Polar Mohr showcases DC-12 Rapid

German print finishing specialist Polar Mohr has set up its DC-12 Rapid, a fully automated technology for label production at Heidelberger headquarters, where it became an integral part of the showroom and is now available for demonstrations.

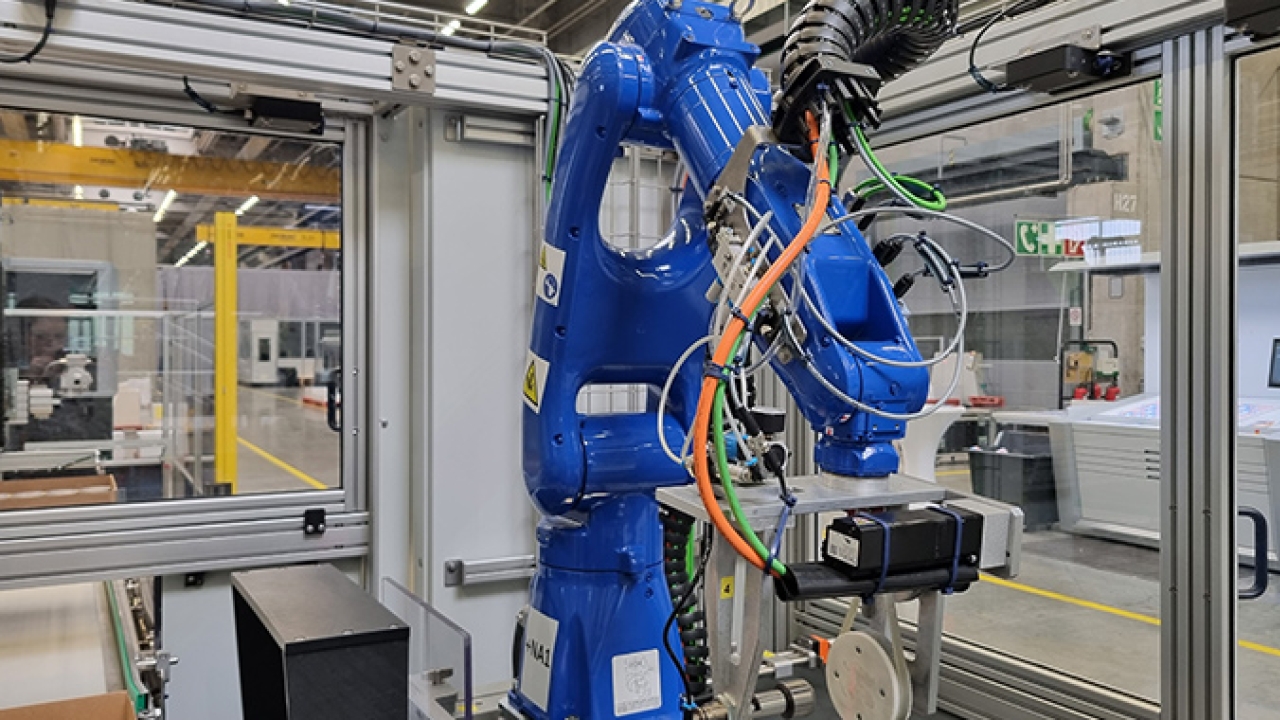

The fully autonomous DC-12 Rapid (Robotics for Autonomous Processing of Industrial Die-Cut Labels), launched virtually in July 2021, produces die-cut label bundles and packs them in trays ready for dispatch. Polar Mohr partnered with packaging specialist Dienst to develop a fully automatic, operator-free process – from the sheet to the tray.

According to the manufacturer, the highly efficient Polar LabelSystem DC-12 Plus is the fastest system on the market, with its ability to process 1440 bundles per hour. It features a system for automatic loading of cutting layers, a cutter for fully automated cutting of strips, and, at the end of the workflow, a sorting and packing station that picks up individual bundles, turns and places them sorted in the tray.

Polar claims that a format change takes only 15 minutes, thanks to the menu-guided job change, the format memory and OptiChange, a patented frame change system. It reduces make-ready times by allowing large parts of the job change to be prepared outside the machine.

The machine also features an intuitive and easy-to-operate system accessible via an HMI that meets the latest industry standards. The company also offers remote support services.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.