Improved flexible dies for flexible packaging

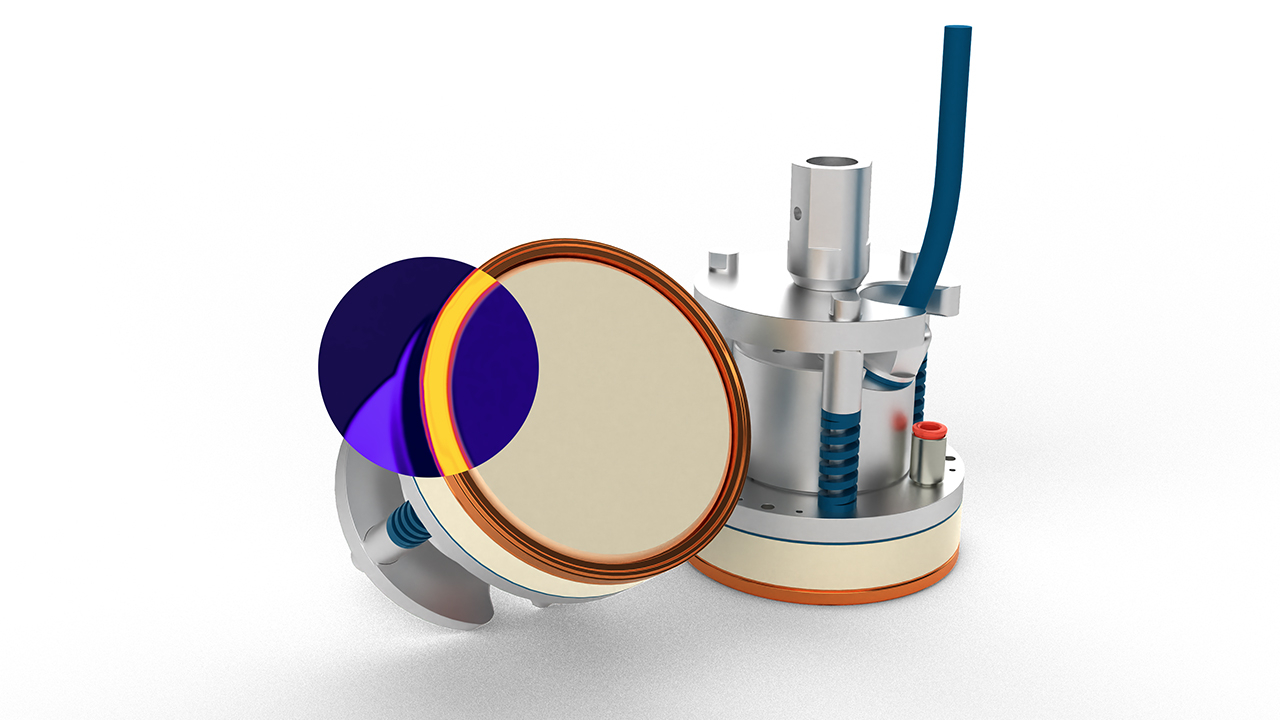

A new line of 7* (17cm) flexible dies suitable for rotary conversion of film, foils, paper, cardboard and non-woven −including abrasive and difficult materials – is being launched by Gerhardt, the specialist in rotary tooling.

The new dies have a long life thanks to an extremely wear-resistant coating that has a very low co-efficient of friction property and have been designed for short set-up times on converting equipment and for cost-efficient production of flexible packaging.

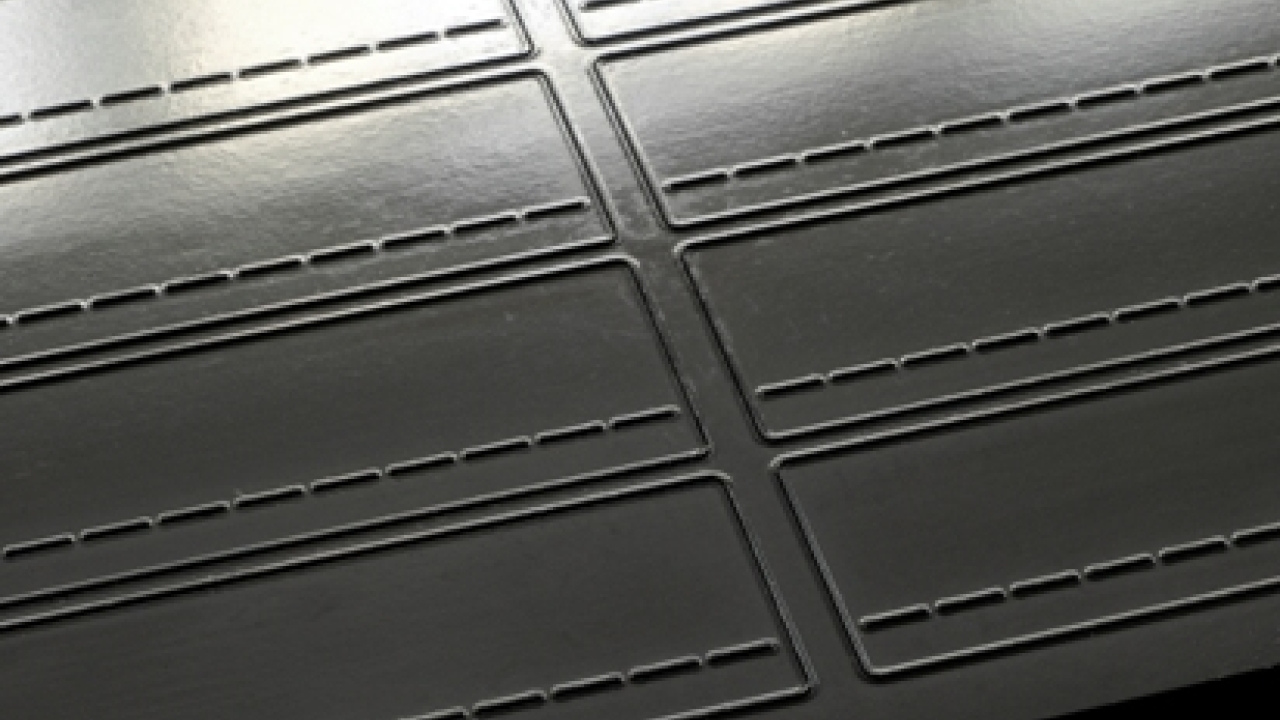

The dies are also highly recommended for converting abrasive materials such as thermal transfer, materials with an aggressive or fluid adhesive, labels being printed with abrasive inks/coatings, and for companies wanting to convert very long runs. Tests show up to seven times longer runs than with normal hardened EDM dies.

The High Blade Flexi version of the dies enables web converting of materials with a caliper up to 0.9 mm and up to 3-5 mm if they compress. This ensures cost-effective converting for applications like foamic constructions, cardboard, gasket materials, booklet labels, and medical devices.

Gerhardt International is one of the world’s leading suppliers of rotary tooling, with production and offices in five continents, supporting a wide range of industrial sectors.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.