mold label production on a Speedmaster XL 106 press, a Speedmaster XL 106-D rotary die-cutter, and a Kawahara TXS-1100 blanking station.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.