Cosmo Films installs wide format lamination machine

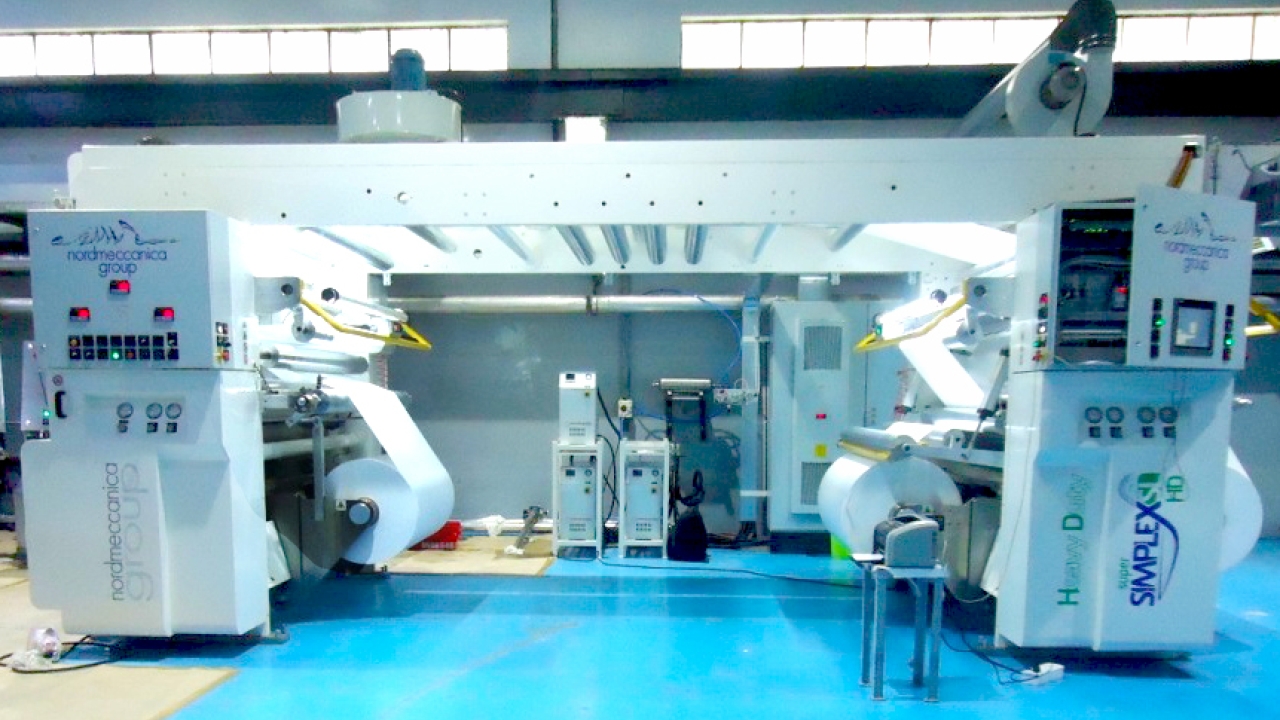

Cosmo Films, a manufacturer of specialty films for flexible packaging, lamination and labeling applications as well as synthetic paper, has installed a new solventless lamination machine at its Karjan plant in Vadodara, India.

The new machine has been commissioned at the company’s facility at Karjan, which already houses BOPP lines, extrusion coating and chemical coating lines and a metallizer. The installed machine, from Nordmeccanica, is 1.8 meters wide and can run at speeds of up to 450m/min. The machine can produce multilayer film laminates up to a thickness of 450 micron. The laminate could be a combination of different materials such as PP, PET, PE, nylon, aluminum foil or paper. A dedicated sheet cutter of the same width has also been installed next to the machine to process its output.

As the machine can laminate structures as thick as 450 microns, it helps the company serve customers requiring thick film laminates. Some of the applications areas of thick laminates include graphic arts, baggage tags, retort and stand-up pouches, high-strength hanging labels, aseptic boxes and luncheon trays, composites for construction and auto-segment etc. The machine can also help the company with R&D testing during new product development.

Pankaj Poddar, CEO of Cosmo Films, said: ‘Solventless lamination machine is the latest addition to our R&D portfolio; also available for our customers having thick lamination needs. Moreover, solventless lamination being an eco-friendly process with no emissions and low energy demands would also help us with our sustainability goals.'

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.