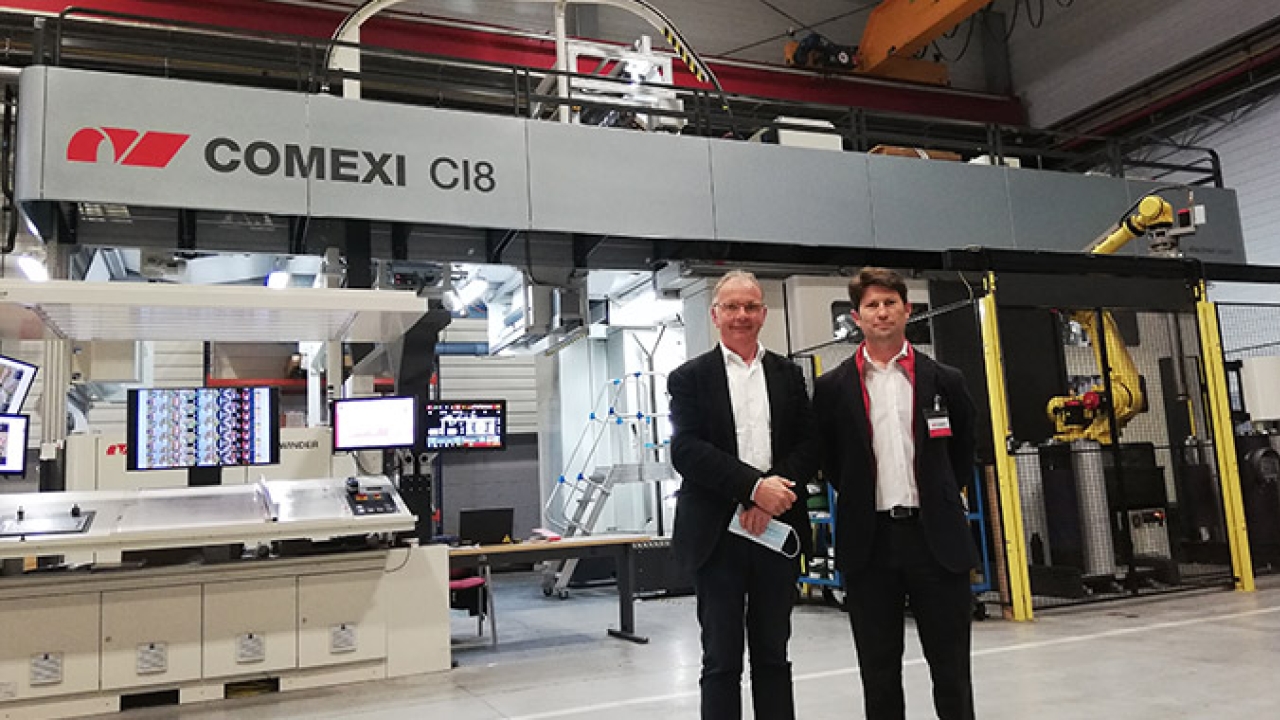

Jiménez Godoy acquires second Comexi offset press

Jiménez Godoy has invested in a Comexi Offset CI8 press to increase its production volume and attract new clients. This is the second Comexi offset press purchased by the Spanish converter.

Jiménez Godoy is a Spanish family-run business with over 50 years of experience in the printing and graphic arts sector. The company is dedicated to printing a vast range of plastic and paper products, such as labels, catalogs, leaflets, and flexible packaging for various industries, including food, pharmaceutical, and entertainment.

‘In recent years, we have experienced significant growth, partly due to the purchase of our first Comexi Offset CI8. The acquisition of a second offset press will allow us to increase production volume and offer our clients productive security, which will simultaneously attract other companies,’ said Francisco Jiménez, managing director of Jiménez Godoy. ‘Continuous collaborative growth with an experienced company such as Comexi is our objective.’

The Comexi Offset CI8 press combines the advantages of offset variable size printing with central drum technology. As a result, it is suitable for short and medium-sized runs. According to Comexi, it responds to the demand of time to market and printing quality, reducing operative cost.

The offset central impression printing technology is a two-fold environmentally responsible option, as print is done without solvents and frontal printing, with EB (Electron Beam) protective varnishes, allows for the replacement of laminated products or the reduction of the number of layers due to the capabilities of chemical, thermal, and scratch-resistance of EB lacquers. Effectively, this facilitates the sealing of monofilm products and the recycling of packaging. The EB curing system consumes low energy and provides high productivity, with low migration inks and low odor.

‘Comexi's central drum offset printing allows to be faster, regarding both pre-press and job changeover. The cost of pre-press is considerably lower than other conventional printing technologies, as a new job can be executed in less than two hours, and an entire set of seven plates can be accomplished in under 20 minutes,’ commented Felip Ferrer, offset brand manager of Comexi's printing business unit.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.