Dies and tooling: Inspecting, cleaning, handling, storage and safety considerations

Any operations that involve the handling, setting up, cleaning, inspection or storage of cutting, embossing, foiling, sheeting or perforating tools – even cylinders, anvils and support rollers – has the potential to either damage the tooling or cause a safety or health risk to the workforce. This applies whether the tooling is flatbed, solid rotary or flexible. Some operations and tools however, are perhaps more likely to cause damage or safety risks than others.

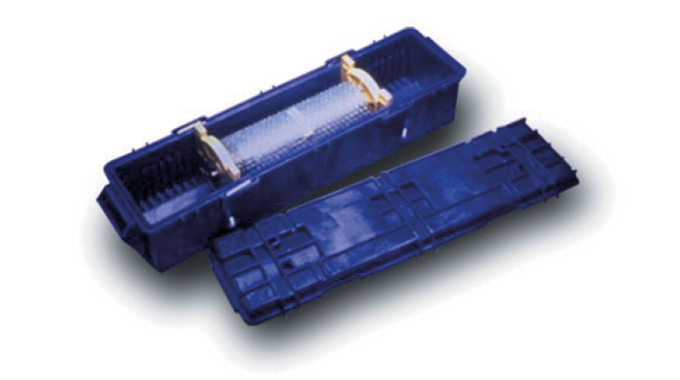

In particular, the manufacture and use of tooling at the finishing end of a roll-label press often involves engineered products that can be heavier, harder to handle, bulkier and potentially more likely to be damaged or cause damage than in many other label production applications. Quite simply, moving and handling precision engineered tools during manufacturing or in warehouse, production or storage areas requires specific expertise and training.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.