Enprom launches eRS2T3 sleeve seaming equipment

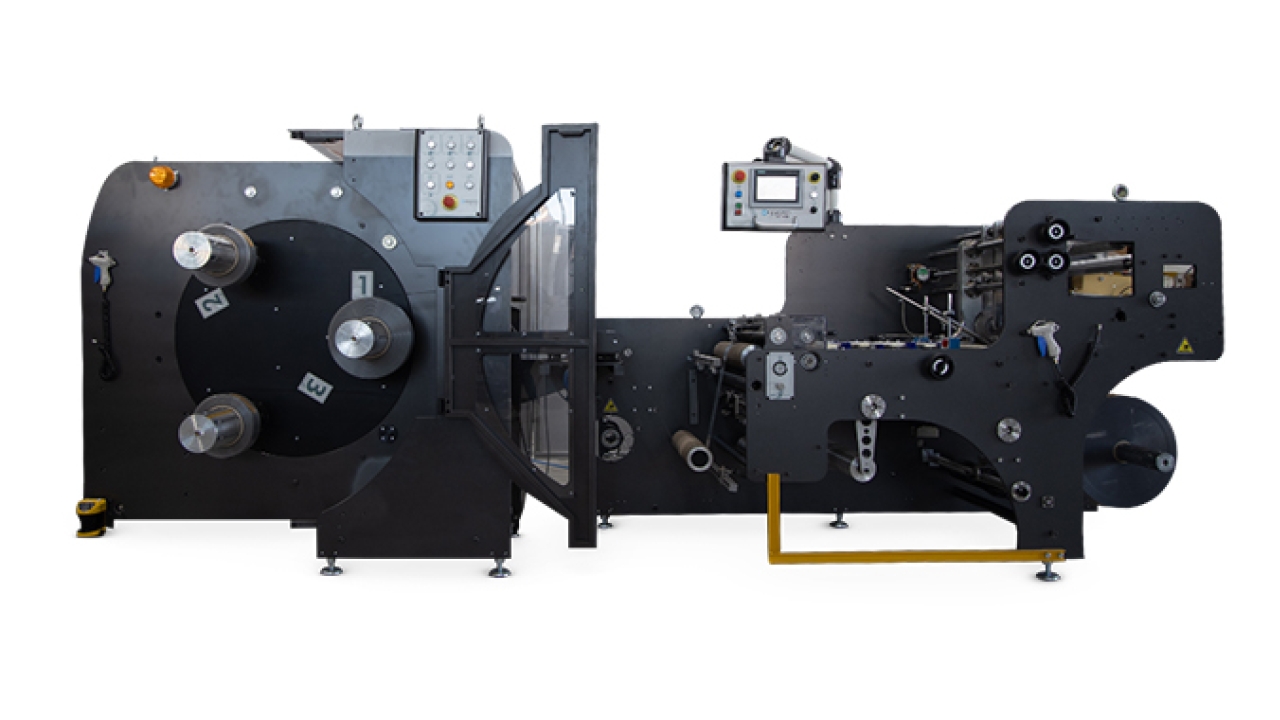

Enprom, one of the leading Spanish converting equipment manufacturers, has launched an eRS2T3 sleeve seaming machine featuring its patented Smart Wheel system and a non-stop three-shaft turret rewinder.

The new machine features a non-stop three-shaft turret rewinder and is based on Enprom’s patented Smart Wheel innovation - a motorized roller solvent application system providing high seaming reliability.

The eRS2T3 has been developed to meet the high productivity demands of the labelling market. The new machine is driven by eight servo motors and includes two independent tension controls on both the unwinder and rewinder to avoid errors and alterations in the width of the labels.

Designed to perform splices at 500m/min (1640ft/min), the time required to perform a reel discharge cycle is reduced by almost 50 percent, thereby enabling high speed functionality controlled by a single operator. Moreover, the eRS2T3 includes advanced ergonomics and provides an increased focus on safety, incorporating an infrared optical barrier to safeguard operators.

Accroding to Enprom, this latest development can contribute to improving productivity, increasing efficiency, quality and reducing operating cost by 15 percent.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.