JTape installs Mark Andy Digital One to personalize face shields

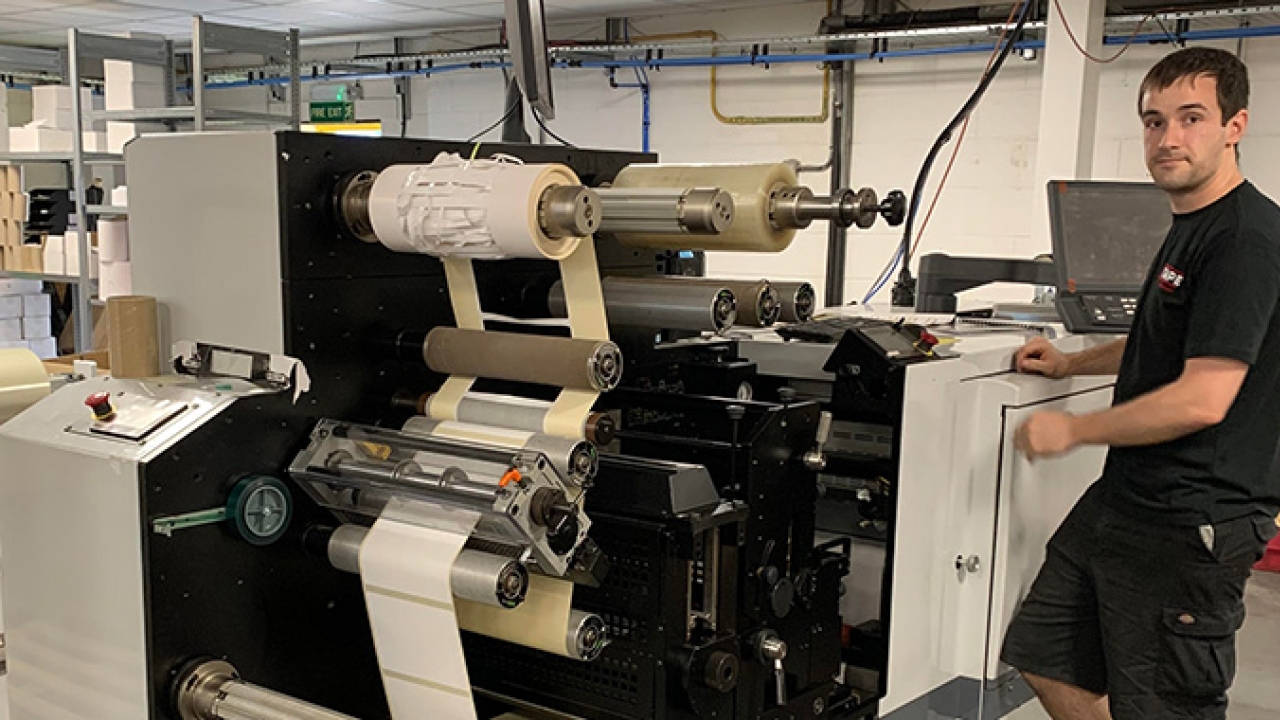

UK-based manufacturer of masking products for commercial applications JTape has invested in our Digital One press to print personalized face shields and extend their PPE product range.

Established in 2003, JTape now employs over 40 people, manufacturing and producing 50 individually designed products to automotive, marine, aerospace, construction, industrial, rail, trade and creative sectors.

With the dramatic effect that the Covid-19 pandemic has had on many of its traditional markets, the company turned to a range of new PPE and safety products for medical, business and personal use.

The face shields are printed directly onto the clear section of the visor, with user instruction QR code, the CE certification mark that confirms the product meets the regulatory requirements for PPE use in the EU, and face shield FDA product listing for approved use in the USA. Customers can choose from one of JTape’s bespoke designs or provide their own design or logo to promote their brand.

‘We were looking for a simple, quick and practical solution that offered a high print quality to match that of our face shields and other products,’ said Oliver Jevons, owner of JTape. ‘Mark Andy was able to supply and install the Digital One press straightaway and we were in production the same day.’

Mark Andy sales manager Paul Macdonald commented: ‘We were delighted to be able to assist JTape at such short notice and our Digital One is an ideal machine for their specific application – it’s easy to use and produces high quality print from its toner-based engine. This installation typifies the broad appeal that we have tapped into with our range of digital technology.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.