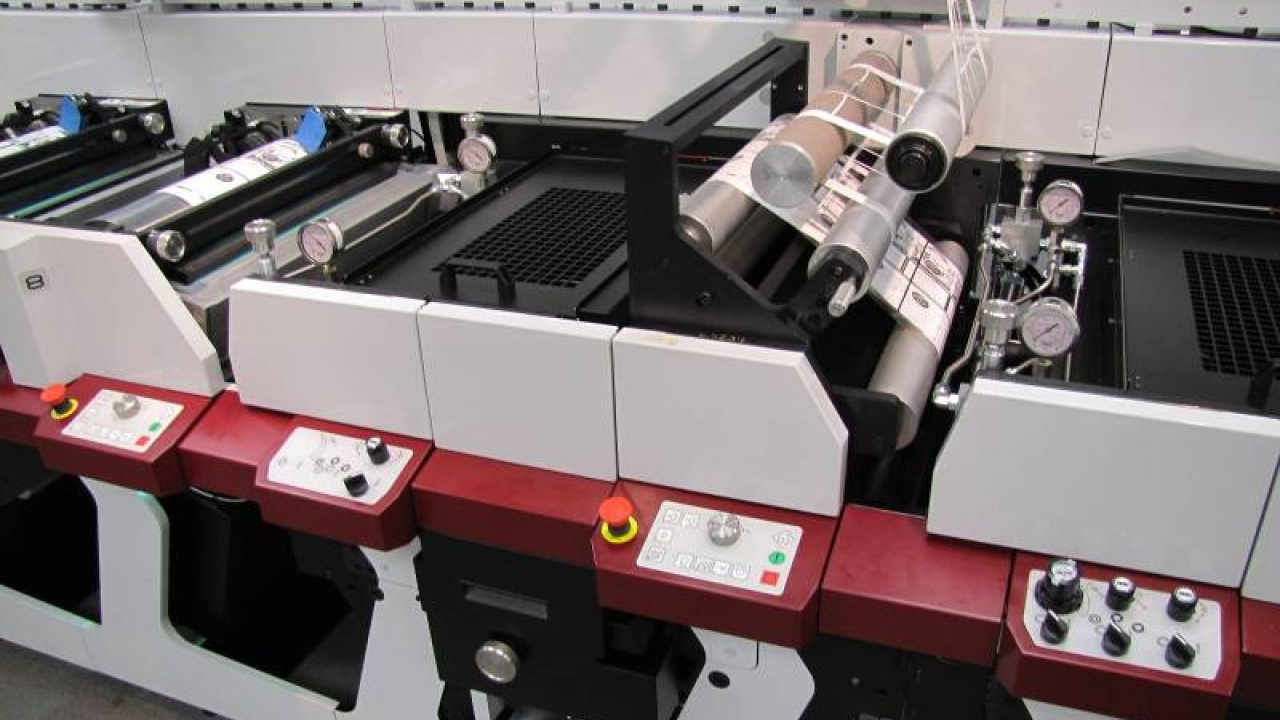

Mark Andy unveils QCDC die-cutting technology

Mark Andy has launched its QCDC (quick change die-cut) converting platform.

The company describes QCDC as a new design in die-cutting technology that promises faster die set-up and changeover as well as precision cut accuracy. It claims that operators will be able to reduce set-up times by 60 percent thanks to QCDC’s die cassette workflow, open guarding system, simple matrix web path and superior ergonomics.

Available in a single- or dual-die station configuration, the QCDC allows for dies to be loaded, automatically registered with servo technology, and quickly running full production. Die exchange is facilitated by a quick change cart, specifically designed for the Performance Series platform. The station’s design allows for accurate loading of dies either off-line during job changeover (single die station) or in a second station while the press is running a job (dual die station), further enhancing production efficiencies for the converter.

Mark Andy says QCDC will also aid considerably in waste savings. The system’s design offers trouble-free matrix stripping and winding to reduce web breaks, as well as enabling customers to easily strip difficult die shapes. QCDC can easily adapt older Mark Andy dies as well as most dies from other press manufacturers. The adaption design provides rigid mounting of narrower adapted dies, providing consistent die quality.

QCDC technology will be demonstrated on both the Performance Series P5 and P7 models on the Mark Andy stand (#319) at Labelexpo Americas 2012.

Pictured: New Mark Andy QCDC two-station module shown on a Performance Series P7

Click here for more stories about Mark Andy on L&L.com.

Click here for more stories about Labelexpo Americas on L&L.com.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.