Videojet upgrades 9550 system with 6in printhead

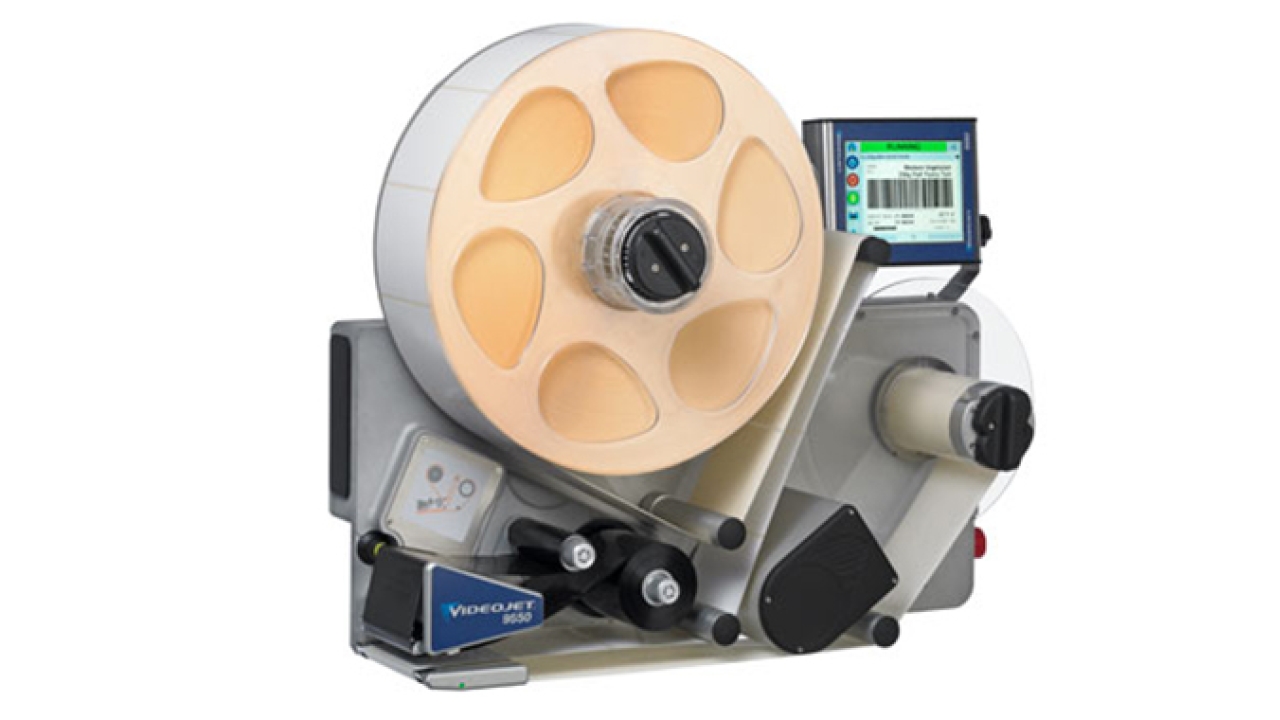

Videojet Technologies has upgraded its 9550 Label Print and Apply (LPA) system for direct apply labeling applications with the new 6in printhead option, building on a success of 2 and 4in models.

The 9550 design removes the mechanisms that frequently cause operational problems, such as label jams and routine manual adjustments. The machine places the label onto the pack without the need for a tamp or air blast applicator, achieving throughput of up to 150 packs per minute for typical 4 x 6in GS1 barcode labels, depending on environment, label quality and substrate.

By incorporating Intelligent Motion technology, the entire system is precisely and electronically controlled, targeting zero unscheduled downtime on production lines. The direct drive system feeds and places labels accurately even at high line speeds without the use of manual adjustments, clutches or nip rollers. No adjustments means that only two operator touches are now required to manage job selection and web changeover, complemented by a collapsible mandrel to ensure quick label changes.

The unique design removes the need for complex applicators for mainstream top or side label applications, reducing the number of labels being incorrectly applied or mangled during application.

In order to help manufacturers improve quality and adhere to applicable standards, the 9550 comes equipped with the Clarity touch screen interface which displays job selection, comprehensive feedback and diagnostics to minimize human error.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.